Electrical Controls and Wiring — Electrical con-

trols are difficult to check without proper instrumentation;

therefore, if there are any discrepancies in the operating cycle,

contact your dealer and request service.

Refrigerant Circuit — The refrigerant circuit is diffi-

cult to check for leaks without the proper equipment; there-

fore, if inadequate cooling is suspected, contact your local

dealer for service.

Combustion Area and Vent System — The com-

bustion area and vent system should be inspected visually

before each heating season. The normal accumulation of dirt,

soot, rust, and scale can result in loss of efficiency and im-

proper performance if allowed to build up.

If your unit makes an especially loud noise when the

main burners are ignited, shut down the heating section

and call your dealer.

Proceed as follows to inspect the combustion area and power-

venting system of your unit.

1. Turn off electrical power and gas supply to your unit.

2. Remove burner access panel. (See Fig. 1.)

3. Using a flashlight, carefully inspect the burner areas for

dirt, soot, rust, or scale. See Fig. 2.

If dirt, soot, rust, or scale accumulations are found,

call your dealer and do not operate your heating sec-

tion.

4. When you have completed your inspection, follow the

start-up procedures in this manual to restore your unit to

operation.

5. Observe unit heating operation.

Components in heat section may be hot after unit

has been started up. When observing flame, be care-

ful not to get close to or touch heating components

or serious personal injury may result.

Watch the burner flame to see if it is bright blue. If you

observe a suspected malfunction or if the burner flames

are not bright blue, call your dealer.

6. Replace burner access panel.

Unit Panels — After performing any maintenance or serv-

ice on the unit, be sure all panels are fastened securely in

place to prevent rain from entering unit cabinet and to pre-

vent disruption of the correct unit airflow pattern.

REGULAR DEALER MAINTENANCE

In addition to the type of routine maintenance you might

be willing to perform, your unit should be inspected regu-

larly by a properly trained service technician. An inspection

(preferably each year, but at least every other year) should

include the following:

1. Inspection of all flue product passages — including the

burners, heat exchanger, and flue collector box.

2. Inspection of all combustion- and ventilation-air pas-

sages and openings.

3. Close inspection of all gas pipes leading to and inside of

your unit.

4. Inspection and, if required, cleaning of the condenser

and evaporator coils.

5. Inspection and, if required, cleaning of the evaporator

drain pan.

6. Inspection and cleaning of blower wheel housing and

motor.

7. Inspection of all supply-air and return-air ducts for leaks,

obstructions and insulation integrity. Any problems found

should be resolved at this time.

8. Inspection of the unit base to ensure that no cracks, gaps,

etc., exist which may cause a hazardous condition.

9. Inspection of the unit casing for signs of deterioration.

10. Inspection of all electrical wiring and components to as-

sure proper connection.

11. Inspection for leaks in the refrigerant circuit. Pressure-

check to determine appropriate refrigerant charge.

12. Inspection of compressor oil level.

13. Operational check of the unit to determine working con-

ditions. Repair or adjustment should be made at this time.

Your servicing dealer may offer an economical service con-

tract that covers seasonal inspections. Ask for further

details.

Complete service instructions can be found in the unit

Installation, Start-Up and Service Instructions.

WARRANTIES

Units 48SS and 48SX each have a separate warranty lo-

cated at the back of this book. Be sure to read the warranty

carefully to determine the coverage for your unit.

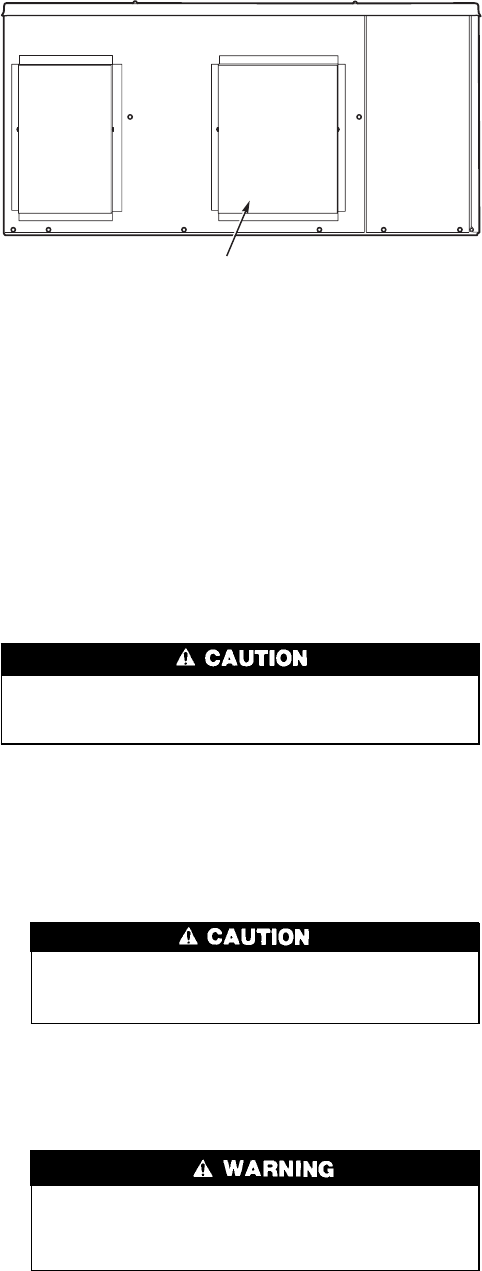

Fig. 5 — FilterAccess Panel — Vertical Supply Shown

FILTER ACCESS PANEL

7