8

INSTALLATION

Mixing Box

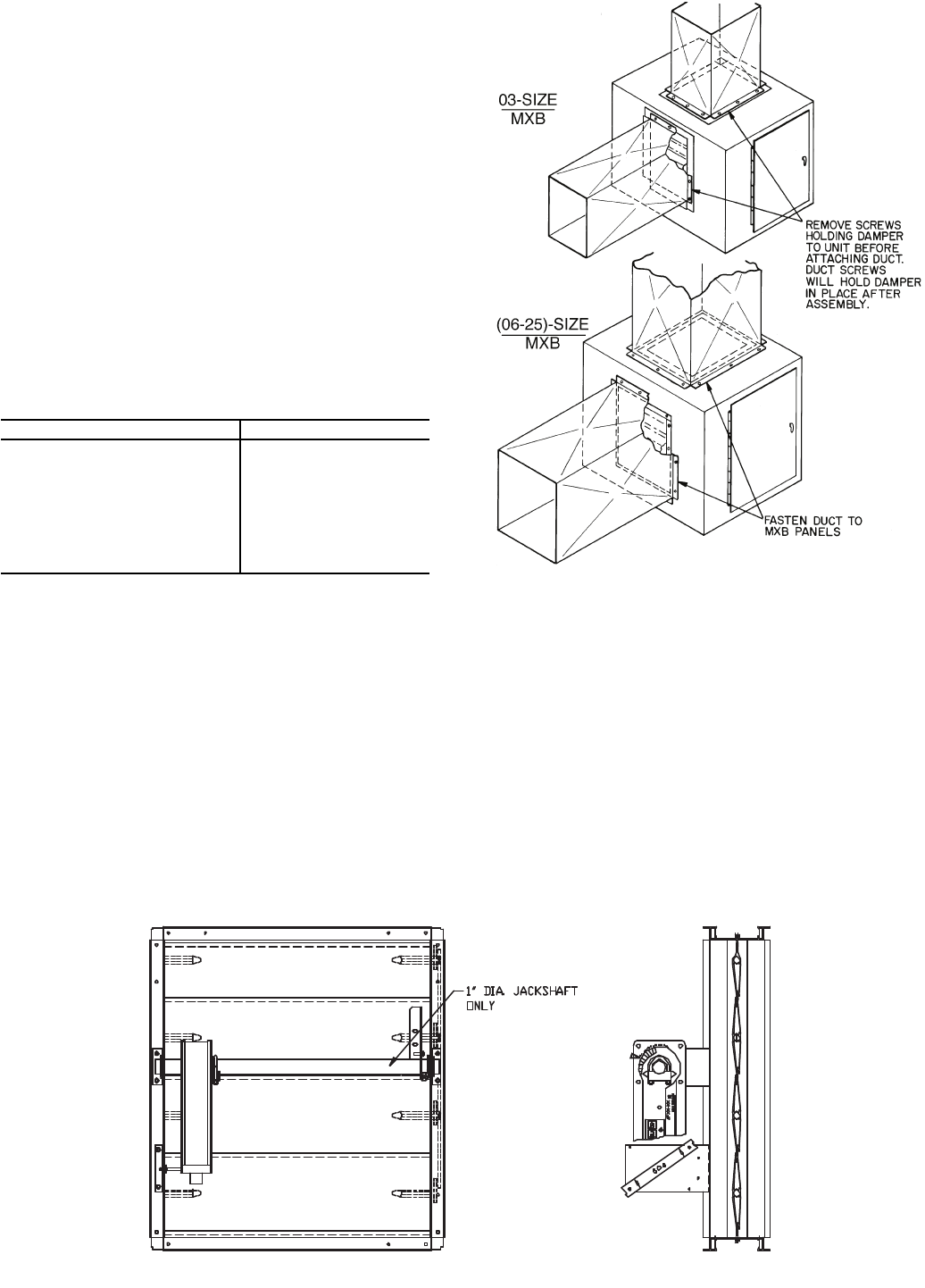

DAMPER ACTUATORS — The 39L mixing boxes are sup-

plied with low leak dampers and blade and edge seals. Damper

operating torques are shown in Table 2.

The actuator and mounting brackets are field supplied and

may be mounted inside or outside the unit. A typical inside

mounting bracket is shown in Fig. 8. For external mounting of

actuators, drill or punch a hole in the exterior panel.

NOTE: If the unit is shipped with AirManager™ controls,

actuator(s) are factory-supplied. Refer to Table. 3.

To ensure torque is transmitted equally to both damper sec-

tions, actuator must be connected to the 1-in. hollow jackshaft

that drives the interconnecting linkage bar. Connection to any

other shaft is not recommended.

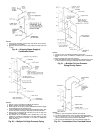

DUCTWORK ATTACHMENT — Ductwork should be

flanged out and attached to the mixing box panels as shown in

Fig. 9. See Fig. 10 for duct connection sizes.

Table 2 — Mixing Box Damper Operating Torque

(in.-lb)

NOTES:

1. Torque values are based on interconnected dampers driven by

one operator. For units with separate operators for each

damper, calculate torque as follows: Table values x .80 = torque

per damper section.

2. Damper shaft moves 90 degrees from open to closed position.

Condensate Drain — Install a trapped condensate drain

line at unit drain connection. Use 1-in. standard pipe.

Measure maximum design negative static pressure up-

stream from the fan. Referring to Fig. 7, height “H” must be

equal to or larger than negative static pressure at design operat-

ing conditions. Prime enough water in trap to prevent losing

seal (Differential 1). When the fan starts, Differential 2 is equal

to the maximum negative static pressure.

Provide freeze-up protection as required.

39L UNIT SIZE TORQUE

03 20

06 20

08 26

10 29

12 33

15 41

18 52

21 56

25 76

MXB — Mixing Box

Fig. 9 — Mixing Box Ductwork Attachment

Fig. 8 — Typical Mixing Box Actuator Mounting