29

START-UP

Check List —

Make a walkway inside unit components to

protect insulation. Remove all construction debris from unit

interior. Remove walkway before starting unit.

FILTERS — Install unit filters in all filter sections.

FANS

1. Check lubrication of fan, motor bearings, and linkages.

a. Note that bearings are shipped completely full of

grease for corrosion protection and may run warm

temporarily on start-up until excess grease has

discharged.

b. Hand-operate all linkages, such as damper and

guide vanes, to check for freedom of movement.

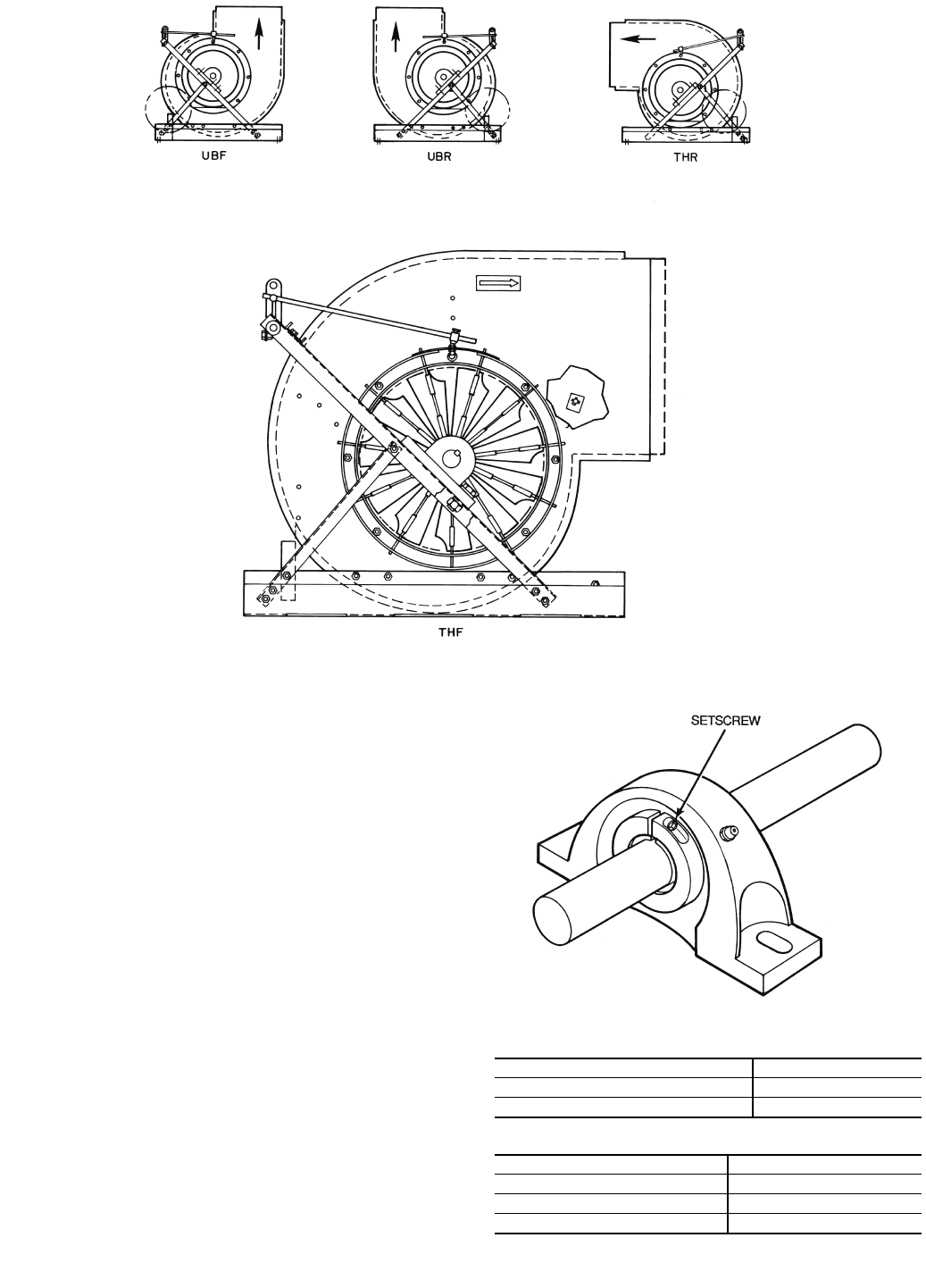

2. Check tightness of bearing setscrews or locking collars

(Fig. 35). Also, check tightness of setscrews on fan

wheels and sheaves.

3. Check tightness of fan shaft bearing mounting.

4. Recheck sheave alignment and belt tension. (Refer to

Fig. 14 and 15.)

5. Hand turn fan to make certain fan wheel does not rub in

housing.

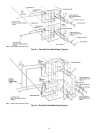

Fig. 34 — Fan Discharge Positions, Fans with IGVs

LEGEND

THF — Top Horizontal Front

THR — Top Horizontal Rear

UBF — Upblast Front

UBR — Upblast Rear

SQUEEZE-TYPE LOCKING COLLAR

BEARING SETSCREW TORQUE (in.-lb)

BEARING HOLDDOWN BOLT TORGQUE (ft-lb)

Fig. 35 — Fan Shaft Bearing Details

39L UNIT SIZE TORQUE

03,06,08,10,12 70

15,18,21,25 90

BOLT SIZE TORQUE

3

/

8

-16 30

1

/

2

-13 63

5

/

8

-11 100