5

Install Electrical Accessories

Refer to the individual instructions packaged with kits or

accessories when installing.

Start--Up

CAUTION

!

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal

injury .

Wear safety glasses, protective clothing, and gloves when

handling refrigerant and observe the following:

S Front seating service valves are equipped with Schrader valves.

CAUTION

!

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental

damage.

Federal regulations require that you do not vent refrigerant to

the atmosphere. Recover during system repair or final unit

disposal.

CAUTION

!

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this caution may result in personal injury ,

equipment damage or improper operation.

S Do not overcharge system with refrigerant.

S Do not operate unit in a vacuum or at negative pressure.

S Do not disable low pressure switch in scroll compressor

applications.

S Compressor dome temperatures may be hot.

Follow these steps to properly start up system:

1. After system is evacuated, fully open liquid and vapor

service valves.

2. Unit is shipped with valve stem(s) front seated (closed) and

caps installed. Replace stem caps after system is opened to

refrigerant flow (back seated). Replace caps finger--tight and

tighten with wrench an additional 1/12 turn.

3. Close electrical disconnects to energize system.

4. Set room thermostat at desired temperature. Be sure set

point is below indoor ambient temperature.

5. Set room thermostat to HEAT or COOL and fan control to

ON or AUTO mode, as desired. Operate unit for 15

minutes. Check system refrigerant charge.

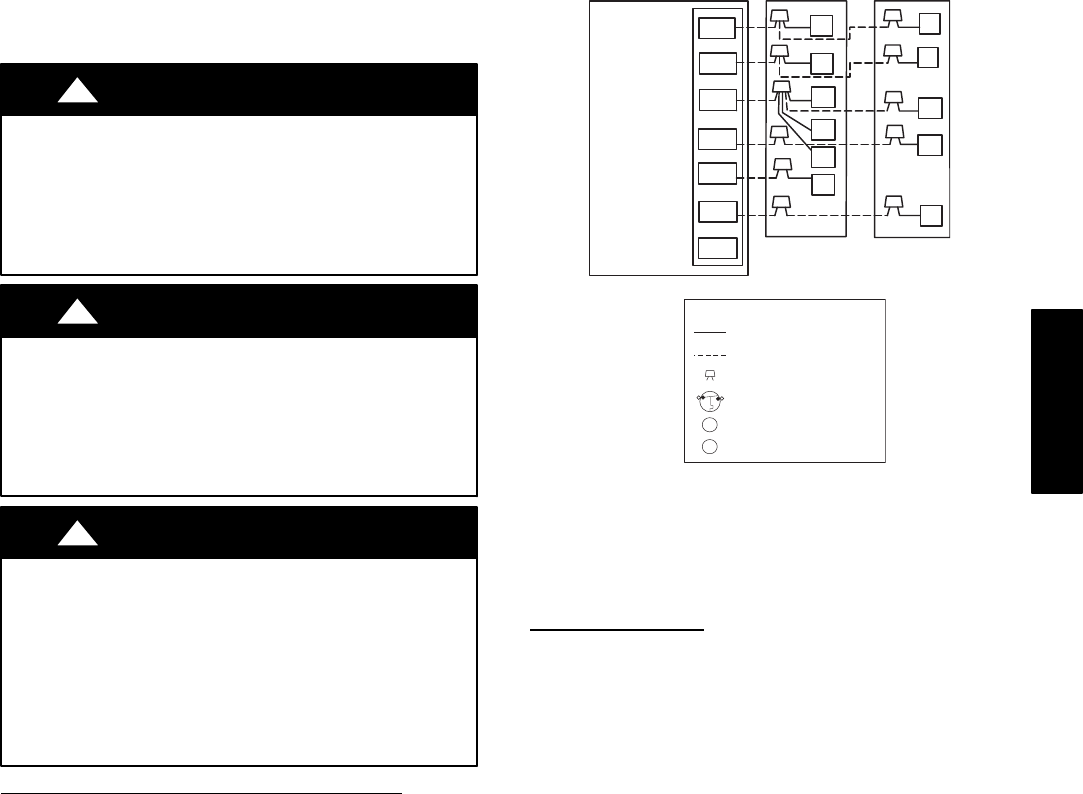

24 VAC HOT

R

C

W2

Y

G

R

C

RVS COOLING

C

W2

HP THERMOSTAT

TYPICAL

FAN COIL

HEAT

PUMP

G

O

E

W2

E

W3

R

Y

24 VAC COM

HEAT STAGE 2

COOL/HEAT

STAGE 1

INDOOR FAN

EMERGENCY

HEAT

O

*

*

*

IF AVAILABLE

*

LEGEND

24-V FACTORY WIRING

24-V FIELD WIRING

FIELD SPLICE CONNECTION

OUTDOOR THERMOSTAT

EMERGENCY HEAT RELAY

SUPPLEMENTAL HEAT RELAY

SHR

EHR

ODT

A02325 / A97413

Fig. 8 -- Generic Wiring Diagrams

(See Thermostat Installation Instructions

for specific unit combinations)

Sequence of

Operation

NOTE: Defrost control board is equipped with 5 minute lockout

timer that is initiated upon any interruption of power.

Turn on power to indoor and outdoor units. Transformer is

energized.

Cooling

On a call for cooling, thermostat makes circuits R--O, R--Y, and

R --G . Circuit R --O energizes reversin g valve, switchi n g it to

cooling position. Circuit R--Y sends low voltage through the

safeties and energizes the T1 terminal on the circuit board. If the

compressor has been off for 5 minutes, or power has not been

cycled for 5 minutes, the OF2 relay and T2 t erminal will energize.

This will close the contactor, and start the outdoor fan motor and

compressor.

When the cycle is complete, R-- Y is turned off, stopping the

compressor and outdoor fan. The 5 minute time guard begins

counting. Compressor will not come on again until this delay

expires. In the event of a power interruption, the time guard will

not allow another cycle for 5 minutes.

NOTE: If the indoor blower off delay is enabled, it will run up to

an additional 90 seconds to increase system efficiency.

Heating

On a call for heating, thermostat makes circuits R--Y and R--G.

Circuit R--Y sends low voltage through the safeties and energizes

the T1 terminal on the circuit board. T1 energizes the defrost logic

circuit. If the compressor has been off for 5 minutes, or power

has not been cycled for 5 minutes, the OF2 relay and T2 terminal

will energize. This will close the contactor, start the outdoor fan

motor and compressor.

When the cycle is complete, R-- Y is turned off , stopping the

compressor and outdoor fan. The 5 minute time guard begins

counting. Compressor will not come on again until this time delay

expires. In the event of a power interruption, the time guard will

not allow another cycle for 5 minutes.

25HCS