20

delicate and should protected from dirt and

abuse. Nozzles are mass produced and can vary

from sample to sample. For all of those reasons

a spare nozzle is a desirable item for a service-

man to carry.

b. FLAME SHAPE — Looking into the combus-

tion chamber through the flame plug hole, the

flame should appear straight with no sparklers

rolling up toward the top of the chamber. If the

flame drags to the right or left, sends sparklers

upward or makes wet spots on the combustion

chamber, the nozzle should be replaced. If the

condition persists look for fuel leaks, air leaks,

water or dirt in the fuel as described below.

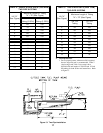

Figure 14: Electrode / Head Setting

c. FUEL LEAKS— Any fuel leak between the pump

and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in the

air tube, under the ignitor, and around the air

inlet. Any such leaks should be repaired as they

may cause erratic burning of the fuel and in the

extreme case may become a fire hazard.

d. AIR LEAKS— Any such leaks should be

repaired, as they may cause erratic burning of

the fuel and in extreme cases may become a fire

hazard.

There may be many possible causes of leaks in

oil lines such as:

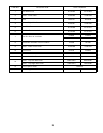

See Manila folder in file titled “HF”