32

instrumentation to obtain a CO

2

of 11.5 to 12.5%

with draft of -.02” w.c. in fire box. These settings

will assure a safe and efficient operating condition.

If the flame appears stringy instead of a solid flame,

try another nozzle of the same type. Flame should

be solid and compact. After all adjustments have

been made, recheck for a draft of -.02” w.c. over the

fire.

4. TURN “OFF” BURNER and remove pressure

gauge. Install gauge port plug and tighten. Start

burner again.

M. FLAME FAILURE

The RSA boiler controls operate the burner automati-

cally. If for unknown reasons the burner ceases to fire

and the rest button on the primary control has tripped,

the burner has experienced ignition failure. Before

pressing the rest button, call your serviceman immedi-

ately.

N. CHECK FOR CLEAN CUT OFF OF BURNER

1. AIR IN THE OIL LINE between fuel unit and

nozzle will compress when burner is on and will

expand when burner stops, causing oil to squirt

from nozzle at low pressure as burner slows down

and causing nozzle to drip after burner stops.

Usually cycling the burner operation about 5 to 10

times will rid oil line of this air.

2. IF NOZZLE CONTINUES TO DRIP, repeat step

N.1. If this does not stop the dripping, remove cut

off valve and seat, and wipe both with a clean cloth

until clean. Then replace and readjust oil pressure.

If dripping or after burn persist replace fuel pump.

O. HINTS ON COMBUSTION

a. NOZZLES— Although the nozzle is a relatively

inexpensive device, its function is critical to the

successful operation of the oil burner. The

selection of the nozzle supplied with the RSA

boiler is the result of extensive testing to obtain

the best flame shape and efficient combustion.

Other brands of the same spray angle and spray

pattern may be used but may not perform at the

expected level of CO

2

and smoke. Nozzles are

delicate and should protected from dirt and

abuse. Nozzles are mass produced and can vary

from sample to sample. For all of those reasons

a spare nozzle is a desirable item for a service-

man to carry.

b. FLAME SHAPE — Looking into the combus-

tion chamber through the flame plug hole, the

flame should appear straight with no sparklers

rolling up toward the top of the chamber. If the

flame drags to the right or left, sends sparklers

upward or makes wet spots on the combustion

chamber, the nozzle should be replaced. If the

condition persists look for fuel leaks, air leaks,

water or dirt in the fuel as described below.

c. FUEL LEAKS— Any fuel leak between the

pump and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in the

air tube, under the ignitor, and around the air

inlet. Any such leaks should be repaired as they

may cause erratic burning of the fuel and in the

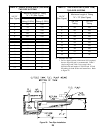

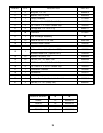

Figure 23: Electrode / Head Setting

(Non-Burnham Drawing

Copy from other Manual)