31

SOLID stream without air bubbles for approxi-

mately 10 seconds.

3. Close vent fitting and burner flame should start

immediately.

4. If the burner does not start immediately, check the

manual overload switch on the motor, if so

equipped, and the safety switch on the burner

primary control.

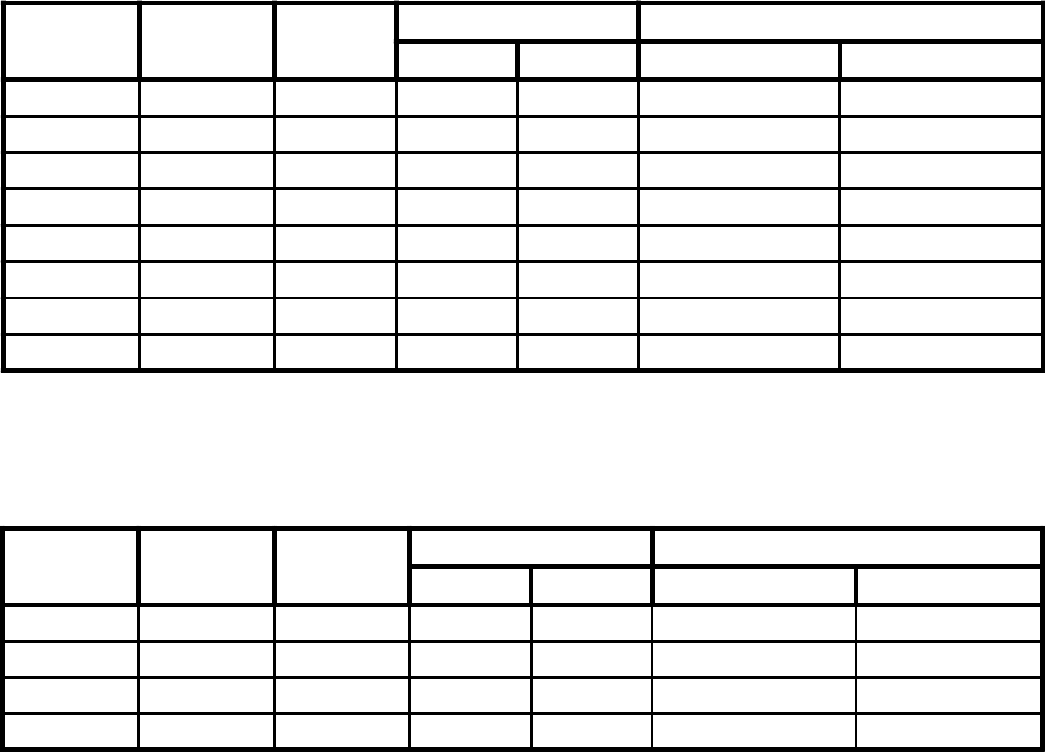

K. ADJUST OIL PRESSURE

1. Locate oil pressure adjusting screw and turn

screw until Pressure Gauge reads the correct

pump pressure required for the specific boiler.

Refer to table 4 & 4A.

2. DO NOT REMOVE PRESSURE GAUGE until

later.

L. OTHER ADJUSTMENTS

1. ADJUST THE AIR BAND AND/OR AIR SHUT-

TER.

Beckett Burners:

a. Adjust air supply by loosening lock screws and

moving the air shutter and if necessary the air

band. Refer to Table 4 and 4A preliminary

settings.

2. ADJUST DRAFT REGULATOR for a draft of

-.02” (water gauge) over the fire after chimney has

reached operating temperature and while burner is

running.

3. READJUST AIR BANDS on burner for a light

orange colored flame while draft over the fire is

-.02” w.c. Use a smoke test and adjust air for

minimum smoke (not to exceed #1) with a mini-

mum of excess air. Make final check using suitable

Table 4A: Becket AFG Burner

Table 4: Beckett AFG, AF, & SF Burners

Boiler Model

Firing Rate

(GPH)

Hago

Nozzle

Air Settings

Shutter Band Head (stop screw) Pump Pressure

RSAH85 .75 .65 x 80B 6 0 N/A 140

RSAH110 1.0 .85 x 80B 7 0 N/A 140

RSAH125 1.1 .90 x 80B 7 0 N/A 140

RSAH135 1.25 1.0 x 80B 9 0 N/A 140

Boiler Model

Firing Rate

(GPH)

Hago

Nozzle

Air Settings

Shutter Band Head (stop screw) Pump Pressure

RSA85 .85 .75 x 70B 10 0 N/A 140

RSA110 1.10 .90 x 80B 8 0 N/A 140

RSA125 1.25 1.0 x 80B 7 0 N/A 140

RSA135 1.35 1.10 x 80B 9 0 N/A 140

RSA170 1.70 1.65 80 A 7 0 N/A 100

RSA195 1.95 2.00 80 B 7 0 N/A 100

RSA240 2.40 2.50 80 B 7 0 N/A 100

RSA285 2.85 3.00 80 B 7 0 N/A 100