T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

60-2485—826

Defrost Control

In some re

g

ions, durin

g

half or more of the heatin

g

season,

the outdoor coil operates below 32°F

(

0°C

)

Frost or ice builds

up on the outdoor coil of a heat pump similarl

y

to the frost

buildup in a household refri

g

erator. Eventuall

y

, this

accumulation of ice interferes with efficient heat transfer from

the outdoor air to the coil and refri

g

erant. Defrostin

g

is

occasionall

y

re

q

uired to remove this ice, and restore the heat

pump abilit

y

to absorb heat from the air.

Defrosting

A heat pump defrosts its outdoor coil b

y

temporaril

y

switchin

g

to the coolin

g

mode, which causes hot

g

as from the

compressor to be directed to the outdoor coil instead of to the

indoor coil so the heat pump is takin

g

heat from the home to

warm up the outdoor coil. Defrostin

g

is the

g

reatest detriment

to heat pump efficienc

y

.

Defrost Control Functions

Besides chan

g

in

g

over to the coolin

g

mode, defrostin

g

re

q

uires several more control initiated actions that follow.

OUTDOOR FAN

When defrostin

g

has be

g

un, it is standard practice to turn off

the outdoor fan to speed up the meltin

g

process. A separate

defrost rela

y

is re

q

uired to control that fan. See Fi

g

. 37. Other

contacts can be needed on the defrost rela

y

to power the

chan

g

eover valve or power part of the auxiliar

y

heat.

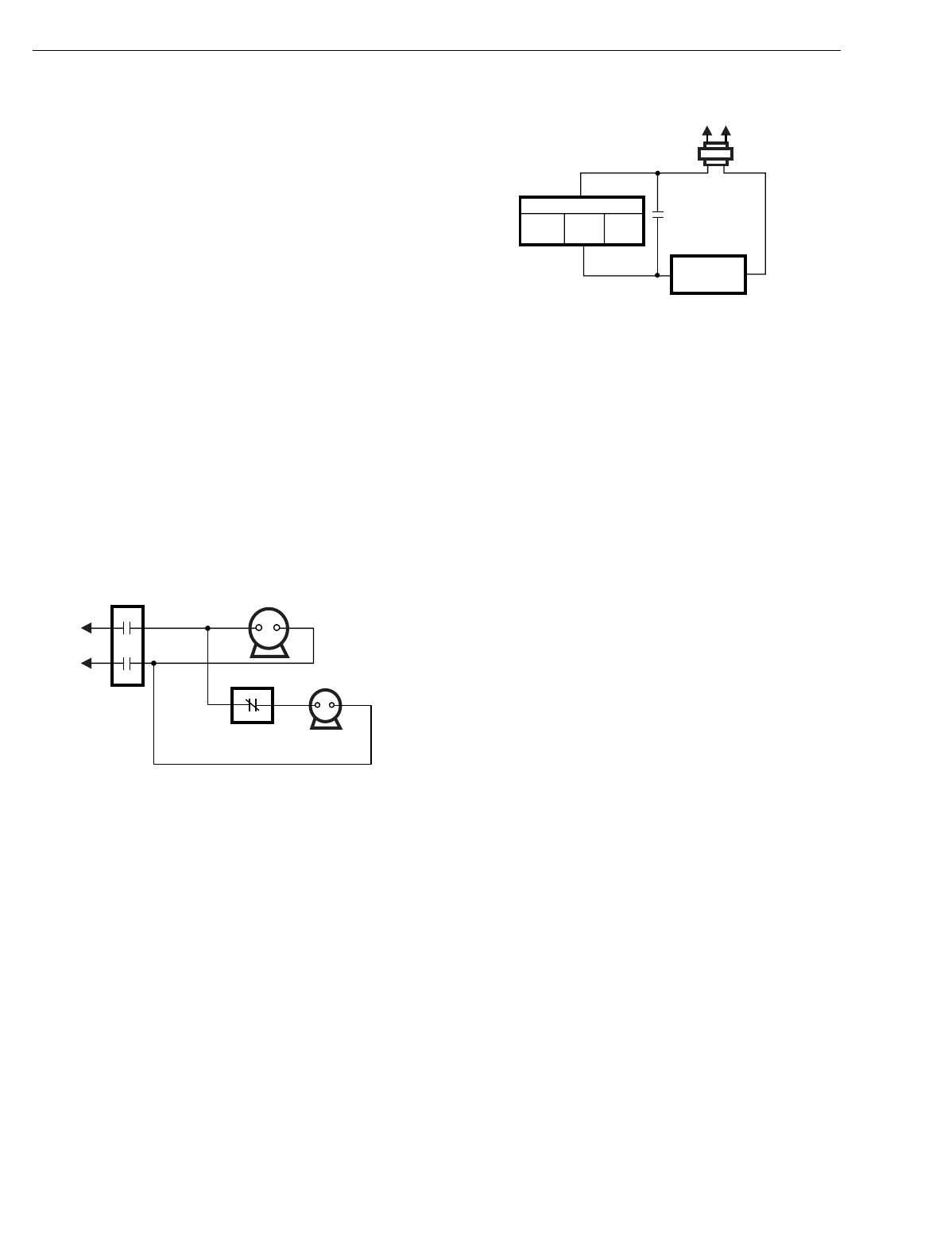

Fig. 37. Outdoor fan with defrost control.

AUXILIARY HEAT DURING DEFROST

Most pump manufacturers brin

g

on some auxiliar

y

heat durin

g

defrost, althou

g

h this is not a universal practice. Some rel

y

on

the second sta

g

e of the thermostat to call for auxiliar

y

heat as

needed. Since the heat pump is operatin

g

in the coolin

g

mode

to defrost, it is deliverin

g

cold air to the livin

g

space. Auxiliar

y

heat is used to offset this coolin

g

. It re

q

uires another normall

y

open contact on the defrost rela

y

. See Fi

g

. 38.

Fig. 38. Auxiliary heat with defrost control.

WHEN TO DEFROST

Timel

y

defrostin

g

is an essential component of effective heat

pump operation. Failure to defrost often enou

g

h permits too

much ice to accumulate on the coil. At the ver

y

least, this

hurts efficienc

y

; at worst, it results in compressor dama

g

e.

Insufficient defrostin

g

is a condition the heat pump

manufacturer wants ver

y

much to avoid.

A 50 percent reduction in outdoor airflow is the maximum that

would be tolerated. So the desi

g

ner of a heat pump would

select a control point that puts the s

y

stem into defrost when

airflow throu

g

h the outdoor coil approaches half its normal

level. Restricted airflow causes a

g

reater load on the

compressor; the outdoor coil runs colder, suction pressure is

lower and the motor runs hotter.

At the other end of the scale, defrostin

g

too often hurts the

overall ener

gy

efficienc

y

of the s

y

stem. Consider that in terms

of heatin

g

the buildin

g

, defrostin

g

is a bi

g

loss. Not onl

y

does

the s

y

stem stop heatin

g

, but it actuall

y

moves heat out of the

buildin

g

. If electric strip heat is used, it is a further waste

because its COP is 1.0 and not the 2.0 or more COP realized

if the heat is provided b

y

the heat pump.

So, concern for e

quipment safety

su

gg

ests fairl

y

fre

q

uent

defrostin

g

while

economy of operation

ar

g

ues for fewer

defrost c

y

cles. Since the e

q

uipment manufacturer chooses, the

balance is usuall

y

tipped in favor of more fre

q

uent defrostin

g

to

avoid the possibilit

y

of dama

g

in

g

the compressor.

Auxiliary Heat

Except in warm climates, all air-to-air heat pump installations

re

q

uire auxiliar

y

heat capabilit

y

. Electric resistance heaters

can provide this auxiliar

y

heat.

The electric heaters

(

sometimes called strip heaters

)

usuall

y

are supplied in 5 kW units or strips

(

about 17,000 Btu

)

. The

indoor unit of the heat pump is desi

g

ned to accommodate

various electric heat units so it can be used in variousl

y

sized

buildin

g

s in different parts of the countr

y

.

Two-Stage Thermostat

The most common heat pump control strate

gy

is for the

thermostat first sta

g

e to switch the compressor and the

second sta

g

e to switch the auxiliar

y

heat. See Fi

g

. 39.

M5839

COMPRESSOR

MOTOR

CONTACTOR

CONTROLLED BY

DEFROST RELAY

OUTDOOR

FAN MOTOR

M5835

THERMOSTAT

HEAT 2

HEAT 1

DEFROST

RELAY

CONTACT

AUXILIARY

HEAT RELAY

L1

(HOT)

L2

TRANSFORMER