WARNING: Before performing service or maintenance

operations on system, turn off main power to unit and

install lock-out tag. Turn off accessory heater power

switch if applicable. Electrical shock could cause severe

injury or death.

CAUTION: Puron® (R-410A) systems operate at higher

pressures than standard R-22 systems. Do not use R-22

service equipment or components on Puron® (R-410A)

equipment. Ensure service equipment is rated for Puron®

(R-410A)

INTRODUCTION

NOTE: The minimum outdoor cooling operating temperature for

units using this ICM motor option is 55°F. To operate in cooling

at lower ambients the Motor Master™ II low ambient kit is

required.

These instructions cover the installation of a Bryant Small Pack-

aged Product with ICM motor-factory installed option (FIOP).

This option can be selected as a FIOP on gas heating/electric

cooling (583B), dual fuel–electric heat pump with gas heat

back-up (683B), electric cooling (702B) or electric heat pump

(602B) units with Puron®.

RECEIVING AND INSTALLATION

Refer to unit Installation Instructions.

ICM FIOP PRE-START-UP

I. ELECTRICAL CONNECTIONS

A. Control Voltage Connections

NOTE: Do not use any type of power-stealing thermostat, with-

out connecting the C (Common) terminal. Failure to follow this

note could result in unit control problems.

Use no. 18 American Wire Gage (AWG) color-coded, insulated

(35 C minimum) wires to make the control voltage connections

between the thermostat and the unit. If the thermostat is located

more than 100 ft from the unit (as measured along the control

voltage wires), use no. 16 AWG color-coded, insulated (35 C

minimum) wires.

B. Standard Connection

Remove knockout hole located in the heat section panel adjacent to

the service access panel (See unit installation package). Remove

the rubber grommet from the installer’s packet (included with unit)

and install grommet in the knockout opening. Provide a drip loop

before running wire through panel. Run the low-voltage leads from

the thermostat, through the inlet hole, and into unit low-voltage

splice box. Locate 18-gage wires leaving control box. These

low-voltage connection leads can be identified by colors (See Fig.

2, 3, 4 or 5). Ensure the leads are long enough to be routed into the

low-voltage splice box (located below right side of control box).

Route leads through hole in bottom of control box and make

low-voltage connections (See Fig. 2, 3, 4 or 5). Secure all cut

wires, so that they do not interfere with operation of unit.

SPECIAL PROCEDURES FOR 208–V OPERATION

WARNING: Make sure that the power supply to the unit

is switched OFF before making any wiring changes. With

disconnect switch open, move yellow wire from trans-

former (3/16 in.) terminal marked 230 to terminal marked

200. This retaps transformer to primary voltage of 208-v.

Electrical shock could cause serious injury or death.

C. Easy Select™—583B

EASY SELECT™ CONFIGURATION TAPS FOR 583B

Easy Select™ taps are used by the installer to configure a system.

The ICM motor uses the selected taps to modify its operation to a

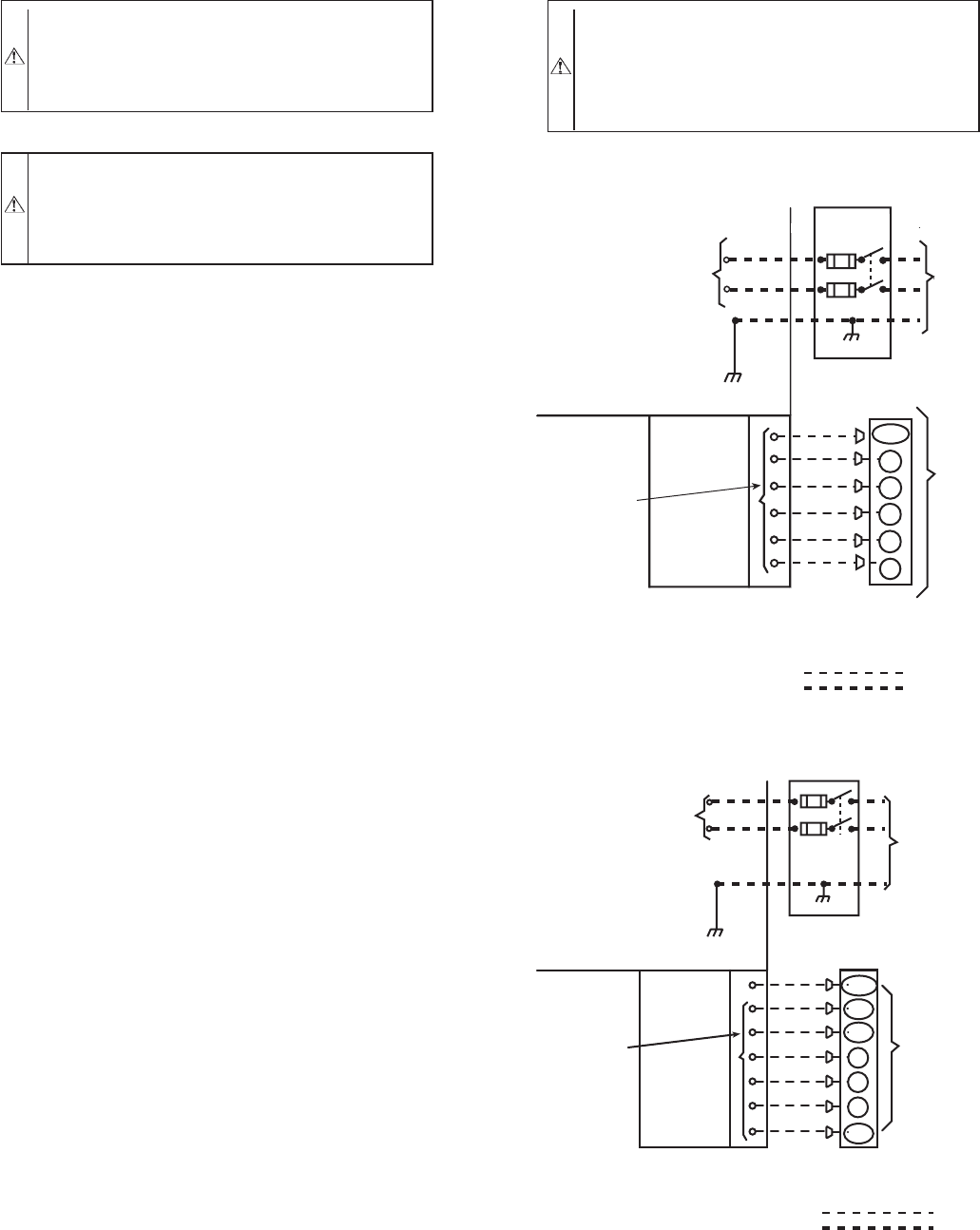

Fig. 2—583B High- and Control-Voltage

Connections

C01026

POWER

SUPPLY

FIELD-SUPPLIED

FUSED DISCONNECT

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

GND

CONTROL BOX

SPLICE BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

YEL(Y)

GRN(G)

RED(R)

BRN(C)

THERMOSTAT

(TYPICAL)

LEGEND

Field Control-Voltage Wiring

Field High-Voltage Wiring

BLK(DH)

DHUM

Y

G

R

C

W1

WHI(W1)

Fig. 3—683B High- and Control-Voltage

Connections

C01107

POWER

SUPPLY

FIELD-SUPPLIED

FUSED DISCONNECT

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

GND

CONTROL BOX

SPLICE BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

THERMOSTAT

(THERMIDISTAT ™ )

G

R

C

YEL(Y)

GRN(G)

RED(R)

BRN(C)

ORN(O)

W/W1

WHT(W1)

DHUM

BLK (DH)

FIELD CONTROL - VOLTAGE WIRING

FIELD HIGH - VOLTAGE WIRING

Y/Y2

O/W2

—2—