blower motor stops. The unit is in a ‘‘standby’’ condition, waiting

for the next ‘‘call for cooling’’ from the room thermostat. The 5

minute compressor delay also applies to heat pump heating mode.

ELECTRICAL DATA & SCHEMATICS—ICM FIOP

I. PHYSICAL DATA & ELECTRICAL SCHEMATICS

Use the Physical Data and Electrical Tables on the following pages

for information that applies to Bryant Puron® units with the ICM

indoor motor FIOP.

AIRFLOW & TEMPERATURE RISE TABLES—ICM

FIOP

II. TABLES FOR SYSTEM SET-UP

Use the Airflow and Temperature Rise Tables on the following

pages for information that applies to Bryant Puron® units with the

ICM indoor motor FIOP.

CARE AND MAINTENANCE

Indoor Blower and Motor

NOTE: All motors are pre-lubricated. Do not attempt to lubricate

these motors. For longer life, operating economy, and continuing

efficiency, clean accumulated dirt and grease from the blower

wheel and motor annually.

WARNING: Disconnect and tag electrical power to the

unit before cleaning and lubricating any blower motor

and wheel. On units with gas heat, turn off the gas supply

before disconnecting the electrical power. Failure to

adhere to this warning could cause serious injury or

death.

To clean the blower motor and wheel:

1. 1. Remove and disassemble blower assembly as follows:

a. Remove unit access panel.

b. Carefully pivot blower access panel outward towards the

electrical box. Route wiring above blower access panel.

c. Disconnect the 5 and 16 pin plugs at the blower motor.

d. On all units, remove blower assembly from unit. Re-

move screws securing blower to vertical partition and

slide assembly out. Be careful not to tear insulation in

blower compartment.

e. Ensure proper reassembly by marking blower wheel and

motor in relation to blower housing before disassembly.

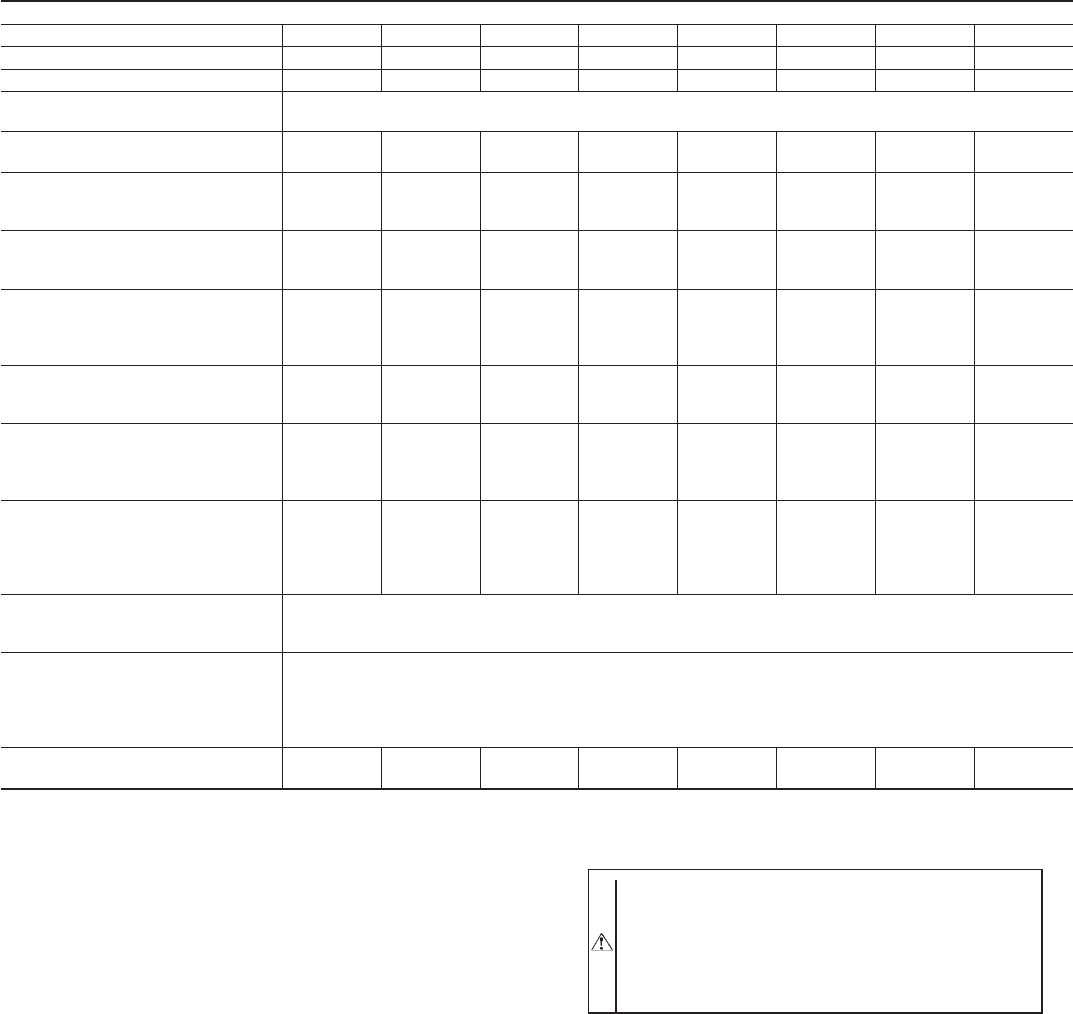

TABLE 1—ICM FIOP PHYSICAL DATA—UNIT 583B

THIS DATA APPLIES TO 583B UNITS WITH THE ICM INDOOR MOTOR FIOP

UNIT SIZE 583B 024040 024060 030040 030060 036060 036090 042060 042090

NOMINAL CAPACITY (ton) 2 2 2-1/2 2-1/2 3 3 3-1/2 3-1/2

OPERATING WEIGHT (lb.) 290 290 313 313 321 321 382 382

COMPRESSORS

Quantity

Scroll

1

REFRIGERANT (R-410A)

Quantity (lb.)

5.0 5.0 5.5 5.5 6.9 6.9 9.0 9.0

REFRIGERANT METERING DEVICE

Orifice ID (in.)

Check-Flo-Rater™ Piston

.057 .057 .057 .057 .065 .065 .070 .070

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

1...17

10.9

1...17

10.9

1...17

12.7

1...17

12.7

2...17

9.1

2...17

9.1

2...17

12.3

2...17

12.3

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor HP (Rpm)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

3...15

3.7

3...15

3.7

3...15

3.7

3...15

3.7

3...15

3.7

3...15

3.7

3...15

4.7

3...15

4.7

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor (HP)

800

10X10

1/2

800

10X10

1/2

1000

10X10

1/2

1000

10X10

1/2

1200

11X10

3/4

1200

11X10

3/4

1400

11X10

3/4

1400

11X10

3/4

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

Burner Orifice No. (Qty...Drill Size)

Propane Gas

2...44

2...50

2...38

2...46

2...44

2...50

2...38

2...46

2...38

2...46

3...38

3...46

2...38

2...46

3...38

3...46

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto)

610±15

420±25

LOSS-OF-CHARGE/LOW-

PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto)

20±5

45±10

RETURN-AIR FILTERS (in.)

Throwaway

20X20X1 20X20X1 20X20X1 20X20X1 20X24X1 20X24X1 24X30X1 24X30X1

* Based on altitude of 0 to 2000 ft.

—12—