16

completes the control circuit. The direct--spark ignition system

cycles and the unit returns to normal heating operation.

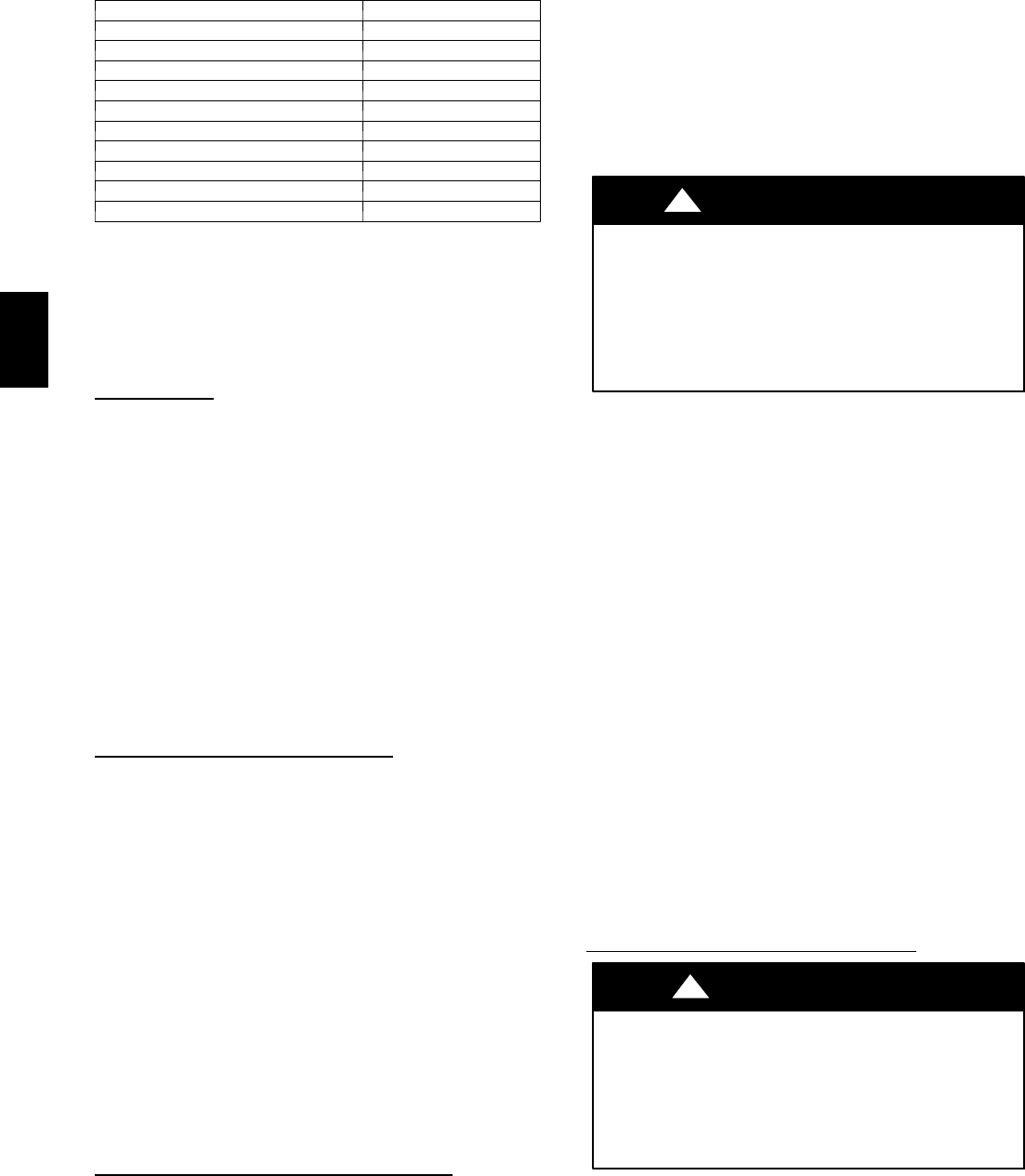

Table 5 – LED Indications

STATUS CODE LED INDICATION

Normal Operation

2

On

No Power Hardware Failure Off

Limit Switch Fault 2 F lashes

Flame Sense Fault 3 F lashes

Four Consecutive Limit Switch Faults 4 F lashes

Ignition Lockout Fault 5 Flashes

Pressure Switch Fault 6 Flashes

Rollout Switch Fault 7 F lashes

Internal Control Fault 8 Flashes

Temporary 1 hr auto reset

1

9 F lashes

NOTES:

1.Th is code indicates an i nternal processor fau lt that will r eset itself in one

hr. Fault can be caused by stray RF signals in the structure or nearby. This

is a UL requirement.

2. LED indicates acceptable operation. Do not change ignition control

board.

3. When W is energized the burners will remain on for a minimum of 60 sec.

4.IfmorethanoneerrormodeexiststheywillbedisplayedontheLEDin

sequence.

Rollout Switch

The function of th e rollout switch is to close the main gas valve in

the event of flame rollout. The switch is located above the main

bur ners. When the temperatur e at the rollout switch reaches the

maximum allowable temperature, th e con trol circuit trips, clos ing

the gas valve and stopping gas flow to the burners. The indoor

(evaporator) fan motor (IFM) and induced draft motor continue to

run until switch i s r eset. The IGC LED will display FAULT CODE

7.

Step 4 — Start--up Cooling and Make Adjust-

ments

Complete the required procedures given in the Pre--Start--Up

section before starting the unit. Do not jumper any safety devices

when operating the unit. Do not operate the compressor when the

outdoor temperature is below 40°F(4.4°C) (unless accessory

low--ambient kit is installed). Do not rapid--cycle the compressor.

Allow 5 minutes between on cycles to prevent compressor damage.

Checking Cooling Control Operation

Start and check the unit for proper cooling control operation as

follows:

1. Place room thermostat SYSTEM switch in OFF position.

Observe that blower motor starts wh en FAN switch is

placed in ON position and shuts down when FAN switch is

placed in AU T O position.

2. Place SY STEM switch in COOL position and FAN switch

in AUTO position. Set cooling control below room

temperature. Observe that compressor, condenser fan, and

evaporator blower motors start. Observe that cooling cycle

shut s down when con trol setting is satisfied. The evaporator

fan will continue to run for 90 sec.

IMPORTANT: Three--phase, scroll compressors units are

direction oriented. Unit must be checked to ensure proper

compressor 3-- phase power lead orientation. If not corrected within

5 minutes, the internal protector will shut off the compressor. The

3--phase power leads to the unit must be reversed to correct

rotation. When turning backwards, the difference between

compressor suction and discharge pressures will be near zero.

Checking and Adjusting Refrigerant Charge

The refrigerant system is fully charged with PuronR (R --410A)

refrigerant and is tested and factory sealed. Allow system to operate

a minimum of 15 minutes before checking or adjusting charge.

NOTE: Adjustment of the refrigerant charge is not required unless

the unit is suspected of not having the proper PuronR (R--410A)

charge.

The c harging label and the tables show n refer to system

temperatures and pressures in cooling mode only. A refrigerant

charging label is attached to the inside of the compressor access

panel. The chart includes the required liquid line temperature at

given discharge line pressures and outdoor ambient temperatures.

An accurate therm ocouple-- or thermistor-- type thermometer, and a

gauge manifold are required when using the subcooling charging

method for evaluating the unit charge. Do not use mercury or small

dial--type thermometers because they are no t adequate for this type

of measu rement.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

When evaluating t he refrigerant ch arge, an indicated

adjustment to the specified factory char ge must always be

very minimal. If a substantial adjustment is indicated, an

abnormal condition exists s omewhere in the cooling system,

such as insufficient airflow across either coil or both coils.

!

CAUTION

Proceed as follows:

1. Remove caps from low-- and high--p ressure service fittings.

2. Using hoses with valve core depresso rs, attach low-- a nd

high--pressure gauge hoses to low-- and high--pressure

service fittings , r espectively.

3. Start unit in Cooling Mode and let unit run until system

pressures stabilize.

4. Measure and record the following:

a. Outdoor ambient-- air temperature (°F(°C) db).

b. Liquid line temperature (°F(°C).

c. Discharge (high--side) pressure (psig).

d. Suction (low--side) pressure (psig) (for reference only).

5. Using “Cooling Charging Charts,” compare outdoor--air

temperature(°F(°C) db) with the discharge line pressure

(psig) to determine desired system operating liquid line

temperature (See Fig. 17).

6. Compare actual liquid line temperature with desired liquid

line tem perature. Using a tol erance of ± 2°F(±1.1°C), add

refrigerant if actual tempe rature is more than 2°F(1.1°C)

higher than proper liquid line temperature, or remove

refrigerant if actual temperature is more than 2°F(1.1°C)

lower than required liquid line temperature.

NOTE: If the probl em causing the inaccurate readin gs is a

refrigerant leak, refer to the Check for Refrigerant Leaks section.

Indoor Airflow and Airflow Adjustments

UNIT OPERATION HAZARD

Failure to follow this cautio n may result in unit damage.

For cooling operation, the recommended airflow is 350 to

450 cfm for each 12,000 Btuh of rated cooling capacity. For

heating operation, the airflow must produce a temperature

rise that falls within the range stamped on the un it rating

plate.

CAUTION

!

NOTE: Be sure that all supply--and return --air grilles are open,

free from obstructions, and adjusted properly.

677C-- --A