39

85

(29)

90

(32)

95

(25)

100

(38)

105

(41)

110

(43)

80

(27)

75

(24)

70

(21)

65

(18)

60

(16)

55

(13)

50

(10)

45

(7)

40

(4)

35

(2)

A

B

B

C

C

D

D

35

(2)

40

(4)

45

(7)

50

(10)

55

(13)

60

(16)

65

(18)

70

(21)

75

(24)

80

(27)

85

(29)

90

(32)

95

(36)

100

(38)

105

(41)

110

(43)

A

APPROXIMATE DRY BULB TEMPERATURE — ˚F (˚C)

ENTHALPY – BTU PER POUND DRY AIR

12

14

16

18

20

22

24

26

28

30

100

90

80

70

60

50

40

32

34

36

38

40

42

44

46

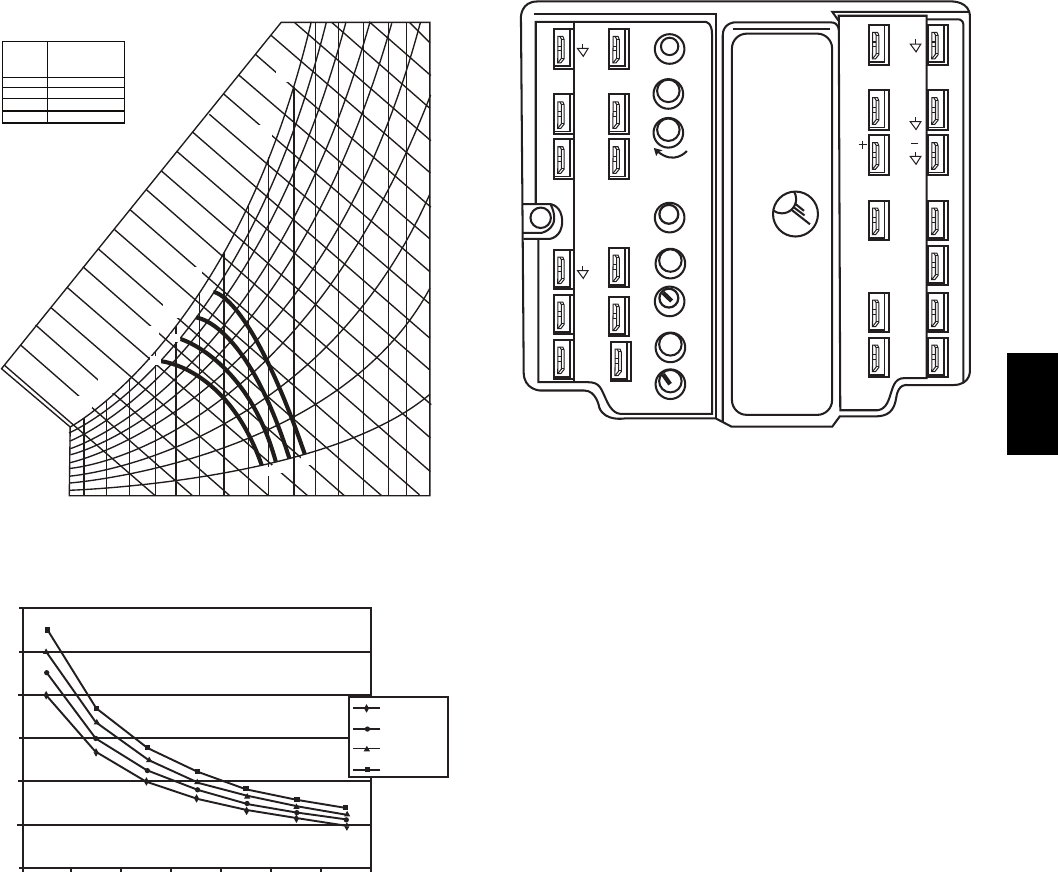

CONTROL

CURVE

CONTROL POINT

APPROX ˚F (˚C)

AT 50% RH

A 73 (23)

67 (19)

63 (17)

70 (21)

B

C

D

30

20

10

RELATIVE HUMIDITY (%)

A09711

Fig. 42 -- Enthalpy Changeover Setpoints

6000

5000

4000

3000

2000

1000

0

2345678

800 ppm

900 ppm

1000 ppm

1100 ppm

A09713

Fig. 43 -- CO

2

Sensor Maximum Range Setting

OUTDOOR ENTHALPY CHANGEOVER—For enthalpy

cont rol, accessory enthalpy sens or (part number HH57AC 078) is

required. Replace the standard outdoor dry bulb temperature sensor

with the accessory enthalpy sensor in the same m ounting location.

When the outdoor air enthalpy rises above the outdoor enthalpy

changeover set point, the outdoor--air damper moves to its

minimum position. The outdoor enthalpy changeover set point is

set with the outdoor enthalpy set point potentiometer on the

Economizer controller. The set points are A, B, C, and D. See Fig.

42. The factory--installed 620 --ohm jumper must be in place across

terminals SR and SR+ on the Economizer controller. See Fig. 44

and Fig. 45.

TR TR1

24

Vac

HOT

24 Vac

COM

12

5

43

EF1EF

C

10V

DCV

DCV

Max

DCV

DA

B

Set

2V

10V

10V

Min

Pos

2V

2V

Free

Cool

SR

SO

SO+

AQ+

T1

T

P

P1

N1

N

AQ

SR+

Open

EXH

Set

EXH

A09712

Fig. 44 -- Economizer Controller

DIFFERENTIAL ENTHALPY CONTROL — For differential

enthalpy control, the Economizer controller uses two enthalpy

sensors (HH57AC078 and CRENTDIF004A00), one in the outside

air and one in the return airstream. The Economizer controller

compares the outdoor air enthalpy to the return air enthalpy to

determine Economizeruse. Thecontroller selectsthe lowerenthalpy

air(returnoroutdoor)forcooling.Forexample, when the outdoorair

hasalowerenthalpy than the return airand isbelow theset point,the

Economizeropenstobringinoutdoorairforfreecooling.Replacethe

standard outside air dry bulb temperature sensor with the accessory

enthalpy sensor in the same mounting location. Mountthe return air

enthalpy sensor in the return air duct. See Fig. 41. When using this

mode of changeover control, turn the enthalpy set point poten-

tiometer fully clockwise to t he D setting.

INDOOR AIR QUALITY (IAQ) SENSOR INPUT —The IAQ

inputcan beusedfordemandcontrolventilation controlbased on the

level of CO

2

measured in the space or return air duct. Mount the

accessory IAQ sensor according to manufacturer specifications. The

IAQ sensor should be wired to the AQ and AQ1 terminals of the

controller.AdjusttheDCVpotentiometersto correspondtotheDCV

voltage output of the indoor air quality sensor at the userdeterm ined

set point.SeeFig.43. If aseparate field--supplied transformer isused

to power the IAQ sensor, the sensor must not be grounded or the

Economizer control board will be damaged.

EXHAUST SET POINT ADJUSTMENT—Theexhaust setpoint

will determine when the exhaust fan runs based on dampe r po sition

(if power exhaust is installed). The set point is modified with the

Exhaust Fan Set Point (EXH SET) potentiometer. See Fig. 45 for

Wiring Diagram. The set pointrepresentsthedamper pos ition above

which the exhaust fans will be turned on. When there is a call for

exhaust,theEconomizer controller providesa45 ± 15second delay

beforeexhaustfanactivation toallowthedamperstoopen.Thisdelay

allows the damper to reach the app ropriate position to a void

unnecessary fan overload.

MINIMUM POSITION CONTROL — There is a minimum

damper position potentiometer on the Economizer controller. See

Fig. 39 and 45. The minimum damper position maintains the

minimumairflowintothebuildingduringtheoccupiedperiod.When

using demand ventilation, the minim um damper position represents

the minimum ventilation position for VOC (vo latile organic

compound) ventilation requirements. The DCV Max potentiometer

must be fully clos ed (CCW) to allow the Minimum Position

pot entiometer t o function correctly.

607C-- --A