151

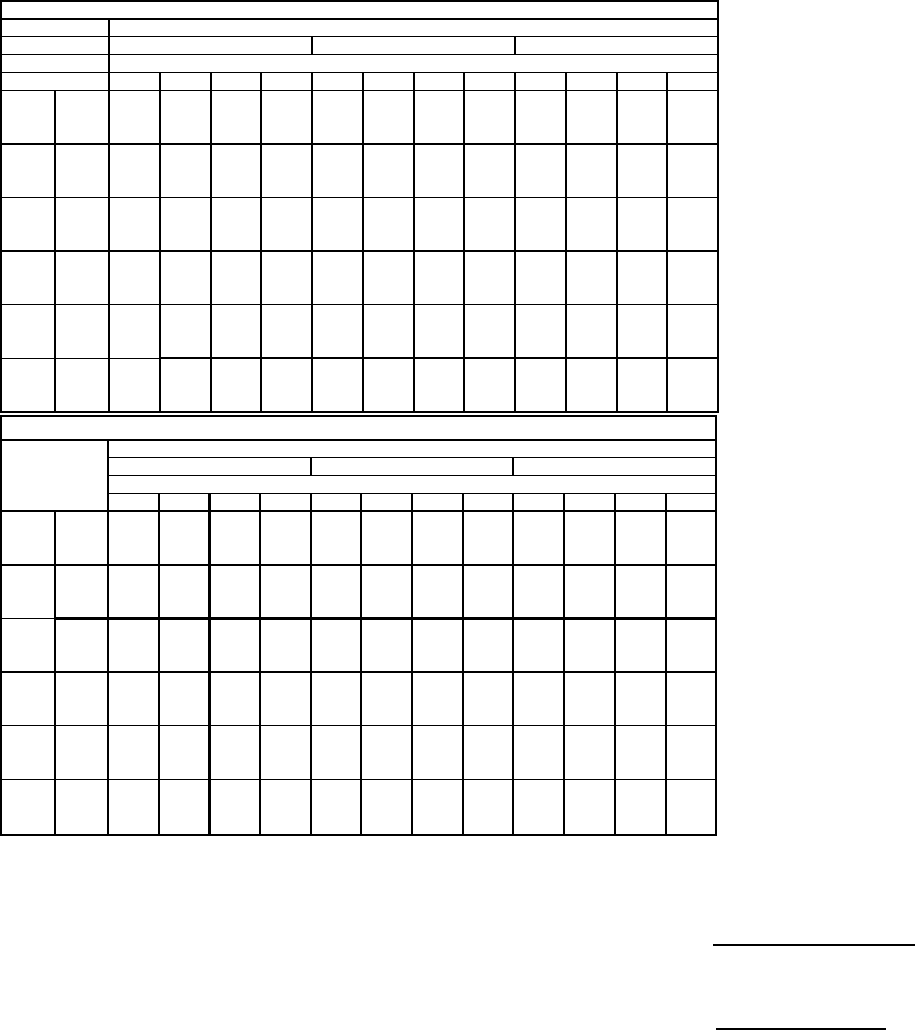

PERFORMANCE DATA — 581C

COOLING CAPACITIES — 581C024-060 STANDARD UNITS

581C024 (2 Tons)

Temp (F) Air Entering Evaporator -- CFM/BF

Air Ent 600/0.12 800/0.14 1000/0.18

Condenser Air Entering Evaporator -- Ewb (F)

(Edb) 576267725762677257626772

75

TCG 22.6 24.3 26.7 29 25 25.7 28.1 30.2 26.6 26.8 29 30.9

SHG 21.7 19.5 16.4 13 24 22.9 18.6 14.1 25.6 25.4 20.6 15.1

CMP 1.18 1.19 1.2 1.21 1.19 1.19 1.2 1.21 1.19 1.2 1.21 1.22

85

TCG 21.3 23 25.7 28 24.2 24.7 27.2 29.6 25.9 25.9 27.9 30.2

SHG 20.5 19 16 12.7 23.3 22.4 18.4 14.1 24.9 24.9 20.3 15.1

CMP 1.36 1.37 1.38 1.39 1.38 1.38 1.39 1.4 1.38 1.38 1.39 1.4

95

TCG 19.9 21 24.7 27.2 23.1 23.3 26 28.6 25 24.9 26.9 29.3

SHG 19.1 18.2 15.7 12.4 22.2 21.9 18.1 13.9 24 24 20.2 15.1

CMP 1.56 1.57 1.59 1.6 1.58 1.58 1.59 1.61 1.59 1.59 1.6 1.61

105

TCG 18.4 18.8 23.2 26 21.3 21.3 24.8 27.4 23.9 23.9 25.6 28.2

SHG 17.7 17.3 15.1 12 20.5 20.5 17.7 13.5 23 23 19.9 14.8

CMP 1.78 1.78 1.81 1.82 1.8 1.8 1.82 1.83 1.81 1.81 1.82 1.84

115

TCG 16.6 16.5 20.5 24.7 19.7 19.7 22.4 26 22 22 24.1 26.7

SHG 16 15.9 14.1 11.6 19 19 16.9 13.1 21.1 21.1 19.5 14.5

CMP 2.01 2.01 2.05 2.08 2.05 2.05 2.06 2.08 2.06 2.06 2.07 2.09

125

TCG 15 15 17.7 22.2 17.7 17.7 19.6 24.4 19.7 19.8 20.5 25.2

SHG 14.5 14.5 13.2 10.8 17 17 16 12.7 19 19 18.3 14.1

CMP 2.27 2.27 2.3 2.34 2.3 2.3 2.32 2.35 2.32 2.32 2.33 2.36

581C036 (3 Tons)

Temp (F) Air Entering Evaporator -- CFM/BF

Air Ent 900/0.10 1200/0.13 1500/0.16

Condenser Air Entering Evaporator -- Ewb (F)

(Edb) 57 62 67 72 57 62 67 72 57 62 67 72

75

TCG 32 34.5 38.9 42.8 35.1 37.1 40.9 44.9 38.1 38.5 42.2 45.9

SHG 32 28.9 25 20.4 35.1 33.6 28.3 22.3 38.1 37.4 31.2 23.9

CMP 1.94 1.96 1.98 2 1.96 1.97 1.99 2.01 1.98 1.98 2 2.02

85

TCG 30.9 33.2 37.5 41.4 33.8 34.9 39.4 43.3 36.9 37 40.5 44.3

SHG 30.9 28.3 24.5 19.8 33.8 32.5 27.8 21.8 36.9 36.7 30.7 23.3

CMP 2.19 2.21 2.24 2.26 2.22 2.23 2.25 2.27 2.24 2.24 2.26 2.28

95

TCG 29.5 31.4 35.4 39.7 31.8 32.3 37.7 41.5 35.1 35.2 38.8 42.5

SHG 29.5 27.3 23.6 19.2 31.8 31.2 27.2 21.2 35 35.2 30 22.8

CMP 2.47 2.49 2.52 2.54 2.5 2.51 2.54 2.56 2.53 2.53 2.54 2.56

105

TCG 28 29.5 33 38 29.5 29.5 34.7 39.7 32.3 32.2 36.8 40.8

SHG 28 26.4 22.6 18.6 29.4 29.4 26 20.7 32.3 32.2 29.5 22.5

CMP 2.78 2.79 2.83 2.86 2.81 2.81 2.85 2.87 2.84 2.84 2.86 2.88

115

TCG 26.3 27.1 30.7 35.2 27.6 27.6 31.1 37.6 29.6 29.5 32.9 38.5

SHG 26.3 25.3 21.7 17.7 27.6 27.6 24.5 20 29.6 29.5 27.8 21.9

CMP 3.1 3.11 3.16 3.2 3.15 3.15 3.18 3.22 3.17 3.17 3.2 3.23

125

TCG 24.4 24.7 28.1 32.1 25.5 25.5 27.5 33.7 27 27 28.5 35.8

SHG 24.4 24.1 20.7 16.6 25.5 25.4 22.9 18.8 27 27 26 21.2

CMP 3.45 3.46 3.51 3.56 3.51 3.51 3.53 3.59 3.53 3.53 3.55 3.6

LEGEND NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

Where: h

ewb

= Enthalpy of air entering evaporator coil.

3. The SHC is based on 80 F edb temperature of air entering evapor

a

tor coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC.

Correction Factor = 1.10 x (1 – BF) x (edb – 80)

B

F—Bypass Factor

E

db — Entering Dry Bulb

E

wb — Entering Wet Bulb

C

OMP — Compressor Power kw

S

HG — Gross Sensible Capacity (1000 Btuh)

T

CG — Compressor Cooling Capicity (1000 Btuh)

t

ldb

=t

edb

–

sensible capacity (Btuh)

1.10 x cfm

t

lwb

= Wet-bulb temperature corresponding to enthalpy of air

leaving evaporator coil (h

lwb

)

h

lwb

=h

ewb

–

total capacity (Btuh)

4.5 x cfm