—15—

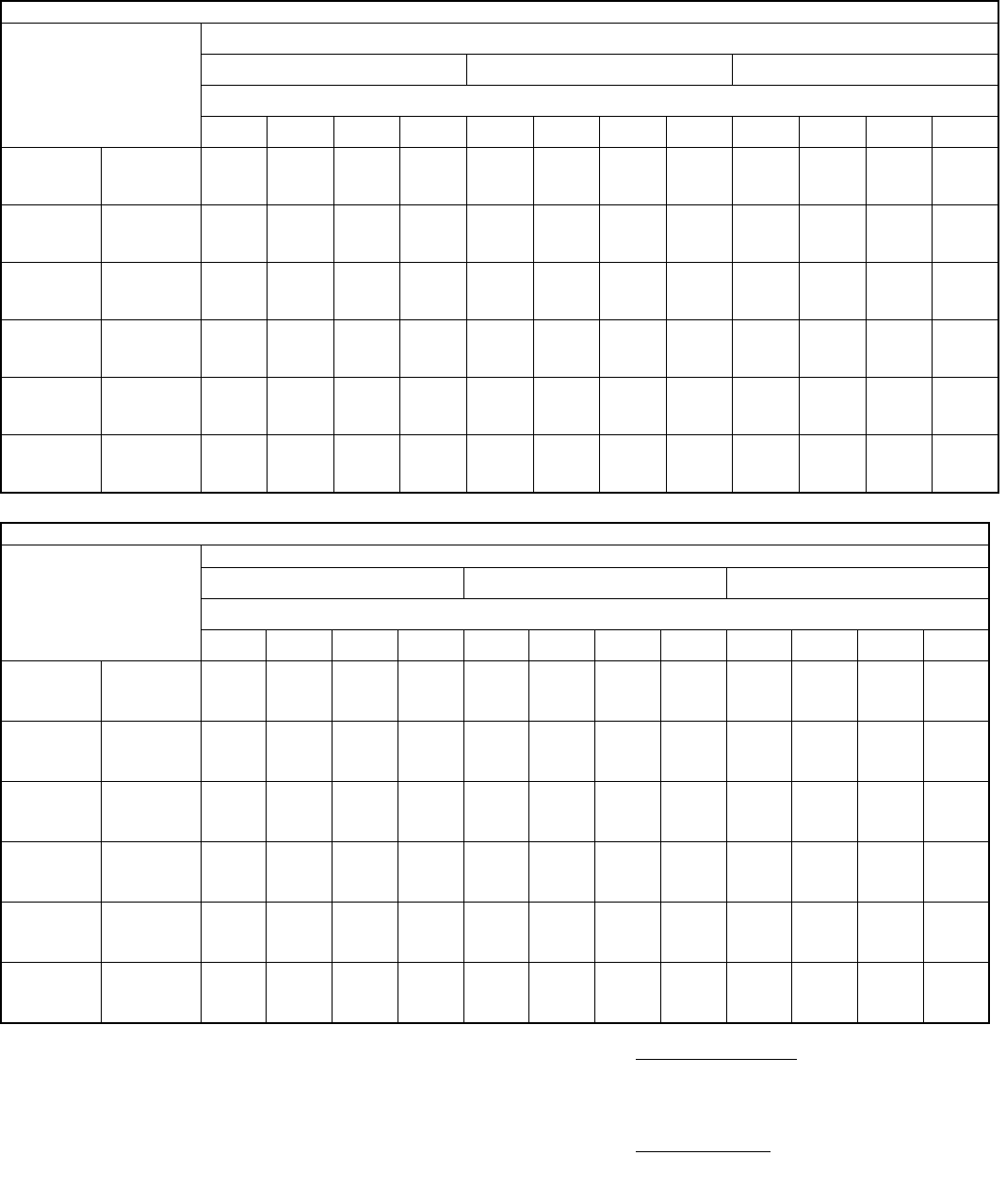

PERFORMANCE DATA (cont)

STANDARD INDOOR ECM MOTOR

COOLING CAPACITIES (cont)

574B048 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

Evaporator Air—CFM/BF

1260/0.06 1400/0.06 1600/0.08

Evaporator Air — Ewb (F)

62 63* 67 72 62 63* 67 72 62 63* 67 72

75

TC

SHC

kW

45.0 45.8 49.6 54.7 46.7 47.3 51.2 56.3 48.1 48.7 52.5 57.8

39.3 32.0 33.4 27.2 42.6 34.3 35.8 28.9 45.8 36.8 38.4 30.6

3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.5 3.4 3.4 3.4 3.5

85

TC

SHC

kW

42.8 43.6 47.2 52.1 44.3 44.9 48.6 53.5 45.6 46.1 49.9 54.8

38.2 30.9 32.3 26.2 41.3 33.2 34.7 27.7 44.3 35.5 37.3 29.4

3.7 3.7 3.8 3.8 3.7 3.7 3.8 3.8 3.8 3.8 3.8 3.8

95

TC

SHC

kW

40.6 41.3 44.7 49.4 41.8 42.4 46.0 50.7 44.2 43.7 47.0 51.8

36.9 29.8 31.2 25.2 39.9 32.0 33.6 26.7 43.0 34.6 36.1 28.3

4.1 4.1 4.2 4.2 4.1 4.1 4.2 4.2 4.2 4.1 4.2 4.2

105

TC

SHC

kW

38.2 38.9 42.1 46.4 39.6 39.8 43.1 47.6 41.5 40.8 44.0 48.5

35.7 28.7 30.1 24.0 38.3 30.7 32.3 25.5 40.0 33.2 34.8 27.0

4.6 4.6 4.6 4.6 4.6 4.6 4.6 4.7 4.6 4.6 4.6 4.7

115

TC

SHC

kW

35.7 36.3 39.3 43.3 38.2 37.1 40.1 44.2 38.7 37.9 40.8 45.0

34.4 27.5 28.9 22.9 35.7 29.5 31.0 24.3 38.2 31.8 33.5 25.8

5.0 5.0 5.1 5.1 5.1 5.0 5.1 5.1 5.1 5.1 5.1 5.1

125

TC

SHC

kW

33.4 33.4 36.2 39.4 34.6 34.1 36.9 40.5 36.1 34.8 37.5 41.2

32.1 26.2 27.6 21.5 33.8 28.2 29.7 22.9 35.6 30.2 31.9 24.4

5.6 5.6 5.6 5.7 5.6 5.6 5.6 5.6 5.6 5.6 5.6 5.6

574B060 COOLING PERFORMANCE TABLE

Temp (F)

Outdoor Air

Entering

Condenser

Evaporator Air — CFM/BF

1500/0.004 1750/0.007 2000/0.01

Evaporator Air — Ewb (F)

62 63* 67 72 62 63* 67 72 62 63* 67 72

75

TC

SHC

kW

57.2 58.2 62.4 68.1 58.8 59.7 64.0 69.8 60.0 60.8 64.9 70.8

49.4 47.9 41.6 33.8 53.6 51.8 44.5 35.4 57.6 55.4 47.1 36.8

4.1 4.1 4.2 4.2 4.2 4.3 4.3 4.4 4.4 4.4 4.5 4.6

85

TC

SHC

kW

54.7 55.6 59.7 65.2 56.2 57.0 61.1 66.6 57.4 58.1 61.9 67.4

48.2 46.7 40.4 32.6 52.4 50.5 43.2 34.2 56.3 54.2 45.8 35.6

4.5 4.5 4.6 4.7 4.7 4.7 4.8 4.9 4.8 4.9 5.0 5.0

95

TC

SHC

kW

52.2 53.0 56.9 62.0 53.5 54.3 58.0 63.2 55.0 55.3 58.7 64.1

47.0 45.4 39.2 31.4 51.1 49.2 41.9 32.9 55.0 52.9 44.5 34.4

5.0 5.0 5.1 5.2 5.1 5.2 5.3 5.3 5.2 5.3 5.5 5.5

105

TC

SHC

kW

49.4 50.2 53.8 58.7 50.7 51.4 54.8 59.6 52.5 52.4 55.4 60.2

45.7 44.1 37.9 30.1 49.8 47.9 40.6 31.6 52.5 51.6 43.2 33.0

5.5 5.6 5.6 5.7 5.7 5.7 5.8 5.9 5.8 5.8 6.0 6.1

115

TC

SHC

kW

46.5 47.2 50.5 55.0 48.1 48.3 51.3 56.8 49.7 49.7 51.8 57.0

44.3 42.7 36.4 28.7 48.1 46.6 39.2 30.6 49.7 49.7 41.8 31.7

6.1 6.2 6.2 6.3 6.2 6.3 6.4 6.4 6.4 6.4 6.6 6.6

125

TC

SHC

kW

43.3 43.9 46.7 52.2 45.2 45.1 47.4 52.5 46.4 46.4 47.9 52.2

42.8 41.2 34.9 27.8 45.2 45.1 37.6 28.9 46.4 46.4 40.2 29.7

6.7 6.8 6.8 6.8 6.8 6.9 7.0 7.0 7.0 7.0 7.2 7.2

LEGEND

BF — Bypass Factor

Ewb — Entering Wet-Bulb

kW — Total Unit Power Input

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Cooling Capacity (1000 Btuh)

ECM — Electronic Computated Motor

* — TVA Conditions (75°F entering dry bulb)

NOTES:

1. Ratings are net; they account for the effects

of the evaporator-fan motor power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

3. The following formulas may be used:

sensible capacity (Btuh)

t=t؊

ldb edb

1.10 x cfm

t = Wet-bulb temperature corresponding to enthalpy of air leaving

lwb

evaporator coil (h )

lwb

total capacity (Btuh)

h=h؊

lwb ewb

4.5 x cfm

Where: h = Enthalpy of air entering evaporator coil

ewb

4. The SHC is based on 80°F edb temperature of air entering evaporator

coil. Below 80°F edb, subtract (Corr Factor x CFM) from SHC above

80°F edb, add (Corr Factor x CFM) to SHC Correction Factor = 1.10 x

(1 – BF) x (edb – 80)