12. Reconnect wires to the following components:

a. Draft safeguard switch

b. Inducer motor

c. Pressure switch

d. Limit overtemperature switch

e. Gas valve

f. Edge connector leading to control box

13. Reconnect vent pipe to relief box. Replace vent pipe

enclosure (downflow furnace only).

14. Replace blower access door only and secure with 2 screws

(downflow furnace only).

15. Turn on electrical power and gas.

16. Set thermostat and check furnace for proper operation.

WARNING: Never use a match or other open flame to

check for gas leaks. Use a soap-and-water solution. A

failure to follow this warning could result in fire, personal

injury, or death.

17. Check for gas leaks.

18. Replace control access door.

D. Electrical Controls and Wiring

NOTE: There may be more than 1 electrical supply to unit.

The electrical ground for 115-v wiring must be maintained

properly. Refer to Fig. 8 for field wiring information and to Fig. 9

for unit wiring information.

With power disconnected to unit, check all electrical connections

for tightness. Tighten all screws on electrical connections. If any

smoky or burned connections are noticed, disassemble the connec-

tion, clean all parts and stripped wire, and reassemble properly and

securely. Electrical controls are difficult to check without proper

instrumentation; therefore, reconnect electrical power to unit and

observe unit through 1 complete operating cycle.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on the main control board. Any direct shorts during installation,

service, or maintenance could cause this fuse to blow. If fuse

replacement is required, use ONLY a 3-amp fuse of identical size.

E. Pilot

Check the pilot and clean if necessary at the beginning of each

heating season. The pilot flame should be high enough for proper

impingement of the flame sensing element (or thermocouple) and

to light the burners. Remove the accumulation of soot and carbon

from the flame sensing element (or thermocouple). Refer to Fig. 7

for proper location of pilot on burner assembly.

F. Troubleshooting

Page 8 contains a troubleshooting chart. This chart can be a useful

tool in isolating furnace operation problems. Beginning with the

word "Start," answer each question and follow the appropriate

arrow to the next item.

The chart will help identify the problem or failed component. After

replacing any component, verify correct operating sequence as

indicated by bold arrows.

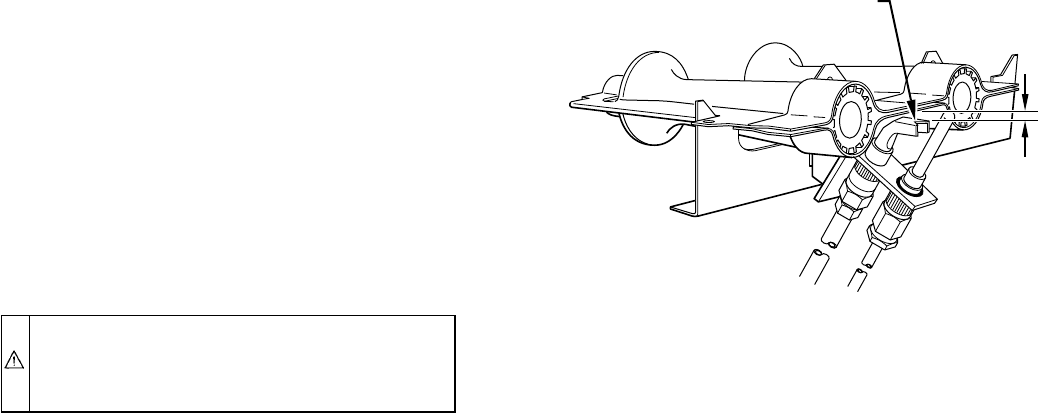

Fig. 7—Position of Pilot to Burner

A91249

1

/

8

″

PILOT HEAD V–NOTCH FALLS

DIRECTLY BELOW FRONT EDGE

OF BURNER CARRYOVER.

—5—