b. Remove blower and control access doors.

c. Release filter retainer from clip at front of furnace

casing. (See Fig. 4.) For side return, clips may be used on

either or both sides of the furnace.

d. Slide filter out.

e. Furnaces are equipped with permanent, washable filters.

Clean filters with tap water. Spray water through filter in

opposite direction of airflow.

f. Rinse and let dry. Oiling or coating of filter is not

recommended or required.

g. Reinstall filter.

h. Replace access doors.

i. Restore electrical power to furnace.

B. Blower Motor and Wheel

For long life, economy, and high efficiency, clean accumulated dirt

and grease from the blower wheel and motor annually.

The following steps should be performed by a qualified service

technician:

Some motors have prelubricated sealed bearings and require no

lubrication. These motors can be identified by the absence of oil

ports on each end of the motor. For those motors with oil ports,

lubricate motor every 5 years if motor is used on intermittent

operation (thermostat FAN switch in AUTO position), or every 2

years if motor is in continuous operation (thermostat FAN switch

in ON position).

Remember to disconnect the electrical supply before removing

access doors.

Clean and lubricate as follows:

1. Remove 2 screws from blower access door (downflow

furnace only). Remove blower access door.

2. Remove vent pipe enclosure (downflow furnace only) and

disconnect short piece of vent pipe from relief box.

3. Disconnect wires from auxiliary limit on blower housing

(downflow furnace only).

4. Remove control box.

5. Remove electrical leads from numbered side of blower

speed selector. (See Fig. 4 and 5.) Note location of wires for

reassembly.

6. Remove screws holding blower assembly to blower deck

and slide blower assembly out of furnace.

7. Squeeze side tabs of blower speed selector and pull it out of

blower housing.

8. Loosen screw in strap holding motor capacitor to blower

housing and slide capacitor out from under strap.

9. Mark blower wheel, motor, and motor support in relation to

blower housing before disassembly to ensure proper reas-

sembly.

10. Loosen setscrew holding blower wheel on motor shaft.

11. Remove bolts holding motor mount to blower housing and

slide motor and mount out of housing. Disconnect ground

wire attached to blower housing before removing motor.

12. Lubricate motor (when oil ports are provided).

a. Remove dust caps or plugs from oil ports located at each

end of motor.

b. Use a good grade of SAE 20 nondetergent motor oil and

put 1 teaspoon, 5 cc, 3/16 oz, or 16 to 25 drops in each

oil port. Do not over-oil.

c. Allow time for total quantity of oil to be absorbed by

each bearing.

d. Wipe excess oil from motor housing.

e. Replace dust caps or plugs on oil ports.

13. Remove blower wheel from housing.

a. Mark cutoff location to ensure proper reassembly.

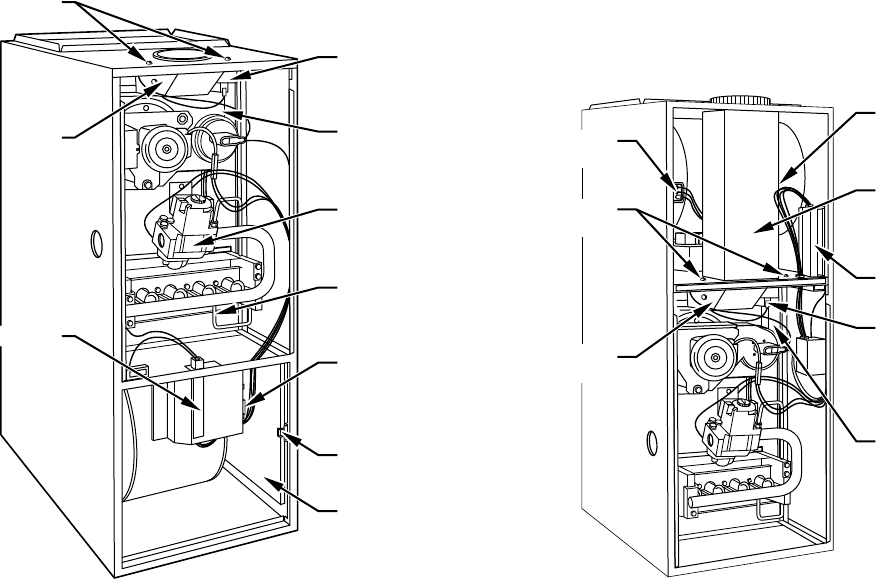

Fig. 4—Model 394HAD Upflow

A92178

DRAFT

SAFEGUARD

SWITCH

RELIEF

BOX

MOUNTING

SCREWS

FLUE

COLLECTOR

BOX

GAS

VALVE

PILOT

SPEED

SELECTOR

FILTER

RETAINER

WASHABLE

FILTER

CONTROL

BOX

Fig. 5—Model 396HAD Downflow

A92179

VENT PIPE

ENCLOSURE

CONTROL

BOX

DRAFT

SAFEGUARD

SWITCH

FLUE

COLLECTOR

BOX

AUXILIARY

LIMIT SWITCH

(NOT VISIBLE)

SPEED

SELECTOR

MOUNTING

SCREWS

RELIEF

BOX

—3—