—2—

A99109

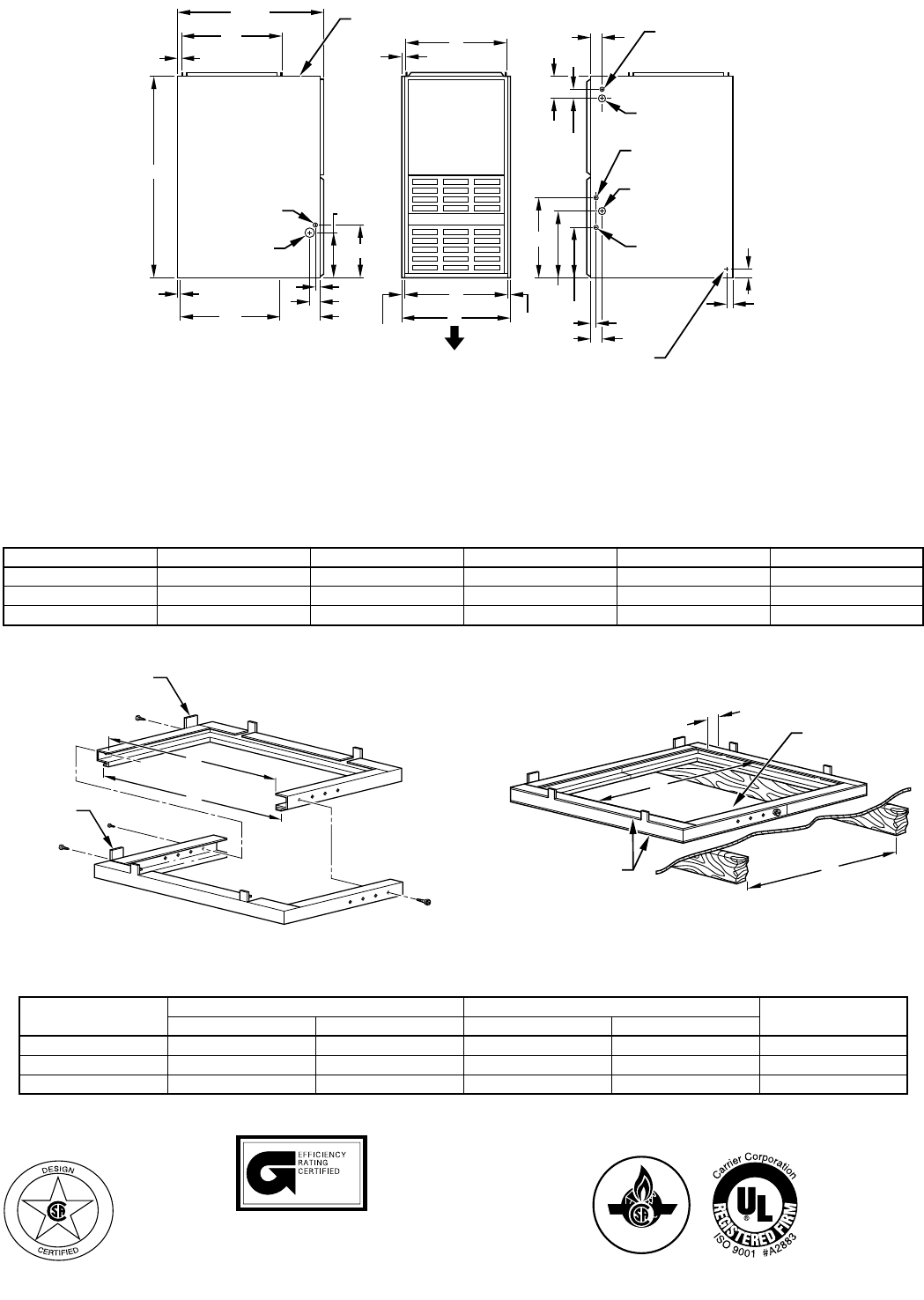

DIMENSIONS (In.)

UNIT SIZE A D E VENT CONN (Dia) SHIPPING WEIGHT (Lb)

036060 14-3/16 12-9/16 12-11/16 4 145

048080 17-1/2 15-7/8 16 4 154

060100 21 19-3/8 19-1/2 4 181

4

3

⁄

16

″

2″

2

15

⁄

16

″

13

⁄

16

″

11

⁄

16

″

9

1

⁄

8

″

10

1

⁄

4

″

1

1

⁄

16

″

2

1

⁄

8

″

8

1

⁄

4

″

10

1

⁄

4

″

1

1

⁄

16

″

2

1

⁄

8

″

16

1

⁄

16

″

13

5

⁄

16

″

19″

11

⁄

16

″

13

⁄

16

″

11

⁄

16

″

20″

28

1

⁄

2

″

39

7

⁄

8

″

D

5

⁄

8

″ TYP

1

″ TYP

E

A

AIRFLOW

OUTLET

INLET

1

⁄

2

″ DIA

THERMOSTAT

WIRE ENTRY

7

⁄

8

″ DIA

ACCESSORY

7

⁄

8

″ DIA

ACCESSORY

DIMPLES TO DRILL HOLES

FOR HANGER BOLTS (4 PLACES)

IN HORIZONTAL POSITION

ADDITIONAL

7

⁄

8

″ DIA K.O. ARE

LOCATED IN THE TOP PLATE

AND BOTTOM PLATE

NOTE:

7

⁄

8

″ DIA HOLE

POWER ENTRY

1

1

⁄

2

″ DIA

R.H. GAS ENTRY

7

⁄

8

″ DIA

ACCESSORY

1

3

⁄

4

″ DIA HOLE

GAS ENTRY

VENT CONNECTION

1. Two additional

7

⁄8

-

in. dia holes are located in the top plate.

2. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufacturer's recommendations for equivalent diameters.

a. For 800 CFM–16-in. round or 14

1

⁄2 x 12-in. rectangle.

b. For 1200 CFM–20-in. round or 14

1

⁄2 x 19

1

⁄2-in. rectangle.

c. For 1600 CFM–22-in. round or 14

1

⁄2 x 23

1

⁄4-in. rectangle.

d. For airflow requirements above 1800 CFM, must use entire return air opening.

NOTES:

ACCESSORY DOWNFLOW SUBBASE

A88207

Disassembled

A88206

Assembled

LOCATING

TAB

LOCATING

TAB

1

2

3

4

4

3

2

1

B

D

C

A

1

1

⁄

4

″ TYP

PLENUM

OPENING

FACTORY-SUPPLIED

FIELD-INSTALLED

INSULATION

MEETS DOE RESIDENTIAL CONSERVATION

SERVICES PROGRAM STANDARDS.

Before purchasing this appliance, read important

energy cost and efficiency information available

from your retailer.

CERTIFIED

DIMENSIONAL DATA (In.)

*

The plenum should be constructed 1/4 in. smaller in width and depth than the plenum dimensions shown above.

FURNACE WIDTH

PLENUM OPENING

*

FRAMED FLOOR HOLE

HOLE NO. FOR

WIDTH ADJUSTMENTABCD

14-3/16 11-13/16 19 13-7/16 20-3/8 4

17-1/2 15-1/8 19 16-3/4 20-3/8 3

21 18-5/8 19 20-1/4 20-3/8 2

ama