3

On rooftop applications, locate unit at least 6 in. (152.4 mm) above

roof surface.

Operating Ambient

The minimum outdoor operating ambient in cooling mode is

55_F/12.78_C without low ambient cooling enabled, and the

maximum outdoor operating ambient in cooling mode is

125_F/51.67_C. On Evolution communicating systems only, for

both 180A and 187A models, low ambient cooling is available to

0_F/-- 17.78_C.

Make Piping Connections

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal

injury or death.

Relieve pressure and recover all refrigerant before system

repair or final unit disposal Use all service ports and open

all flow--control devices, including solenoid valves.

!

WARNING

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not leave system open to atmosphere any longer than

minimum r equired for installation. POE oil in compressor is

extremely susceptible to moisture absorption. Always keep

ends of tubing sealed during installation.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

If ANY refrigerant tubing is buried, provide a 6 in. (152.4

mm) vertical rise at service valve. Refrigerant tubing lengths

up to 36 in. (914.4 mm) may be buried without further

special consideration. Do not bury lines longer than 36 in.

(914.4 mm).

Outdoor units may be connected to indoor section using

field--supplied refrigerant grade tubing of correct size and

condition. For tubing requirements beyond 80 ft (24.38 m),

substantial capacity and performance losses can occur . Following

the recommendations in the Residential Piping and Longline

Guideline will reduce these losses. Refer to Table 1 for field tubing

diameters. Refer to Table 2 for accessory requirements.

There are no buried-- line applications greater than 36 in. (914.4

mm).

If refrigerant tubes or indoor coil are exposed to atmosphere, they

must be evacuated to 500 microns to eliminate contamination and

moisture in the system.

Outdoor Unit Connected to Factory Approved Indoor

Unit:

Outdoor unit contains correct system refrigerant charge for

operation with factory approved ARI rated indoor unit with highest

sales volume when connected by 15 ft (4.57 m) of field--supplied

or factory--accessory tubing, and factory supplied filter drier.

Check refrigerant charge for maximum efficiency.

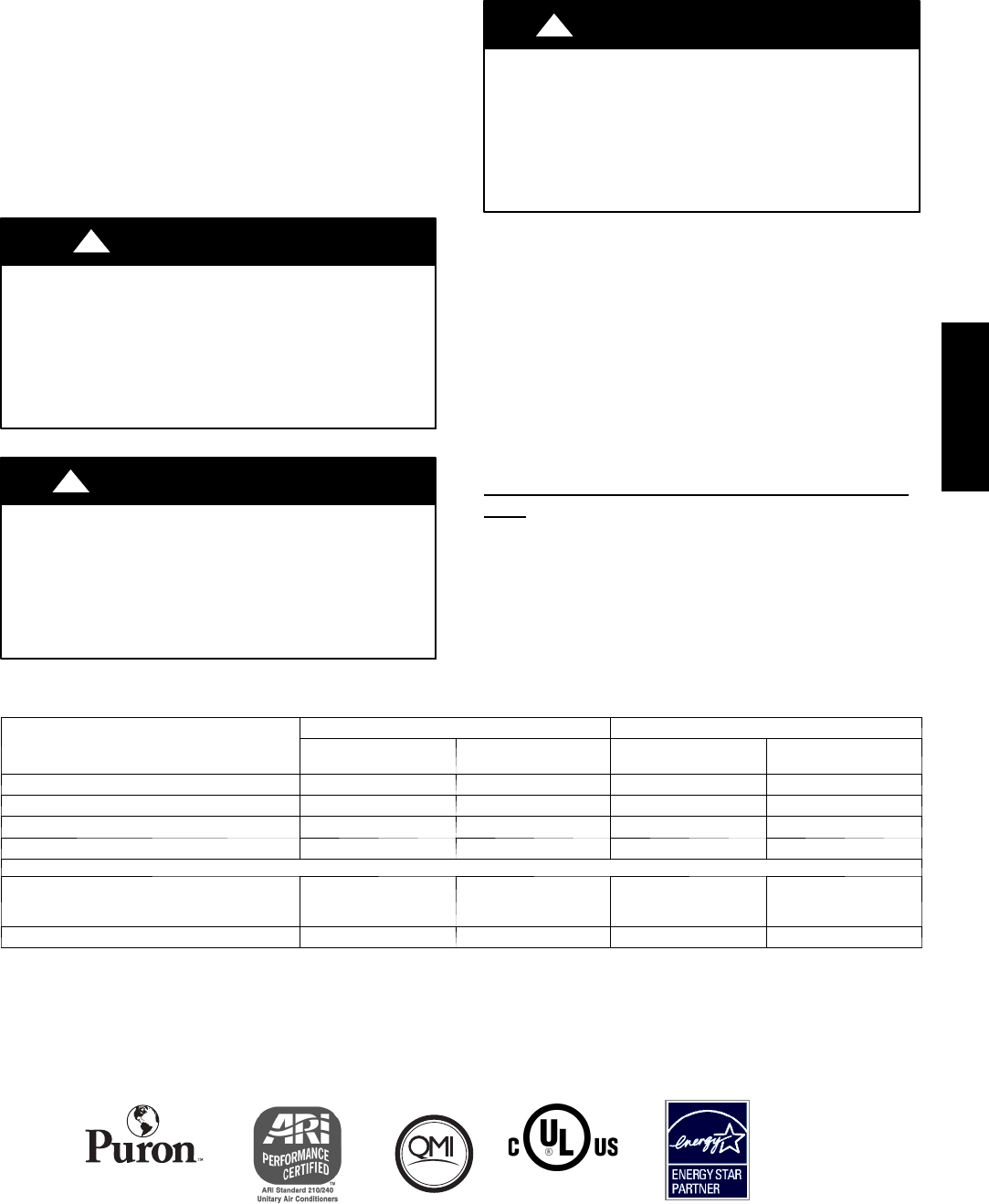

Table 1 – Refrigerant Connections and Recommended Liquid and Vapor Tube Diameters (in.)

UNIT SIZE

LIQUID RATED VAPOR*

Connection

Diameter

Tube

Diameter

Connection

Diameter

Tube

Diameter

187A024 3/8 3/8 5/8 5/8

187A036 3/8 3/8 3/4 3/4

187A048 3/8 3/8 7/8 7/8

187A060 3/8 3/8 7/8 1 --- 1/ 8

180A024

180A036

180A048

3/8 3/8 7/8 7/8

180A060 3/8 3/8 7/8 1 --- 1/ 8

* Units are rated with 25 ft. (7.6 m) of lineset. See Product D ata sheet for performance data when using different size and length linesets.

Notes:

1. Do not apply capillary tube or fixed orifice indoor coils to these units.

2. For Tubing Set lengths between 80 and 200 ft. (24.38 and 60.96 m) horizontal or 20 ft. (6.10 m) vertical differential (250 ft./76.2 m Total Equivalent Length),

refer to the Residential Piping and Longline Guideline.

the environmentally sound refrigerant

REGISTERED

ISO 9001:2000

This product has been designed and manufactured to

meet Energy Star® criteria for energy effici ency when

matched with ap p rop riate coil components. However,

proper refrigerant charge and proper air flow are critical

to achieve rated capacity and efficiency. Installation of

this product should follow all manufacturing refrigerant

chargingand airflow instructions. Failure to confirm

proper charge and airflowmay reduce energy

efficiency and shorten equi pment life.

180A / 187A