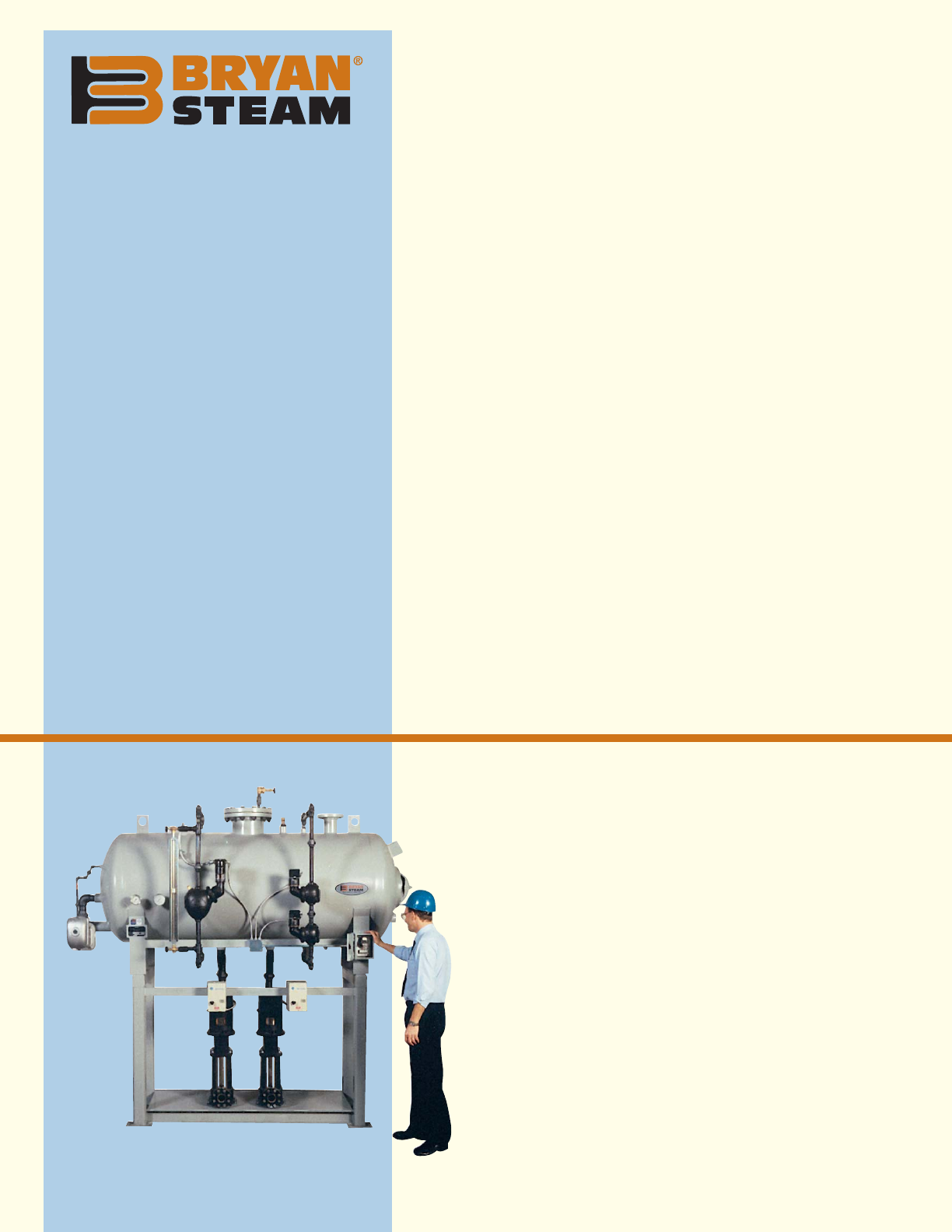

Spray Type and Tray

Type Deaerator Features

• Constructed and Stamped to ASME

Section VIII, Division 1 for 50 psig

• 1/16" corrosion allowance

• Easily accessible manway

• 10 minutes of deaerated water

storage to overflow

• All internal surfaces that contact

undeaerated water are constructed

of stainless steel

• 2-stage deaeration

• Structural steel stand/pump platform

• Available as completely packaged

unit including pumps and control

panel

Why deaerate

boiler feedwater?

There are many advantages to deaerating water prior

to boiler input, but they all boil down to reduced cost

operations.

• Water is heated during deaeration to near the

temperature of the boiler water, thus minimizing the

risk of thermal shock damage to a high value

boiler system.

• The deaerating process removes noncondensible

gases (oxygen and carbon-dioxide) which tend

to act as insulators inhibiting the transfer of heat

within the boiler.

• Removal of corrosive oxygen and carbon-dioxide

controls corrosion within the boiler and piping,

extending the life expectancy of the system and

reducing maintenance cost.

• Higher temperature feedwater reduces the drop in

boiler operating pressure which can occur when

cold water is added.

• Recycling of steam from vents and flash steam from

traps that would otherwise be vented to the atmos-

phere can result in appreciable energy savings.

• Mechanical deaeration by a feedwater deaerator can

cut the amount of chemical consumables used for

water conditioning for a continuing operating

cost saving.

Reduce costs/improve efficie

Bryan spray-scrubber type deaerators offer a competi-

tive alternative for feedwater deaeration. The initial

investment is lower, yet they offer comparable results,

particularly where wide or rapid fluctuations in load are

not anticipated. The spray type deaerator may also be

advantageous in situations where headroom in the

boiler room is restricted.

The Bryan spray type deaerator is rated for oxygen

removal to .005cc/l (7 PPB) and CO

2

to zero measurable

across its entire operating range. With its all stainless

steel spring loaded spray valve and second stage steam

scrubber, the spray type deaerator is a good choice for

most deaerator applications.

Units are available with a complete range of boiler feed-

pumps and control options making them a total deaera-

tor package with minimal amount of field assembly.

4

Pressurized

Spray Type Deaerator

Capacities from 5,000 pph - 60,000 pph

Model DSH-150-5-2-2