Date: 8-4-2010

Revision: 0

Form: 2396

2.3 BOILER COMMISSIONING

NOTE:

All of the installation instructions found in section

1 must be completed before commissioning the

boiler.

WARNING:

The following procedures must be

followed carefully before putting the

boiler in operation. Failure to do so

will present severe hazards to

equipment, operating personnel and

building occupants.

2.3.1 MODULATION

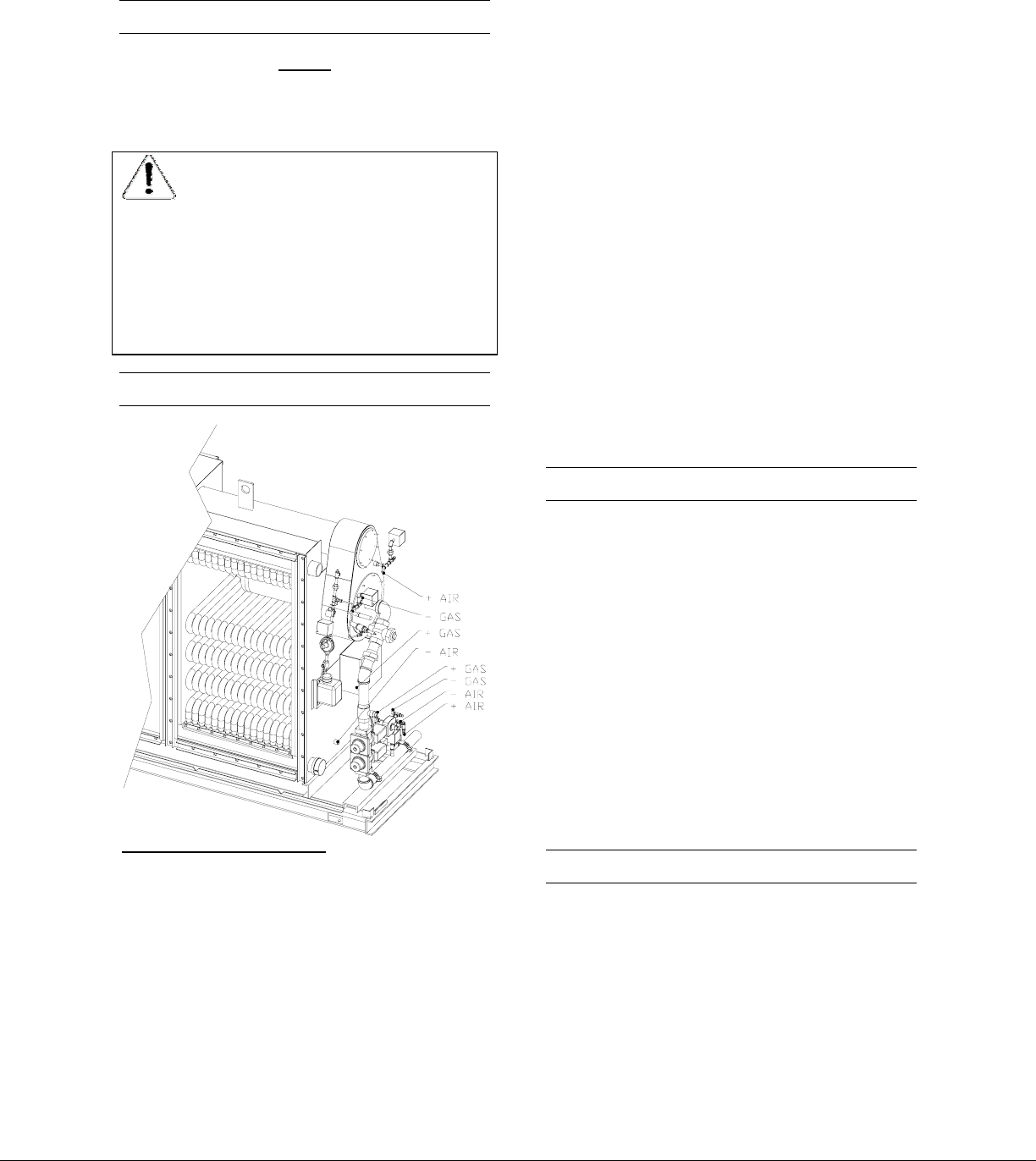

Figure 39 Air / Gas Ratio Tappings

Modulation on the Triple-flex boiler is

accomplished with air / gas ratio control. The

system consists of two major components, a

blower (Figure 10 item 6) and a regulating gas

valve (Figure 7 item 3). The blower is variable

speed and provides combustion air to the

burner. The blower rpm is controlled by a PWM

(pulse width modulation) signal. The PWM

signal increases or decreases as the load

increases or decreases in the hydronic system.

The regulating gas valve is a 1:1 differential

pressure air / gas ratio controller. This means

that the control adjusts the same pressure

difference on the gas side as it senses on the

airside. The airside pressure is the difference

between the pressure in the burner housing and

the pressure downstream of the furnace section.

The gas side pressure is the difference between

the pressure upstream and downstream of the

gas limiting orifice valve. For the locations of the

+/- gas and air connections see (Figure 39). Air

to gas ratios are adjusted with the gas limiting

orifice valve (Figure 7 item 26).

During the burner pre-purge period, when the

gas valve is closed, only the air pressure

difference acts on the regulator causing the air

diaphragm to move to the left and closes the

regulating hydraulic bypass valve. When the

actuator is powered, the gas valve begins to

open. The downstream gas pressure difference

immediately begins to increase until the gas

pressure difference is in balance with the air

pressure difference.

2.3.2 TEST SETUP

Connect a u-tube manometer to the gas

manifold pressure tapping (Figure 7 item 12).

Connect a 0 – 5 psi gauge in the port provided in

the low gas pressure switch connection (Figure

7 item 28).

Connect a u-tube manometer to the pilot gas

pressure port provided (Figure 7 item 14).

A suitable combustion analyzer shall be used for

measuring O2, CO, and Nox levels. The

analyzer probe should be inserted in the stack

above the boiler outlet and before any draft

controls. Calibration is required for the Nox and

CO cells at the time of commissioning.

2.3.3 PRE CHECKS AND SETUP

Close the manual gas cock (Figure 7 item 4).

35