IF STOVE RUNS OUT OF PELLETS

The fire goes out and the auger motor and blowers will run until the stove cools. This will take 30 to 45 minutes.

After the stove components stop running the “On/Off” and the BAR GRAPH lights stay on for 10 minutes.

After the 10 minutes the “3” light on the bar graph will flash and the “On/Off” light will go off.

To restart, refill hopper and press “Fuel Feed” button until pellets begin to fall into burnpot. Press “On/Off” button.

DAMPER CONTROL

The damper control rod on the stove’s lower left side adjusts the combustion air. This control is necessary due to the varied burn

characteristics of individual installations, different pellet brands and pellet feed rates. It allows you to improve the efficiency of your stove.

Providing correct combustion air will reduce the frequency of cleaning your glass door and prevent the rapid buildup of creosote inside your

stove and chimney.

You should adjust the damper based on the fire’s appearance. A low, reddish, dirty fire can be improved by pulling the damper out slightly. A

“blow torch” fire can be improved by pushing the damper in a bit.

As a general rule, on lower feed rate settings, the damper should be in farther. On higher feed rates, the damper should be more open.

Through trial and error, you will find the best setting. Consult your dealer if you need help.

NOTE: On “1”, damper should be out approximately ¼” to ½”. If damper is out too far, it can cause the fire to go out.

REFUELING

We recommend that you not let the hopper drop below ¼ full.

KEEP HOPPER LID CLOSED AT ALL TIMES EXCEPT WHEN REFILLING. DO NOT OVERFILL HOPPER.

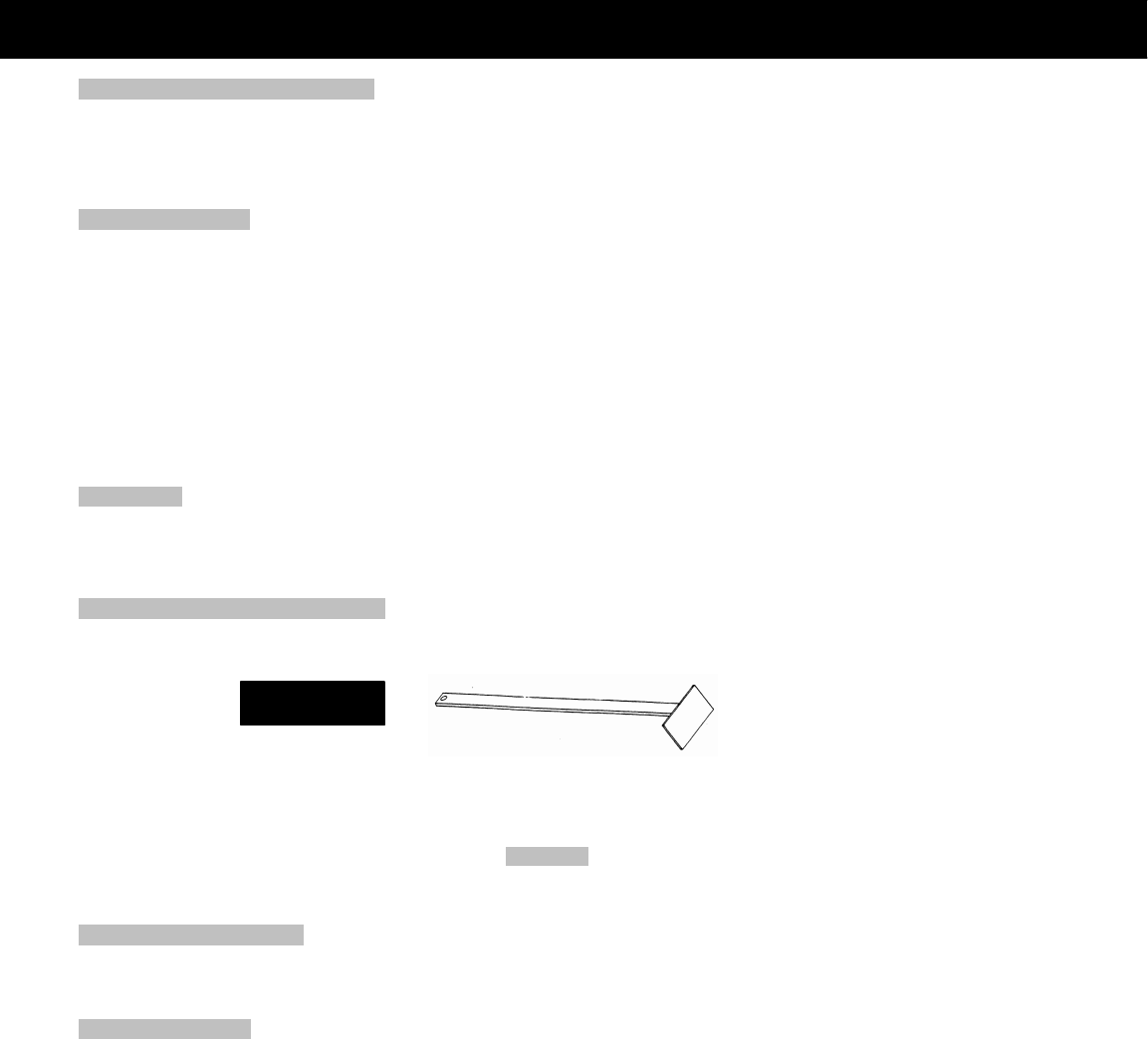

BRECKWELL MAINTENANCE TOOL

A tool has been provided to help with the following functions:

a. Stirring pellets in hopper – unlike liquids in a tank, pellets do not drain evenly into the auger. Bridging across the opening can occur.

Pellets can hang up on the sides of the hopper. Occasionally “stirring” the hopper can help.

NOTE: To help prevent bridging of pellets, common wax paper can be rubbed on the sidewalls and bottom of the hopper.

b. Cleaning heat exchanger tubes – see instructions in “CLEANING”.

c. Scrape ashes from burnpot.

SHUTDOWN PROCEDURE

Turning your Breckwell stove off is a matter of pressing the “On/Off” control panel switch. The green light will go out. The blowers will

continue to operate until internal firebox temperatures have fallen to a preset level.

SAFETY FEATURES

a. Your stove is equipped with a resettable high temperature thermodisk. This disc has a reset button on its backside. This safety switch

has two functions.

1. To recognize an overheat situation in the stove and shut down the fuel feed or auger system.

2. To recognize an internal control board failure and shut down the fuel feed or auger system.

NOTE: Like a circuit breaker, once tripped, the reset button will have to be pushed before restarting your stove. The manufacturer

recommends that you call your dealer if this occurs as this may indicate a more serious problem. A service call may be required.

b. In case of a malfunctioning convection blower, a high-temperature thermodisk will automatically shut down the auger, preventing the

stove from overheating.

NOTE: Thermodisk must be reset after this occurs.

c. If the combustion blower fails, an air pressure switch will automatically shut down the auger.

NOTE: Opening the stove door for more than 30 seconds during operation will cause enough pressure change to activate the air switch,

shutting the fuel feed off. Close the door and press “On/Off” button to continue operation of your stove.

OPERATION

17

FIGURE 22