8 6 720 607 026

To check the draft:

Close all doors and windows to the outside.

Turn on all appliances that force air out of the building.

These include all exhaust/ventilation fans, furnaces, clothes

dryers, wood burning stoves, etc.

Open all doors between the 425 HN and these other

appliances.

With the control knob set fully clockwise and strong hot

water flow rate, run the unit for at least 10 minutes. The

425 HN is equipped with a Flue Gas Sensor; it’s mounted

on the right side of the draft diverter (Flue Gas Sensor #34

on page 17). If the main burners shut off during this test it

is because the Flue Gas Sensor has detected inadequate

venting. This is a serious health hazard and must be corrected.

Poor venting can result in soot building up inside the heater,

overheating of the heater and freezing of the heat exchanger

in a freezing environment, which is all a result of negative

air flow. Additional combustion air and/or improved venting

will be necessary to correct this.

WARNING

Note: The burners of an instantaneous “on demand” water

heater such as the 425 HN are only on at the time that hot

water is actually being used, the vent pipe is therefore cold

except for the short durations when hot water is being used,

it is therefore very important that the venting and air supply

be adequate to provide a good positive draft as soon as the

burners turn on.

The 425 HN instantaneous water heaters have built-in draft

diverters and are designed for indoor installation only. The

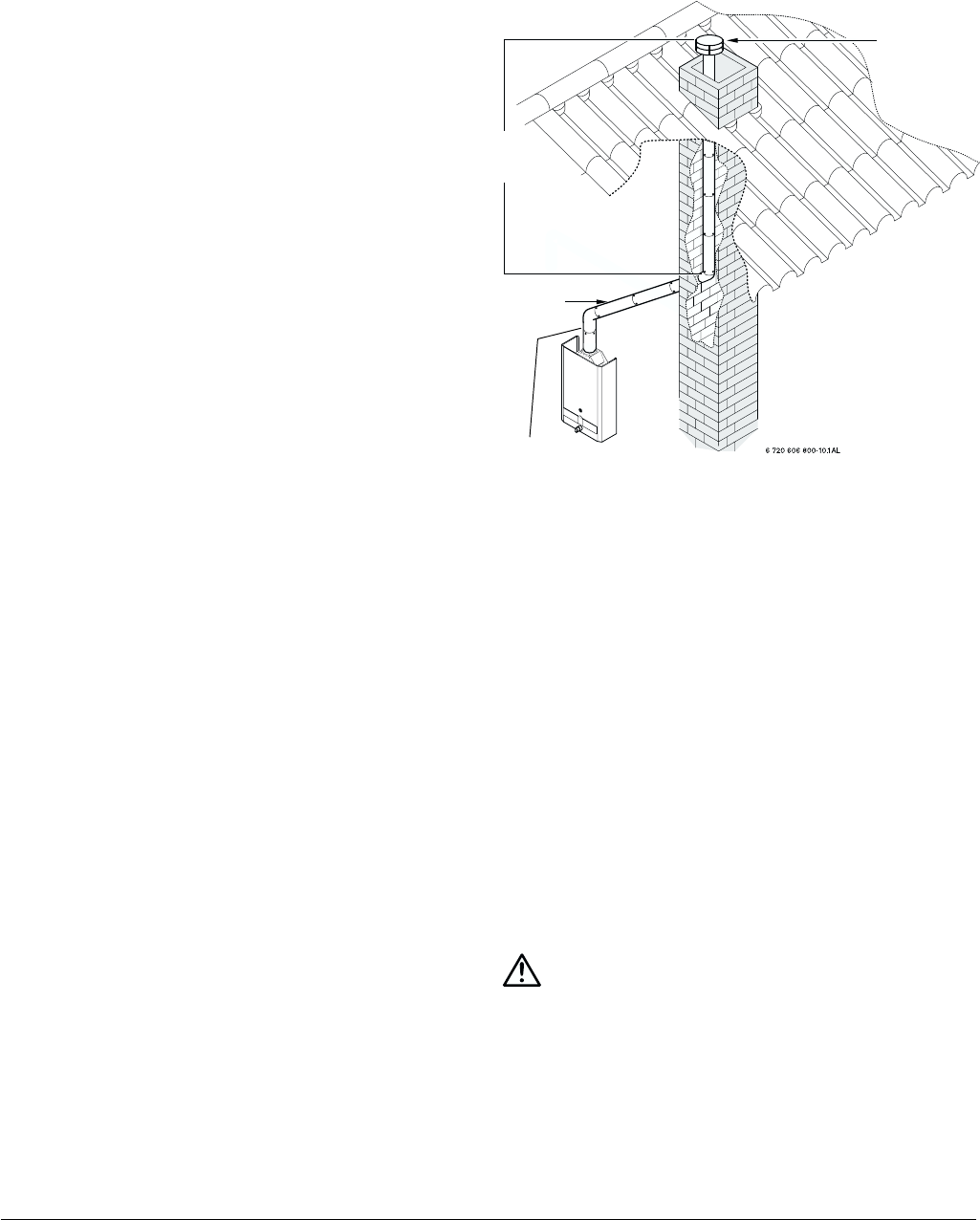

MASONRY CHIMNEYS

Gas vent

Vent

connector

Establish a one foot

rise before any elbows

Listed vent cap

Figure C

MASONRY CHIMNEY: Masonry chimneys shall be built and

installed in accordance with NFPS 211 or local codes. A

minimum 5” diameter gas vent pipe (metal double wall Type

B), or an approved clay flue liner or a listed chimney lining

system must be used when venting into a naturally drafting,

internal masonry chimney. 6 inch is required in elevations

greater than 2000 feet, see Fig. 4. Local codes may require

the use of both gas vent and an approved lining system

when venting into a masonry chimney. The Commonwealth

of Massachusetts requires the use of a listed liner. Lining

systems include approved clay flue lining, a listed chimney

lining system or other approved material that will resist

corrosion, erosion, softening, or cracking from exhaust flue

gases at temperatures up to 1800 degrees F. The lining

system must be listed for use with naturally drafting, draft

hood equipped gas appliances. Follow local codes and refer

to NFGC 54 and NFPA 58.

When connecting the water heater to a masonry chimney

the following connector guidelines must be followed for

safe and proper operation: An approved gas vent connector

must be attached to the top of the water heater and rise

vertically at least 12” before entering into an approved gas

vent connector elbow. Any gas vent section that is greater

than 45 degrees from the vertical is considered horizontal.

If a horizontal vent connector is to be used to connect the

vertical gas vent connector on the top of the water heater

to the masonry chimney, that approved horizontal gas vent

connector must be kept as short as possible and must be

sloped upwards at least ¼” per foot of its length. This

connector must be supported throughout its horizontal length.

This horizontal gas vent connection may be no greater than

75% of the total vertical gas flue vent within the chimney.

Also, an approved thimble or collar must be used when

penetrating a masonry chimney.

A) Existing INTERIOR Masonry Chimney

The metal gas vent pipe should be permanently mounted

inside the masonry chimney. Double wall Type B gas vent is

recommended. The masonry chimney may have to be tile

or metal lined before the insertion of the gas vent pipe;

check local codes for clarification. The lining material must

be listed for use only with naturally drafting, draft hood

equipped gas appliances. Follow manufactures instructions

for installation of listed lining material. You may not vent any

other fuel burning appliances into any free space remaining

in the chimney. The minimum vertical gas vent length within

the masonry chimney should be no less than 5 ft (1.5 m);

the vent terminator should extend at least 3 feet (0.9 m)

above where the chimney meets the roofline and at least 2

feet (0.6 m) higher than any vertical wall or similar obstruction

within 10 feet (3.1 m). The top of the gas vent should have

an approved vent terminator. See Figure C.

B) Tile Lined INTERIOR Masonry Chimney

The masonry chimney must have an approved liner, ceramic

tile, clay or metal. The masonry chimney must be able to

accommodate the spent fuel gasses; consult a venting

HVAC contractor for chimney capacity. A common venting

like-fuel appliance into this lined masonry chimney is

permissible. The chimney’s diameter must be large enough

to adequately draft the spent fuel gasses. A venting HVAC

contractor will be required to spec a chimney system. The

minimum vertical chimney length should be no less than 5

ft (1.5 m); the termination point should extend at least 3

feet (0.9 m) above where the chimney meets the roofline

and at least 2 feet (0.6 m) higher than any vertical wall or

similar obstruction within 10 feet (3.1 m). See Figure C.

C) EXTERIOR masonry Chimney

Refer to the National Fuel Gas Code and consult a local

venting HVAC contractor.