8 6 720 606 804 (02.10)

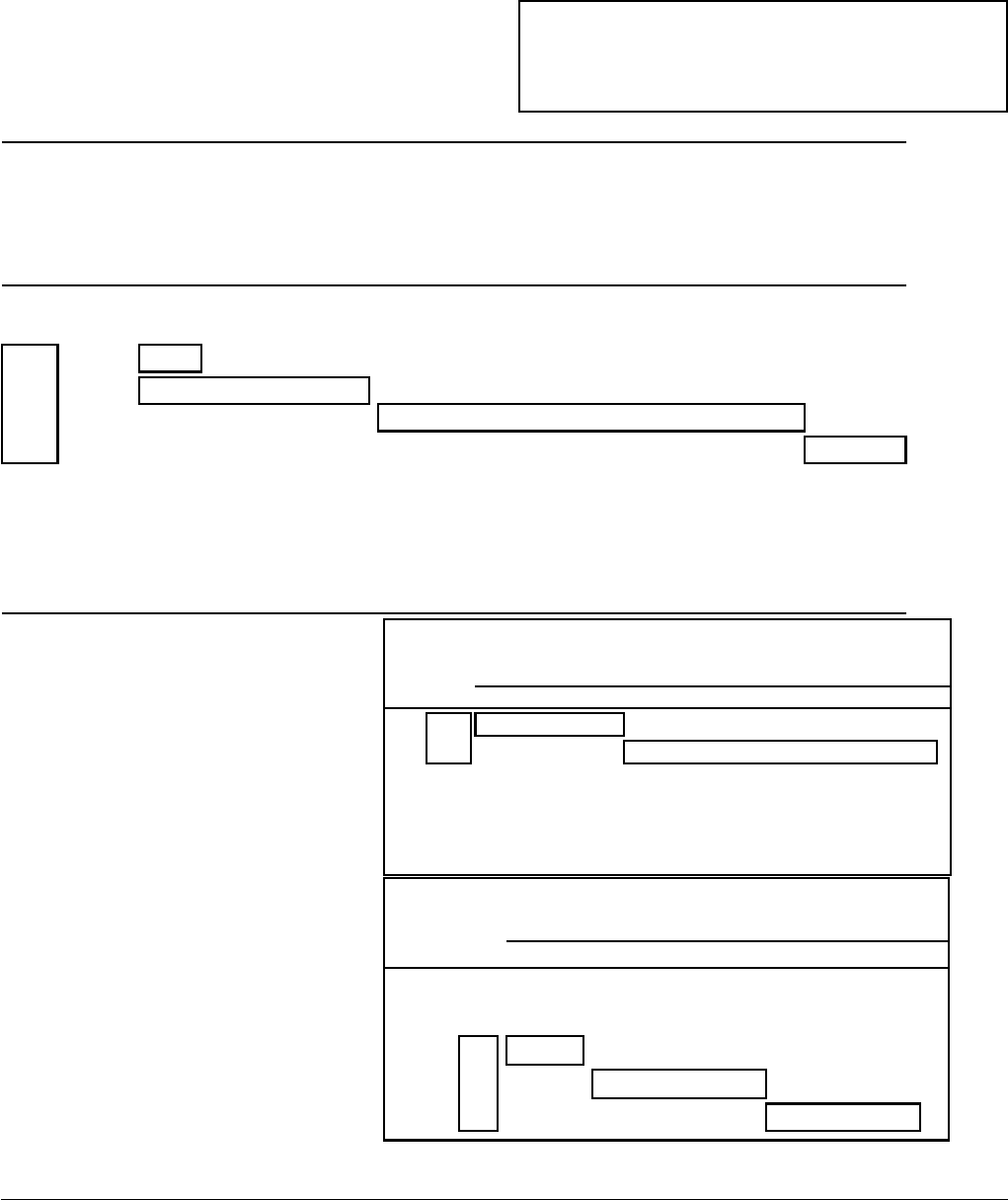

Nominal

Iron Pipe

Black Iron Pipe

Size, Length of Pipe, Feet

Inches 10 20 30 40 50 60 70 80 90 100 125 150

1/2 275 189 152 129 114 103 96 89 83 78 69 63

3/4 567 693 315 267 237 217 196 185 173 162 146 132

1 107 732 590 504 448 409 378 346 322 307 275 252

1 1/4 220 149 121 103 913 834 771 724 677 630 567 511

1 1/2 330 229 185 155 141 127 118 108 102 976 866 787

2 622 433 346 299 264 239 220 204 192 1811 1606 1496

Copper

Outside Length of Tubing, Feet

Diameter,

Inch 10 20 30 40 50 60 70 80 90 100

3/8 39 26 21 19 _ _____

1/2 9262 50 41 37 3531292726

5/8 199 131 107 90 79 72 67 62 59 55

3/4 329 216 181 145 131 121 112 104 95 90

7/8 501 346 277 233 198 187 164 155 146 138

GAS PIPING, CONNECTIONS and Gas Regulator

Before connecting the gas supply, check the rating plate on the right side of the front cover to be sure that the heater is

rated for the same gas to which it will be connected.

In the United States: The installation must conform with local codes or, in the absence of local codes, the National Fuel

Gas Code ANSI Z223.1/NFPA 54.

In Canada: The Installation should conform with CGA B149 INSTALLATION CODES and /or local installation codes.

FOR NATURAL GAS

Maximum Capacity of pipe in Cubic Feet of Gas per Hour

for Gas Pressure of 0.5 Psig or less and a Pressure drop of

0.3 in Water Column.

(Based on a 0.60 Specific Gravity Gas) Btu numbers given

in thousands.

GAS LINE SIZING

The gas supply piping should be sized according to the Applicable Plumbing Code for a maximum draw of 117,000 BTUH. First

determine the effective length of the gas supply line by measuring the actual length of piping, and then adding 5 ft. for every elbow

or “T” to the actual length. Use the charts below to determine the pipe diameter necessary to accommodate the BTU demand

of the unit. If there are more gas drawing appliances on the line, size according to the maximum amount of BTU demand.

Follow boxed numbers for piping just one Aquastar 125HX

(example: 3/4” B.I. Natural Gas pipe for 30 ft. will handle

152,000 btu’s). For multiple appliances combine the total

btu input load and then refer to applicable chart below.

FOR LP GAS

Maximum Capacity of Pipe in Thousands of

BTU per Hour of Undiluted Petroleum Gases

(at 11 inches Water Column Inlet Pressure)

(Based on a Pressure Drop of 0.5 Inch Water

Column).

Maximum Capacity of Semi-Rigid

Tubing in Thousands of BTU per Hour of

Undiluted Liquified Petroleum Gases (at 11

inches Water Column Inlet Pressure)

(Based on a Pressure Drop of 0.5 Inch Water

Column)

* Source National Fuel Gas Code NFPA 54, ANSI Z223.1.

Nominal

Iron Length of Black Iron Pipe, Feet

Pipe Internal

Size, Diameter

inches inches 10 20 30 40 50 60 70 80 90 100 125 150 175 200

1/4 0.364 32 22 18 15 14 12 11 11 10 9 8 8 7 6

3/8 0.493 72 49 40 34 30 27 25 23 22 21 18 17 15 14

1/2 0.622 132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4 0.824 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1 1.049 520 350 285 245 215 195 180 170 160 150 130 120 110 100

1 1/4 1.380 1050 730 590 500 440 400 370 350 320 305 275 250 225 210

1 1/2 1.610 1600 1100 890 760 670 610 560 530 490 460 410 380 350 320

2 2.067 3050 2100 1650 1450 1270 1150 1050 990 930 870 780 710 650 610

2 1/2 2.469 4800 3300 2700 2300 2000 1850 1700 1600 1500 1400 1250 1130 1050 980

3 3.068 8500 5900 4700 4100 3600 3250 3000 2800 2600 2500 2200 2000 1850 1700

4 4.026 17,500 12,000 9,700 8,300 7,400 6,80 6,200 5,800 5,400 5,100 4,500 4,100 3,800 3500