Part No. 800012 Form No. F021402A

Page 9 of 12

OPERATION continued

1616

1616

16

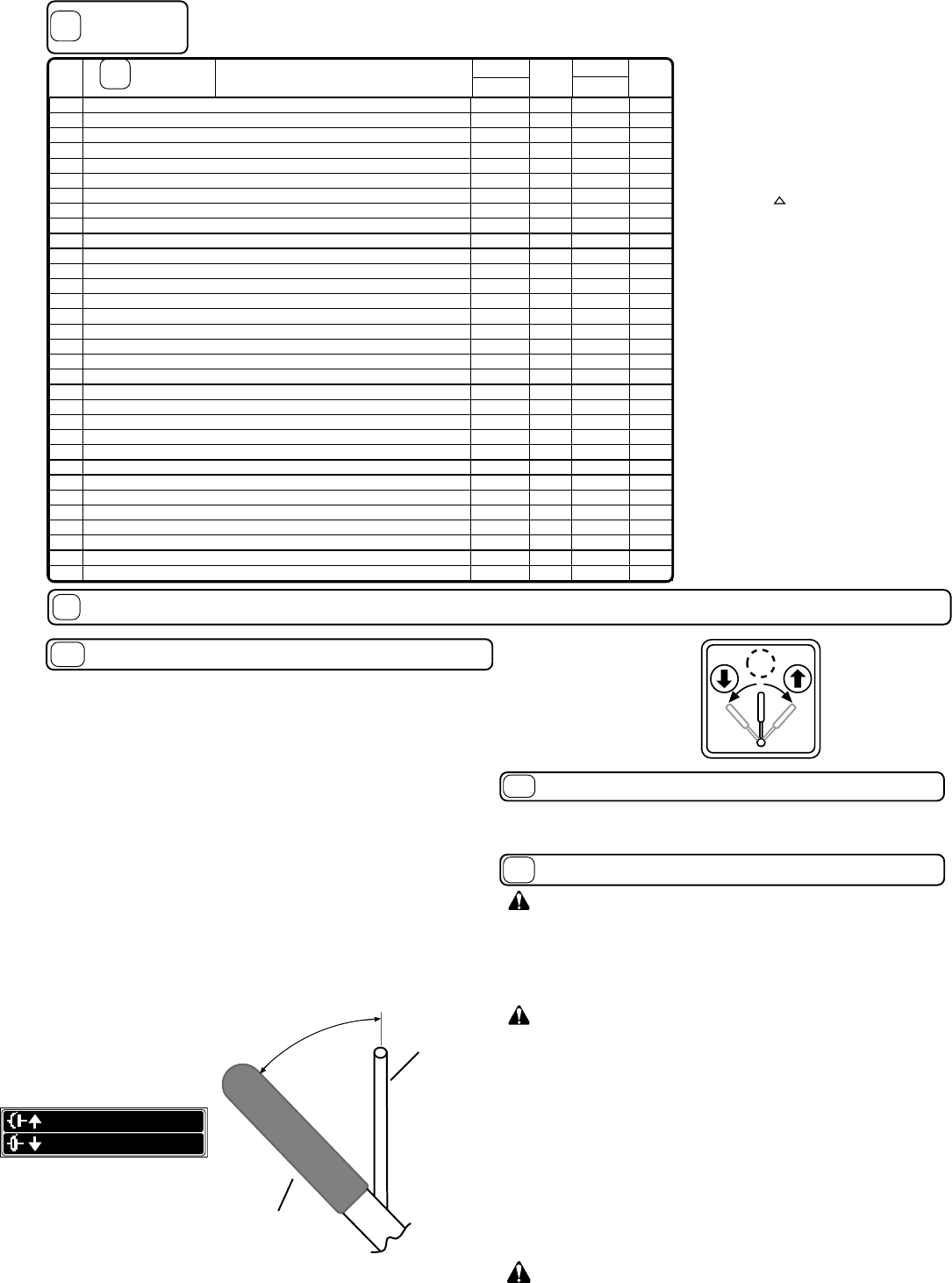

PROPULSION self propelled only

16.616.6

16.616.6

16.6

PROPULSION: BG self-propelled vacuums are equipped

with 1 forward gear, neutral and reverse. With the engine

running, the bail in released position and brake in on

position, select desired drive gear. Lift bail against handle to

engage drive (see figure 1 & 2). Smoothly engage the bail.

Use good judgement when operating the self-propelled

drive.

Using neutral, on level terrain is advisable when maneuver-

ing in tight areas. This increases operator control, and can

prevent bumping into nearby objects.

Do not force-shift gears of transmission. To assist gear

meshing, it may be necessary to partially engage bail while

shifting.

To stop machine, release operator's bail.

For reverse - Set Throttle to Idle.

With operator's bail released, pull shift lever reverse

position. Then smoothly lift operator's bail against handle.

Release bail to stop (see figure 2).

Never store engine indoors or in enclosed poorly venti-

lated areas with fuel in tank, where fuel fumes may reach an

open flame, spark or pilot light, as on a furnace, water heater,

clothes dryer or other gas appliance.

If engine is to be unused for 30 days or more, prepare as

follows:

Be sure engine is cool. Do not smoke. Remove all

gasoline from carburetor and fuel tank to prevent gum deposits

from forming on these parts and causing possible malfunction

of engine. Drain fuel outdoors, into an approved container,

away from open flame. Run engine until fuel tank is empty and

engine runs out of gasoline.

Do not store with debris in bag.

NOTE: Fuel stabilizer (such as Sta-Bil) is an acceptable

alternative in minimizing the formation of fuel gum deposits

during storage. Add stabilizer to gasoline in fuel tank or

storage container. Always follow mix ratio found on stabilizer

container. Run engine at least 10 min. after adding stabilizer to

allow it to reach the carburetor.

Using two people to lift machine is recommended. Lift holding the

handle and front of nozzle. Secure in place during transport.

HANDLING & TRANSPORTING:

16.416.4

16.416.4

16.4

STORAGE

16.516.5

16.516.5

16.5

Bail Down

Disengages

Drive

Handle

Bail

Bail Up

Engages

Drive

Fig. 1

Fig. 2

810207

N

REV FWD

Drive gear

selection

1919

1919

19

PULL TO ENGAGE CLUTCH

RELEASE TO DISENGAGE CLUTCH

830503

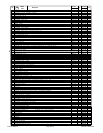

Parts List

continued from

page 11.

PA RT S

LIST

1919

1919

19

Description

85 BRACKET ANGLE SHIFT - - 810158 1

86 CABLE CLUTCH ASS’Y BG - - 810160 1

87 GUARD CHAIN W/LABELS (INLUDES ITEM 51) - - 811041 1

88 ROD BAIL ASS’Y - - 900970 1

89 GRIP --8008851

90 ROD LEVER SHIFT ASS’Y (INCLUDES ITEM 89) - - 810162 1

91

92 CAP ENDS 800392 2 800392 2

93 TY WRAP 900407 3 900407 5

94 CHAIN DRIVE BG - - 810156 1

95 HANDLE BRACE LH 800821 1 800821 1

96 CASTER DUAL ASSY (INCLUDES (1) OF EACH 11, 12, 13, 14) 800682 2 800682 2

97

PROTECTOR WHEEL ASS’Y (INCLUDES ONE EACH OF 21, 19, 18, 53)

800347 2 800347 2

98 LABEL DO NOT FILL WHILE ENGINE IS HOT 400268 1 400268 1

99 HANDLE BRACE RH 800822 1 800822 1

100 LABEL DANGER KEEPS HANDS & FEET AWAY 400424 1 400424 1

101 LABEL CAUTION 830138 2 830138 2

102 LABEL FLYING MATERIAL 810736 1 810736 1

103 LABEL EAR EYE BREATHING 890254 2 890254 2

104 LABEL WARNING GUARDS - - 900327 1

105 LABEL CLUTCH - - 830503 1

106 LABEL READ 890301 1 890301 1

107 GUARD PULLEY BG80 - - 811037 1

108 GUARD BELT BG80 - - 800021 1

109 SCREW SELF TAP 1/4 - 14 X 3/4 - - 900505 2

110 NUT JAM 1/4-20 *8143001 1 *8143001 1

111 BALL 1/4 850194 1 850194 1

112 WASHER BELLVILLE 1/4 850207 2 850207 2

113 PLATE QUAD LIFT 850192 1 850192 1

114 PLATE FRICTION LIFT 850191 1 850191 1

115 BAR LEVER DOOR 850189 1 850189 1

116 PLATE CLAMP LIFT 850193 1 850193 1

Item

No.

BG1002

Part No.

Qty.

Part No.

BG1002SP

Qty.

Denotes parts found in

parts bag assembly.

* Denotes standard hardware

item that may be purchased

locally.