Part No. 800012 Form No. F021402A

BG VACUUM

95

99

5

Page 3 of 12

For your safety and the safety of others, these directions should be followed:

Use of Ear Protection is recommended while

operating this machine.

Do not operate this machine without first reading

owner's manual and engine manufacturer's manual.

Use of Eye and Breathing protection is recom-

mended when using this machine, especially in dry

and dusty conditions. Optional bag cover directs dust

toward ground, away from the operator.

·DO NOT place hands or feet inside nozzle intake opening, near

debris outlet or near any moving parts.

·DO NOT start engine without debris bag and quick discon-

nect connected firmly in place to exhaust outlet.

GENERAL SAFETY

99

99

9

·DO NOT start or operate machine with debris bag zipper open.

·DO NOT operate during excessive vibration.

·DO NOT remove bag until engine has been turned off and has

come to a complete stop.

·DO NOT remove hose kit cap on nozzle until engine has been

turned off and has come to a complete stop.

·DO NOT operate machine with hose cap, bag or hose removed.

·DO NOT use this machine for vacuuming exclusively sand,

dust, fine dirt, rock, glass, string like material, grain, rags,

cans, metal, bark or water.

·DO NOT operate this machine on slopes greater than 20%.

·DO NOT pick up any hot or burning debris, or any toxic or

explosive material.

·DO NOT allow children to operate this equipment.

PUT OIL IN ENGINE BEFORE STARTING.

Read all safety and operating instructions

before assembling or starting this unit.

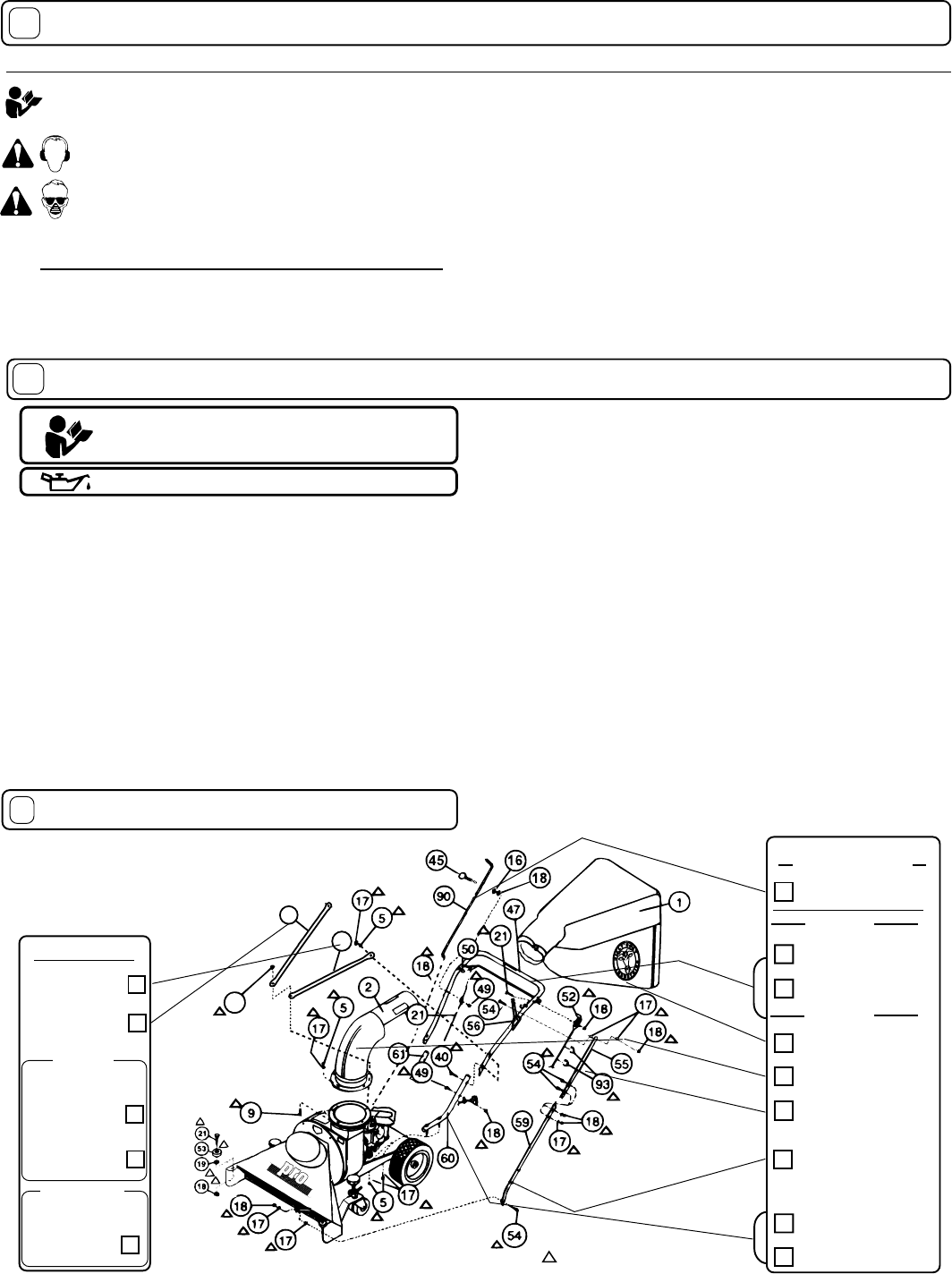

ASSEMBLY

1010

1010

10

Rod Lever

810162

Self Propelled Only

Per Model

Boxing Checklist

Handle Bail Assy

SP

Units Only

810164

Handle Assy

Push

Units Only

800043

All Models

Debris Bag

800730

Elbow Assembly

800967

Check

Check

Check

Check

These items should be included in your carton. If any of

these parts are missing, contact your dealer.

Check

Check

Your Billy Goat is shipped from the factory in one carton, completely assembled

except for the debris bag, upper and lower handles, handle brace, nozzle control

rods, exhaust elbow, gasket, and (sp only) rod lever shift assy.

1 Lower handles: Assemble lower handles (items 60, 61) to engine base using

washers (item 17) and lock nuts (item 5).

HAND TIGHTEN ONLY.

2 Upper Handle, Handle Braces:

2.1 Assemble upper handle (item 47), and handle braces (items95 and 99) to

lower handles using screws (item 40), washers (item 17) and lock nuts (item 5)

with ends of handle brace on inside of handle and screw heads facing inward,

toward debris bag, otherwise premature bag wear could result.

HAND TIGHTEN ONLY.

2.2 After elbow assembly has been installed, attach front of handle braces

(items 95 and 99) to 3/8 inch stud on elbow mounting flange, using lock nut

(item 43).

3. Tighten all handle screws and nuts on lower handles, upper handle and handle

brace.

4. Throttle control (item 52):

4.1 Attach throttle to upper handle using screw (item 21) and lock nut (item 18).

4.2 Attach throttle control conduit to handles using cable clamps (item 93).

Boxing Checklist

Engine Manual

Briggs & Stratton

10 HP Intek

Check

Brace Handle LH

800821

Per Model

Check

Check

Check

Parts Bag & Lit.

Assy.

Check

Handle Lower R.H.

800943

Check

Link 810987

Check

Handle Lower L.H.

800933

BG1002

800014

PACKING CHECK LIST

5. Nozzle door control rods (items 55, 59):

5.1 Attach end of link (item 59) with single hole to nozzle door mounting hole

using screw (item 54), washers (item 17-2 req'd) and lock nut (item 18).

5.2 Assemble link (item 55) to lever assembly (item 56) using screws (item

54), washers (item 17-2 req'd) and lock nuts (item 18).

5.3 Attach link ends (item 59, 55) to each other in 2 holes using screw (item

21), washers (item 17) and lock nut (item 18).

6. Elbow Assembly (item 2):

Attach elbow assembly (item 2) and flange gasket to exhaust outlet of main

unit using screws (item 17) and lock nuts (item 5).

7. Debris Bag (item 1):

7.1 Attach neck of debris bag onto elbow assembly.

SECURELY TIGHTEN BAG NECK STRAP.

7.2 Attach bag hanger clips to bag loops (item 50) preassembled to upper

handle.

8.

SP MODEL ONLY

. Rod Lever Shift Assy.

8.1 Remove eye bolt (item 45), from hardware bag and slide curved end of rod

through eye bolt (item 45).

8.2 Slide curved end of Rod Lever Shift (item 90) through hole in shift bracket

located on rear of transmission so that shift lever end of rod is up. Reinstall

eye bolt (item 45) and hardward through upper handle and clutch cable

mounting bracket.

9. Attach "z" end of cable (item 86) to inside of bracket on rod bail assy (item 88).

10. Connect spark plug wire.

1111

1111

11

BG1002SP

800015

Denotes parts found in

Parts Bag Assembly

(shown on page 4).

Bar Link Upper

811061

Brace Handle RH

800822

Check