Manual 2100-399

Page 4

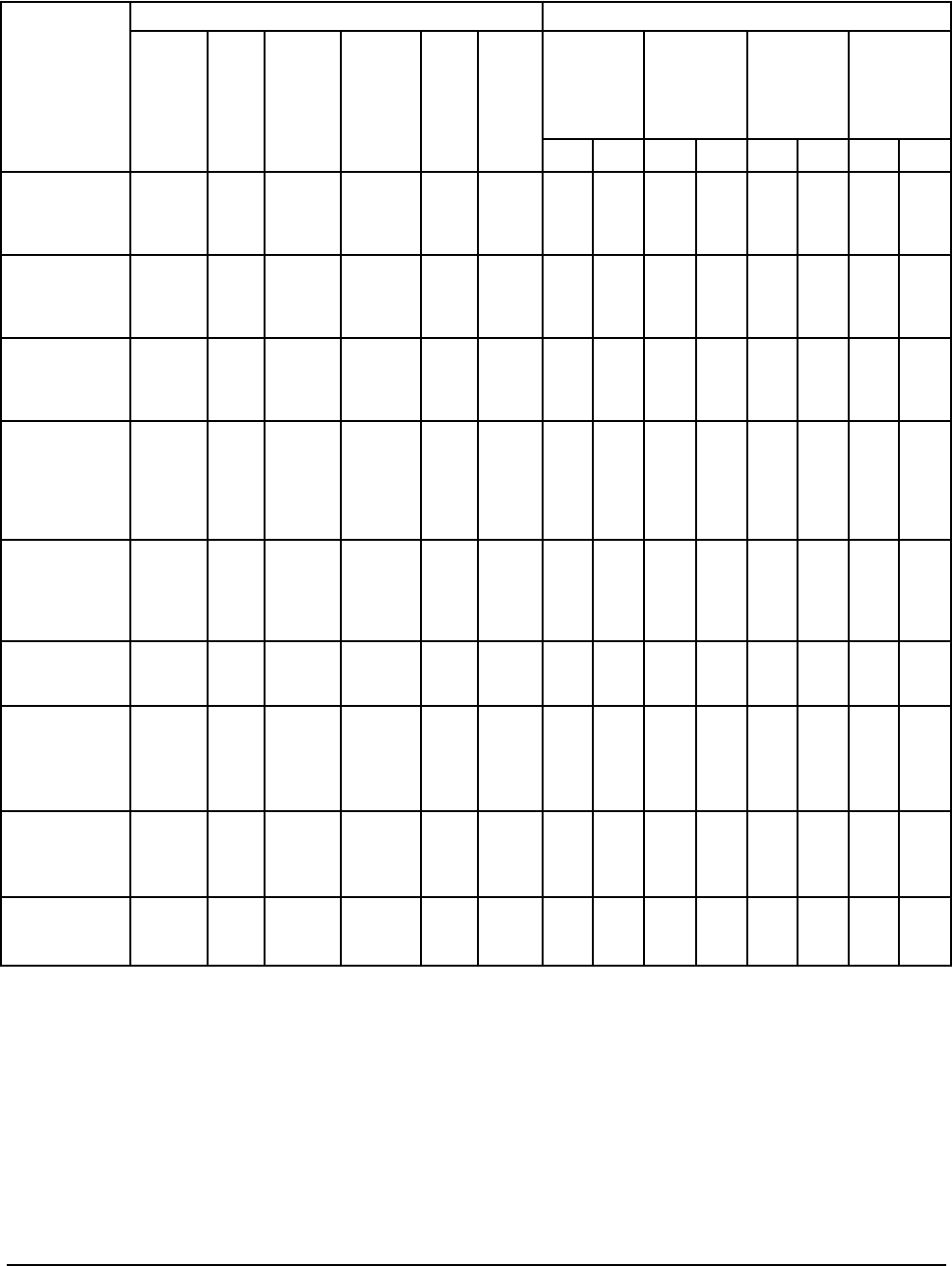

TABLE 2

ELECTRICAL SPECIFICATIONS

ledoM

TIUCRICELGNIS TIUCRICLAUD

detaR

stloV

esahP&

.oN

dleiF

rewoP

.stkC

4

muminiM

tiucriC

yticapmA

1

mumixaM

lanretxE

roesuF

tiucriC

rekaerB

2

dleiF

rewoP

eriW

eziS

2

dnuorG

eriW

eziS

4

muminiM

tiucriC

yticapmA

1

mumixaM

lanretxE

roesuF

rekaerB.tkC

2

rewoPdleiF

eziSeriW

2

eriWdnuorG

eziS

AtkCBtkCAtkCBtkCAtkCBtkCAtkCBtkC

Z0A,00A-124HW

50A

3

01A

51A

1-802/032

1

2ro1

2ro1

2ro1

43

06

68

68

05

07

09

09

8

6

3

3

01

8

8

8

A/N

43

43

43

A/N

62

25

25

A/N

05

05

05

A/N

03

06

06

A/N

8

8

8

A/N

01

6

6

A/N

01

01

01

A/N

01

01

01

Z0B,00B-124HW

60B

3

90B

51B

3-802/032

1

1

1

1

62

44

35

35

53

05

06

06

8

8

6

6

01

01

01

01

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

Z0C,00C-124HW

60C

3

90C

51C

3-064

1

1

1

1

31

32

72

72

02

52

03

03

21

01

01

01

21

01

01

01

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

Z0A,00A-384HW

40A

50A

3

01A

51A

02A

1-802/032

1

1

2ro1

1ro1

2ro1

2ro1

63

75

26

88

88

011

05

06

07

001

001

011

8

6

6

3

3

2

01

8

8

8

8

6

A/N

A/N

63

63

63

95

A/N

A/N

62

25

25

25

A/N

A/N

05

05

05

06

A/N

A/N

03

06

06

06

A/N

A/N

8

8

8

6

A/N

A/N

01

6

6

6

A/N

A/N

01

01

01

01

A/N

A/N

01

01

01

01

Z0B,00B-384HW

60B

3

90B

51B

81B

3-802/032

1

1

1

1

1

52

34

25

25

06

53

05

06

06

06

8

8

6

6

6

01

01

01

01

01

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

Z0C,00C-384HW

3

90C

51C

3-064

1

1

1

31

62

72

51

03

03

41

01

8

41

01

01

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

Z0A,00A-206HW

50A

3

01A

51A

02A

1-802/032

1

2ro1

1ro1

2ro1

2ro1

54

17

79

79

011

06

09

011

011

011

8

4

3

3

2

01

8

6

6

6

A/N

54

54

54

95

A/N

62

25

25

25

A/N

06

06

06

06

A/N

06

06

06

06

A/N

8

8

8

6

A/N

01

6

6

6

A/N

01

01

01

01

A/N

01

01

01

01

Z0B,00B-206HW

3

90B

51B

81B

3-802/032

1

1

1

1

33

06

06

06

54

06

06

06

8

6

6

6

01

01

01

01

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

Z0C,00C-206HW

3

90C

51C

3-064

1

1

1

61

92

92

02

53

53

21

8

8

21

01

01

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

Based on 75°C copper wire. All wiring must conform to NEC and all local codes.

Maximum KW that can operate with heat pump on.

These Minimum Circuit Ampacity" values are to be used for sizing the field power conductors. Refer to the

National Electrical Code (latest version), article 310 for power conductor sizing. CAUTION: When more than one

field power conductor circuit is run through one conduit, the conductors must be derated. Pay special

attention to note 8 of table 310 regarding Ampacity Adjustment Factors when more than 3 conductors are

in a raceway.

T

Q

R

S