Manual 2100-399

Page 11

WIRING — MAIN POWER

Refer to the unit rating plate for wire sizing

information and maximum fuse or “HACR" type

circuit breaker size. Each outdoor unit is marked

with a “Minimum Circuit Ampacity”. This means

that the field wiring used must be sized to carry

that amount of current. Depending on the installed

KW of electric heat, there may be two field power

circuits required. If this is the case, the unit serial

plate will so indicate. All models are suitable only

for connection with copper wire. Each unit and/or

wiring diagram will be marked “Use Copper

Conductors Only”. These instructions must be

adhered to. Refer to the National Electrical Code

(NEC) for complete current carrying capacity data

on the various insulation grades of wiring material.

All wiring must conform to NEC and all local

codes.

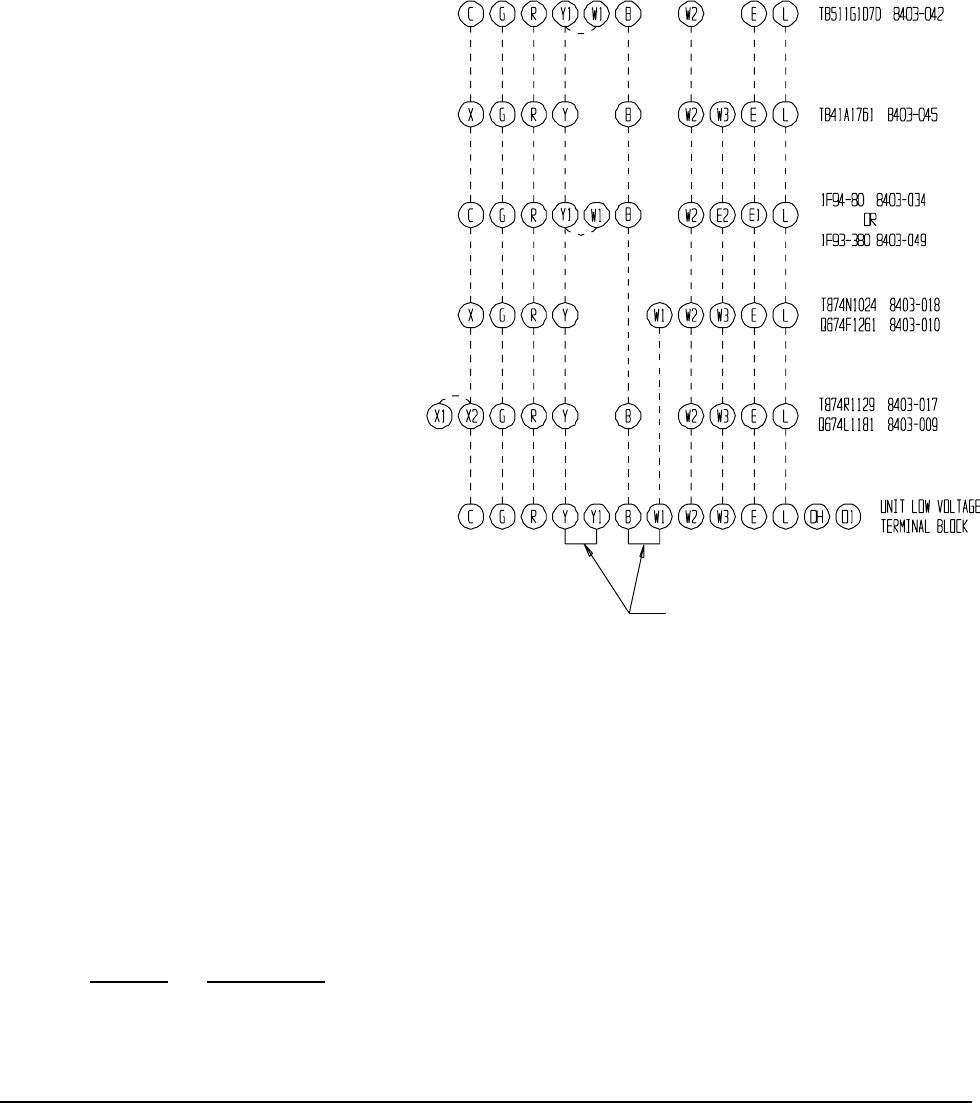

Nine (9) wires should be run from thermostat subbase to

the 24V terminal board in the unit. A nine conductor, 18

gauge copper, color-coded thermostat cable is

recommended. The connection points are shown in

Figure 7.

IMPORTANT NOTE:

Only the thermostat and subbase combinations as shown at

the right will work with this equipment. The thermostat and

subbase must be matched and the correct operation can be

assured only by proper selection and application of these

parts.

Note 1: 1F93-380 thermostat must be set to "Heat Pump"

mode to operate properly.

Press the program"RUN" button to make sure the

thermostat is in run program model.

Press time "FWD" and "BACK" at the same time to

enter User Configuration Menu.

Press and hold set "TIME" and "DAY" for about

3 seconds to enter Installer Menu.

The thermostat will display "MULTI STG"

Press the "UP" or "DOWN" button until the display

reads "HEAT PUMP"

Press program "RUN" button to resume operation.

NOTE:The voltage should be measured at the field power

connection point in the unit and while the unit is

operating at full load (maximum amperage

operating condition).

The electrical data lists fuse and wire sizes

(75ºC copper) for all models, including the

most commonly used heater sizes. Also shown

are the number of field power circuits required

for the various models with heaters.

The unit rating plate lists a “Maximum Time

Delay Relay Fuse” or “HACR" type circuit

breaker that is to be used with the equipment.

The correct size must be used for proper circuit

protection and also to assure that there will be

no nuisance tripping due to the momentary high

starting current of the compressor motor.

The disconnect access door on this unit may be

locked to prevent unauthorized access to the

disconnect. To convert for the locking

capability, bend the tab located in the bottom

left hand corner of the disconnect opening

under the disconnect access panel straight out.

This tab will now line up with the slot in the

door. When shut, a padlock may be placed

through the hole in the tab preventing entry.

See Start-up section for information on three

phase scroll compressor start-ups.

WIRING — LOW VOLTAGE WIRING

230/208V, 1 phase and 3 phase equipment dual

primary voltage transformers. All equipment

leaves the factory wired on 240V tap. For 208V

operation, reconnect from 240V to 208V tap.

The acceptable operating voltage range for the

240 and 208V taps are:

paTegnaR

042

802

612-352

781-022

MIS-440

FIGURE 7

UNIT 24V TERMINAL BOARD

See Note 1

FACTORY JUMPER