4

THERMOSTAT INSTALLATION (MODEL 2H2C)

FURNACE - MODEL 2540 MUST USE THIS THERMOSTAT

The thermostat is very sensitive. HANDLE WITH CARE AT ALL TIMES.

Locate thermostat 48˝ to 54˝ above floor on an INTERIOR wall. Pick a dry

area where air circulation is good. EXTERIOR wall location must have a

3/4˝ spacer between thermostat and exterior wall.

1. Be sure all electrical power has been disconnected from the air con-

ditioner, furnace and the power supply.

2. Do not install the thermostat where there are unusual heating condi-

tions: such as direct sunlight, heat producing appliances (television,

radio, wall lamp, etc.) or a furnace or air conditioner supply register.

3.

ATTACHING THE WALL THERMOSTAT. Separate the thermostat body from the

sub-base by gently squeezing the top and bottom. Pull wires through

access hole in base plate. Attach thermostat sub-base to the wall at

the desired mounting location. Mount the sub-base to the wall before

connecting the wires. See instruction provided with thermostat.

SYSTEM CHECKS

ƽ WARNING

FIRE OR EXPLOSION

• Never check for leaks with an open flame.

DIAGNOSTIC CHART

A diagnostic LED is located inside the exterior access cover on the out-

side edge of the horizontal (2) stage control board. The following

graph defines the codes.

NUMBER OF LED FLASHES DIANOSTIC INFORMATION LOCKOUT

1 Low Input voltage SOFT

2 Ignition Failure SOFT

3 Open High Limit SOFT

4 Stuck Sail Switch HARD

5 Module Fault HARD

NOTE:A SOFT lockout is a condition that is timed and will make addition-

al attempts to correct the problem. A HARD lockout requires reset

of the thermostat or turning the power switch off then back on.

PROPANE GAS PRESSURE TEST

The furnace and any individual shut-off valve must be disconnected

from gas supply piping system during any pressure testing of system

at test pressures of more than 1/2 PSI.

Before furnace is connected piping systems must be tested to be leak

free. The test must maintain air pressure of at least 6˝ of mercury or 3

PSI for at least 10 minutes.

The entire piping system must be maintained within a range of 10-14˝

W.C. when all appliances are in operation. Test gas connections for

leakage with a leak test solution.

STATIC PRESSURE TEST

CASING STATIC PRESSURE TABLE

If duct static pressure cannot be set, casing static pressure should not exceed

the values listed below when taken cold.

DUCTING SYSTEM OPERATING VOLTS FLEXIBLE HARD

DC MODELS 12 0.25˝ W.C. 0.35˝ W.C.

Voltage greater than indicated will cause higher static readings.

Reducing the number of duct turns and stretching ducts will increase

air flow and reduce static pressure. Adding ducts or increasing dis-

charge system (hard ducting) will also reduce static pressure. NOTE:

Special tool required to take casing static pressures.

Location for Static Pressure Tap for casing is on the back of casing

(top left corner) (

FIG 3).

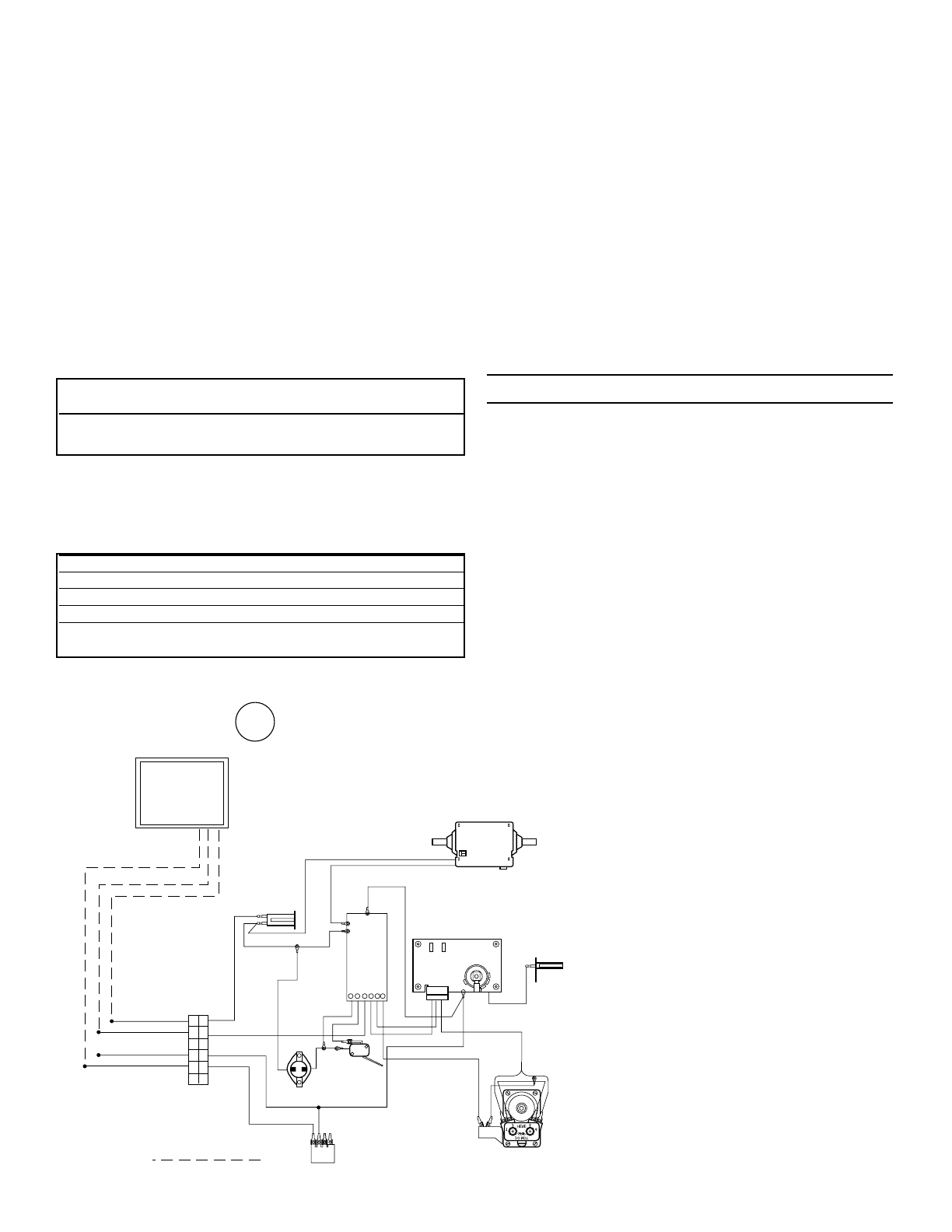

VALVE

MOTOR

IGNITION

CONTROL

SAIL

SWITCH

+12 VDC

-12 VDC

YELLOW

LIMIT

SWITCH

BULK HEAD

CONNECTOR

DUAL

CONTROL

WHITE

YELLOW

YELLOW

BLUE

ORANGE

BROWN

BLACK

BLACK

BLUE

RED

RED

HIGH TENSION

CHASSIS

GROUND

CHASSIS

GROUND

ELECTRODE

RED

RED

WHITE

GREEN

+THERMO

-THERMO

ELECTRONIC

DIGITAL

THERMOSTAT

1

1

1

22

2

3

3

3

4

4

4

5

5

5

66

6

CUSTOMER SUPPLIED WIRE

IMPORTANT: If any original wire has to

be replaced, it must be replaced with

type 105˚C or it's equivalent.

2-STAGE - MODEL 2540

WIRING

4