19

installation

Warning

The exhaust gas ducts must not be in contact with or close

to in ammable material and must not pass through building

structures or walls made of in ammable material.

When replacing an old appliance, the ue system must be

changed.

Important

Ensure that the ue is not blocked.

Ensure that the ue is supported and assembled in accordance

with these instructions.

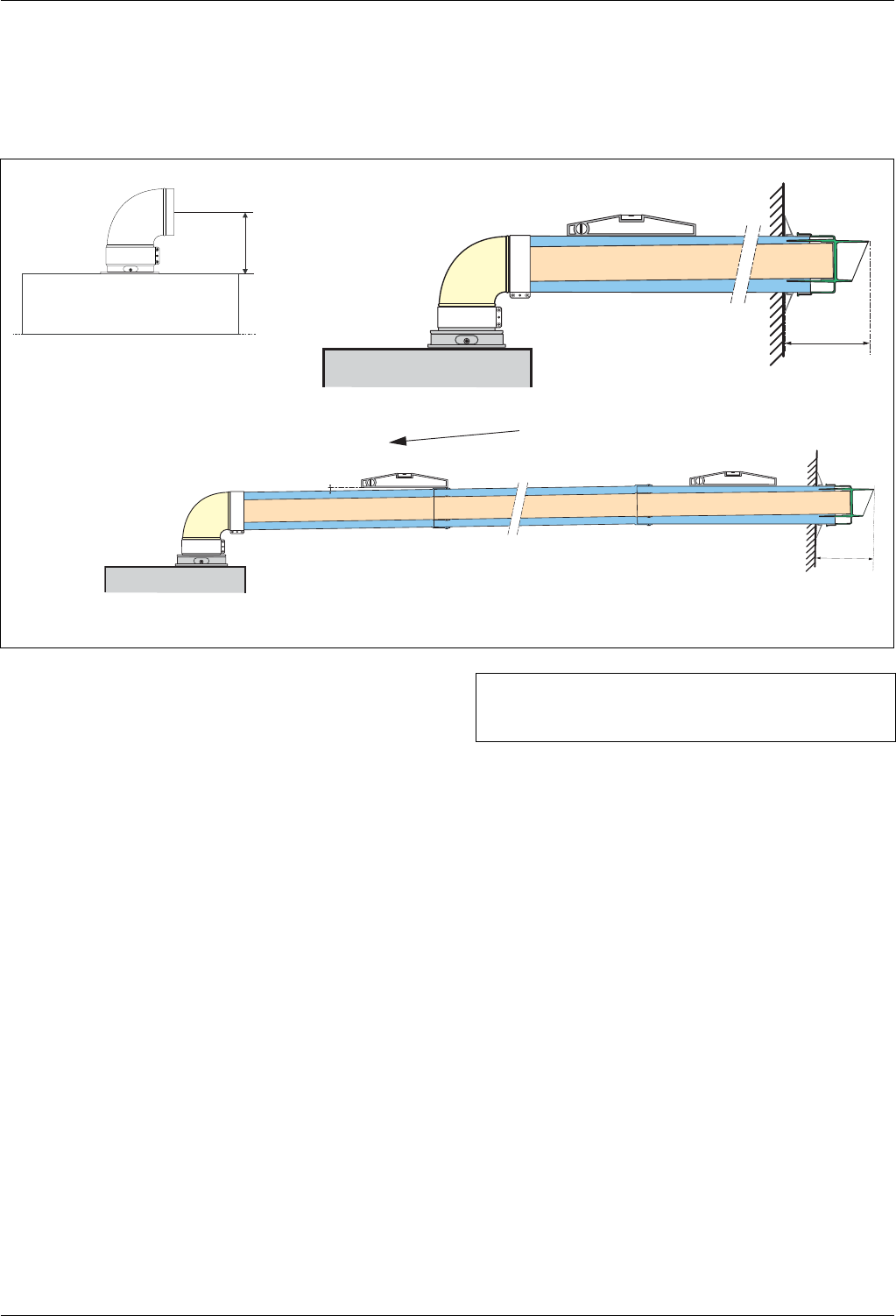

150 mm

118

* Min slope: 1˚

1˚= 17.5mm per metre

150 mm

* pente

Installation without extension

Installation with extension

Level

Level

Fitting the Coaxial Flue (Ø 60 / 100 Horizontal)

Contents:

1x Silicone O-Ring (60mm)

1x Elbow (90°)

2x Wall Seals (Internal & External)

1x Flue Pipe including Terminal (1 metre - 60/100)

2x Flue Clamps

4x Screws

2x Seals

Once the boiler has been positioned on the wall, t the rubber

ue seal into the internal ue turret (see diagram opposite),

Insert the elbow into the socket and rotate to the required

position. note: It is possible to rotate the elbow 360° on its vertical

axis.

Using the ue clamp, seals and screws supplied (Fig 4) secure the

elbow to the boiler.

The 1 metre horizontal ue kit (3318073) supplied is suitable for

an exact X dimension of 753mm.

Measure the distance from the face of the external wall to the face

of the ue elbow (X - Fig 2), this gure must now be subtracted

from 753mm, you now have the total amount to be cut from the

plain end of the ue.

Draw a circle around the outer ue and cut the ue to the required

length taking care not to cut the inner ue, next cut the inner

ue ensuring that the length between the inner and outer ue is

maintained. (Fig 4).

e.g.

X = 555mm

753-555 = 198mm (Length to be cut from the plain end of the

ue).

Once cut to the required length, ensure that the ue is free from

burrs and reassemble the ue. If tting the ue from inside of

the building attach the outer wall seal to the ue terminal and

push the ue through the hole, once the wall seal has passed

through the hole, pull the ue back until the seal is ush with the

wall. Alternatively, the ue can be installed from outside of the

building, the outer seal being tted last.

Should the ue require extending, the ue connections are push

t, however, one ue bracket should be used to secure each metre

of ue.

Note: See table for maximum and minimum ue runs.

slope

Fig. 3

Note: A Plume management kit is available for 60/100

horizontal termination. Instructions for installation are

supplied with the Plume management kit.