36

commissioning

Operation 4 - Checking the CO2 at minimum gas ow

With the Test function active,

rotate the encoder

to select

the icom

and . The

boiler is forced to the minimum

power.

Wait 1 minute for the boiler to

stabilise before carrying out the

combustion analyses.

If the

CO2 value (%) read di ers

by 0.5 % from the value found, then adjust the gas valve following

the instructions below, otherwise move directly onto operation 5.

Adjusting the gas valve to minimum gas ow

Remove

cap and adjust screw 2 by turning anti-clockwise in

increments to reduce the CO2 level. Wait 1 minute after each

adjustment for the CO2

value to stabilise.

WARNING! this adjustment

is sensitive: a rotation of a 1

turn corresponds to 0.2% of

CO2.

If the value measured

corresponds to the

value given in the table,

adjustment is complete,

otherwise start the setting

procedure again.

Attention! If the value of the CO2 at the minum power has been

changed, it is necessary repet the adjusting at maximum gas

ow.

Operation 5 - Ending the adjustment

Exit cleaning mode by pressing RESET.

Stop the draw-o .

Verify and repair any leaks of gas.

Re t the front panel to the device.

Re t the blanking cover at combustion test point.

menu 2 - Boiler parameters

submenu 3 - parameter 1 Maximum Heating Power adjustment

submenu 2 - parameter 0

Soft light Ignition

submenu 3 - parameter 5 Heating ignition delay

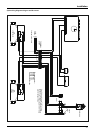

Maximum Heating Power adjustment

The maximum heating power can be adjusted to between the

maximum power allowed by the boiler and the minimum power).

The display shows the value between 100% (“100” on the display)

and 0% (“0”) of this interval.

To check the maximum heating power, access menu 2/sub menu

3/parameter 1, check the value and, if necessary, modify it as

indicated in the Gas Regulation table below. (See page 40 for more

details).

Checking slow ignition power

The soft light can be adjusted between the maximum power

(shown on the display as “100”, i.e. 100%) and the minimum power

(shown on the display as “1”, i.e. 1%).

To check the slow ignition power, access menu 2/sub menu 2/

parameter 0.

Heating ignition delay adjustment

This parameter – menu 2/sub menu 3/parameter 5 - can be used

to manually (0) or automatically (1) set the delay time before the

subsequent reignition of the burner after it has switched o on

reaching the desired temperature in central heating mode.

By selecting manual, it is possible to set the delay in minutes using

the successive parameter (menu 2/sub menu 3/parameter 6), to a

time between 0 and 7 minutes.

Automatic selection means that the boiler will establish the delay

time based on the set-point temperature

Converting the appliance from Natural gas to LPG

These appliances are designed to operate with di erent gas types.

The appliance must only be converted for use with a di erent gas

type by a Gas Safe Registered installer.

To convert the appliance to LPG:

(use these instructions in conjunction with the Instruction sheet

supplied with the LPG Kit).

1. Electrically isolate the appliance

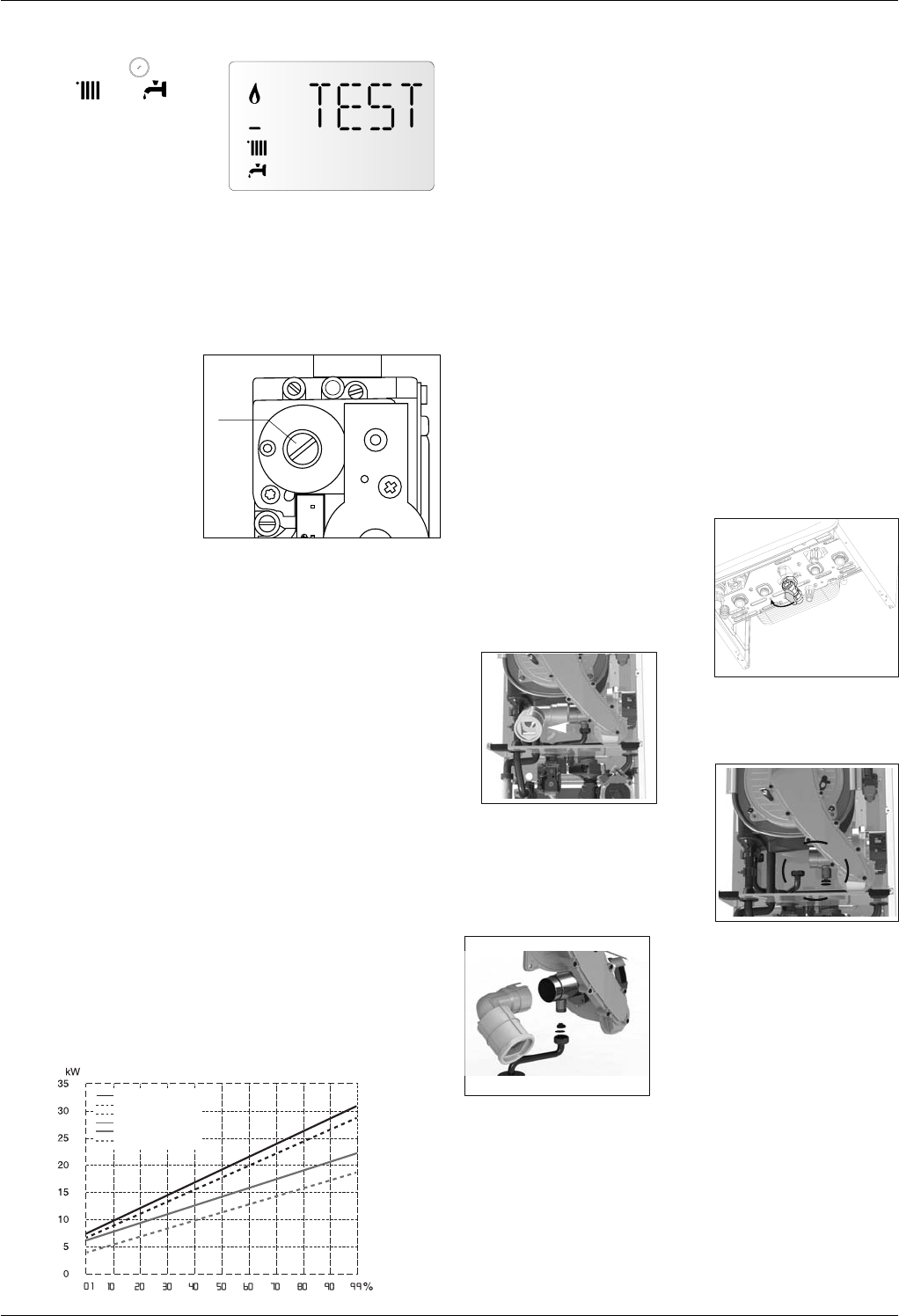

2. Turn o the gas supply ( g 1)

3. Remove the outer case, lower the

front control panel and remove

the front combustion chamber

panel.

4. Remove the green silencer ( g 2)

5. Disconnect the gas supply from

the venturi assembly ( g 3)

6. Inset the correct diaphragm

(depending on the output of the

appliance) into the venturi spigot

7. Reassemble the gas supply onto

the venture assembly ( g 4)

8. Turn on gas supply and test for

tightness

9. Purge gas supply

10. Turn the electrical supply on to

the appliance.

11.Commission the appliance, check the working pressure is

adequate then test and adjust the CO values at maximum and

minimum output described in the commissioning section of the

appliance installation instructions. Ensure the ue gas analyser

used is calibrated and set for the gas group the appliance is

being adjusted for.

12. Check the appliance for gas leaks using gas leak detection uid.

13. A x the label to the appliance that is supplied with the

conversion kit.

CLAS HE EVO 38

CLAS HE EVO 30

CLAS HE EVO SYSTEM 30

CLAS HE EVO 24

CLAS HE EVO SYSTEM 24

CLAS HE EVO SYSTEM 18

1

2

3

4