7

User Manual

Anti-frost Device.

When the electrical supply is turned on, the anti-frost function acts

on the central heating ow temperature probe, independently from

other safety devices.

If the primary circuit temperature is between 3°C and 8°C the

pump will run (with the diverter valve switching between central

heating and hot water every 1 minute) until the temperature

reaches > 9°C.

If the ow temperature remains between 3°C and 8°C the pump will

continue to run for a maximum of 20 minutes unless a temperature

above > 9°C is detected in the central heating ow, after this the

burner will re (heating position) until a temperature of > 30°C is

detected.

If the central heating ow temperature is < 3°C, the burner will re

(heating position) at minimum power until the temperature reaches

> 30°C, the burner will go out.

If lockout is caused by overheat the burner will not re but the pump

will continue to run (heating position).

The anti-frost device activates only when (with the boiler operating

correctly):

- the system pressure is correct;

- the boiler is electrically powered;

- there is a supply of gas.

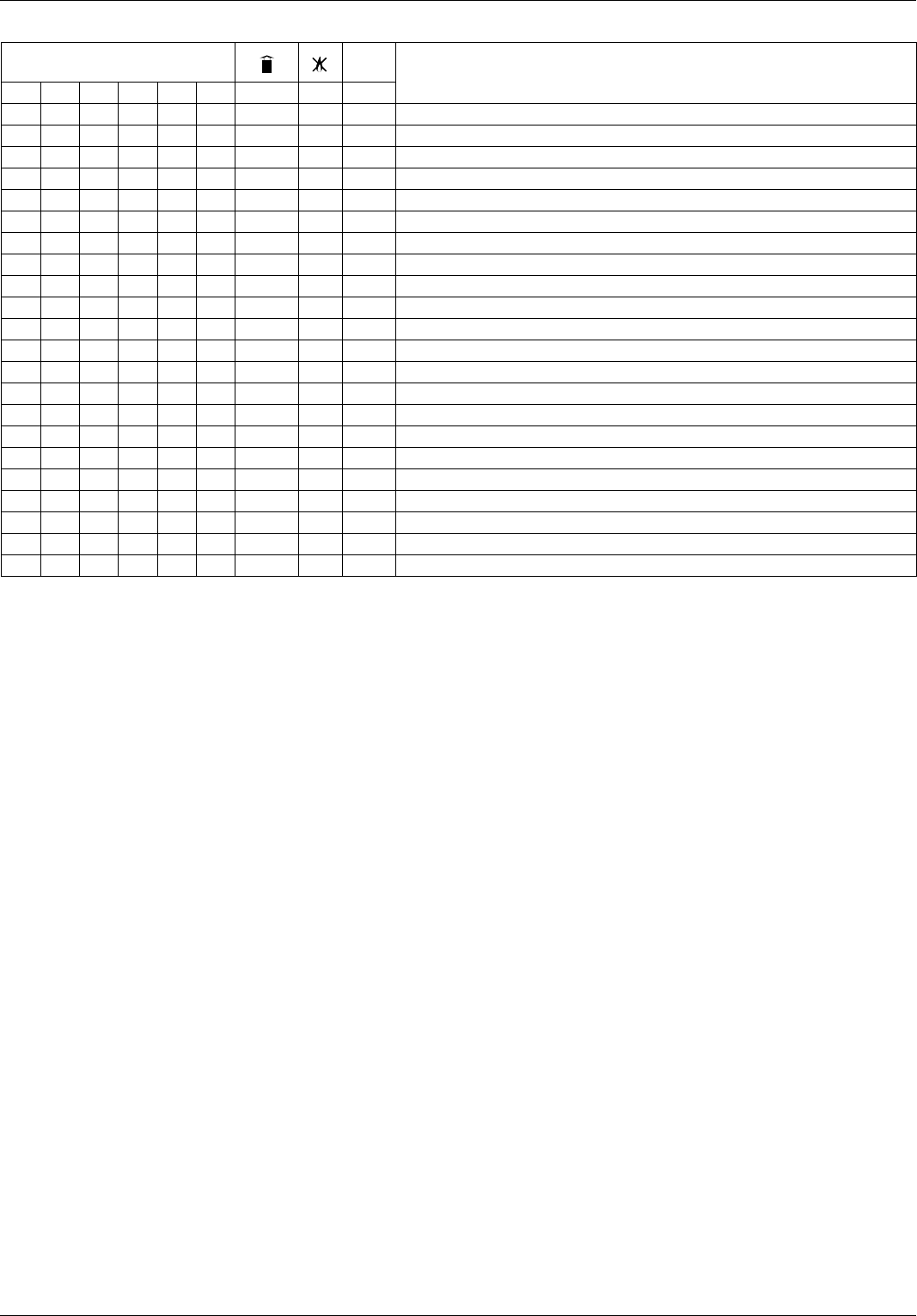

Table summarising error codes

Green Leds

Temperature indicator

Reset

Note

Description ❍ = flashing light

● = lit

40 50 60 70 80 90 yellow red

● ●

X Overheat

●● ●

X Insu cient circulation

●● ●

Insu cient water (request lling)

●● ●

C.H. Flow temp. probe circuit open / short circuit

●● ●

C.H. Return temp. probe circuit open / short circuit

●● ●

External sensor circuit open / short circuit

●● ●

Floor thermostat contact open

●● ●

X Heating delivery probe problem

●● ●

Insu cient circulation

● ●

EEPROM error

● ●

Communication error

●●●●● ●

Too many (> 5) resets in 15 minutes

● ●

X Main P.C.B. error

●● ●

Room sensor circuit open / short circuit

●

X No ame detected

●●● ●

Flame detected with gas valve closed

●●● ●

X Flame lift

●●● ●

1st Ignition Failed

●● ● ●

2nd Ignition Failed

●●● ●

Flame cut-o

●● ●

X Thermofuse open

●● ●

X Fan speed error

Change of gas type

Our boilers are designed to function either with Natural Gas (meth-

ane) or L.P.G. gas. If you need to change from one gas to the other,

one of our Authorised Service Centres must be contacted to convert

the appliance.

Maintenance

Schedule an annual maintenance check-up for the boiler with a com-

petent person.

Correct maintenance generally results in savings in the cost of run-

ning the system.

Failure to arrange an annual service for the appliance will invalidate

the second year of the manufacturer’s guarantee.