It is recommended that the following inspections be carried out on the boiler at

least once a year:

1 - Check the seals for the water connections; replace any faulty seals.

2 - Check the gas seals; replace any faulty gas seals.

3 - Visual check of the entire unit.

4 - Visual check of the combustion process or analysis of combustion by-products

(see section 4.5) and cleaning of the burner if needed.

5 - If called for by point. 3, dismantling and cleaning of the combustion chamber.

6 - If called for by point. 4, dismantling and cleaning of the burner jets.

7 - Visual check of the primary heat exchanger:

- check for overheating in the blade assembly;

- clean the exhaust fan if needed.

8 - Adjustment of the flow rate of the gas: flow rate for lighting, partial load and full load.

9 - Check of the heating safety systems:

- safety device for maximum temperature (overheat thermostat);

- safety device for maximum pressure (safety valve).

10- Check of the gas safety systems:

- safety device for lack of gas or flame ionisation (detection electrode);

- safety device for gas cock.

11- Check of the electrical connection (make sure it complies with the instructions

in the manual).

12- General check of the combustion by-products of the discharge/ventilation system.

13- Check of the general performance of the unit.

6. MAINTENANCE

19

The boiler can be converted to use either methane (natural) gas (G20)

or LPG (G30 - G31) by an Authorised Service Centre.

The operations that must be performed are the following:

1. Replace the jets on the main burner (see table in section 5);

2. Pay attention to put the gas restrictor if convert the boiler from NG to

GPL and to take it out when pass from LPG to NG;

2. Adjust the maximum and minimum thermal capacity values for the boiler

(see table in section 5);

3. Replace the gas rating plate;

4. Adjust the maximum thermal power setting;

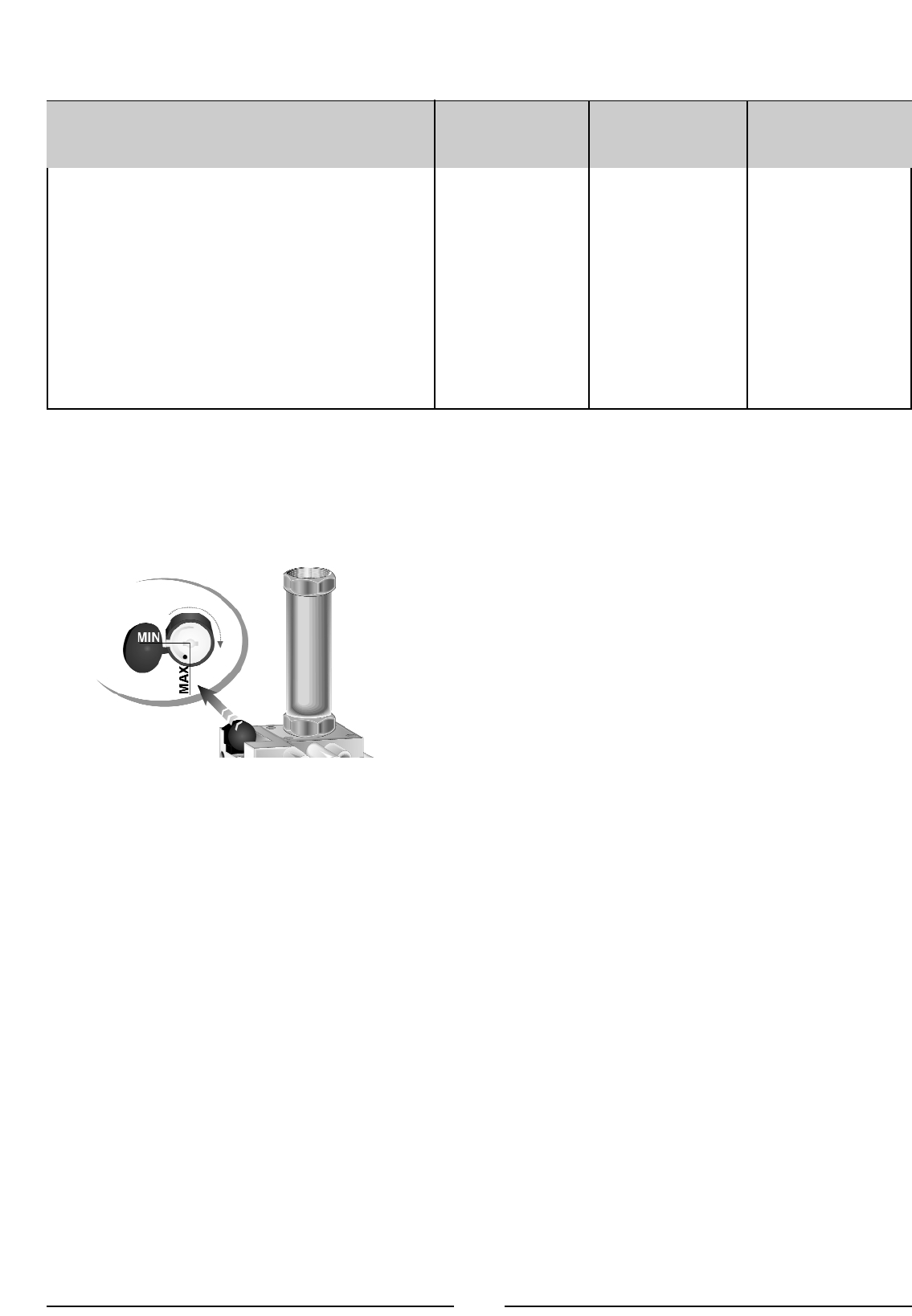

5. Adjust the soft-light feature (open the cover of the regulation screw on the

gas valve (see F

IG. 5.1). Rotate clockwise from min. to max. as per

installation requirements).

5.1 C

HANGING THE

TYPE OF GAS

The outlet pressure of the gas cock is obtained by completely loosening the screw on the solenoid.The

maximum pressure of the gas to the burner will be equal to the nominal delivery pressure minus the

head loss within the gas valve.

[1 mbar = 10,197 mmc.a.]

5. GAS ADJUSTMENTS

Lower Wobbe Index (15°C;1013mbar) MJ/m

3

h

Nominal Delivery Pressure mbar

Minimum Delivery Pressure mbar

15 RFFI

Main Burner: n. 8 jets (ø)mm

Restrictor ø

Consumption (15°C; 1013mbar) m

3

/h

Consumption (15°C; 1013mbar) Kg/h

Gas Burner Pressure:

max - min mbar

CATEGORY II2H3+ Methane Gas

G20

Liquid Butane Gas

G30

Liquid Propane Gas

G31

45.67

20

17

1.30

---

1.62

----

8.5

80.58

29

20

0.77

3.3

----

1.21

22.1

80.58

37

25

0.77

3.3

----

1.19

28.8

VG002Ab

TABLE 5.1

F

IG. 5.1