A. MINERAL TANK: Fiberglass tank with Polyethylene Inner

Shell and Fiberglass Roving Manufactured to Operate at

150 psi. NSF Approved.

B. DISTRIBUTOR SYSTEM: Two-Inch Hub & Lateral Dis

-

tributor for Maximum Service Flow and Minimal Pressure

Loss.

C. MINERAL: High Capacity Ion Exchange Resin. Uniform

and stable beads assure long life, high salt efciency, and

maximum hardness removal.

D. UNDERBEDDING: Multi-Layered Gravel Underbedding

assures full usage of mineral bed and allows for a smooth

and constant water ow for service and regeneration.

E. BRINE TANK: Rotationally Molded Polyethylene with

Dust-Tight Cover.

F. GRID PLATE: Grid plate allows for dry salt storage. Avail

-

able in various sizes and heights.

G. OPTIONAL SAFETY BRINE VALVE: Acts as a Secondary

Shut-Off for Timed Brine and may be used as a Primary

Shut-Off without Timed Brine.

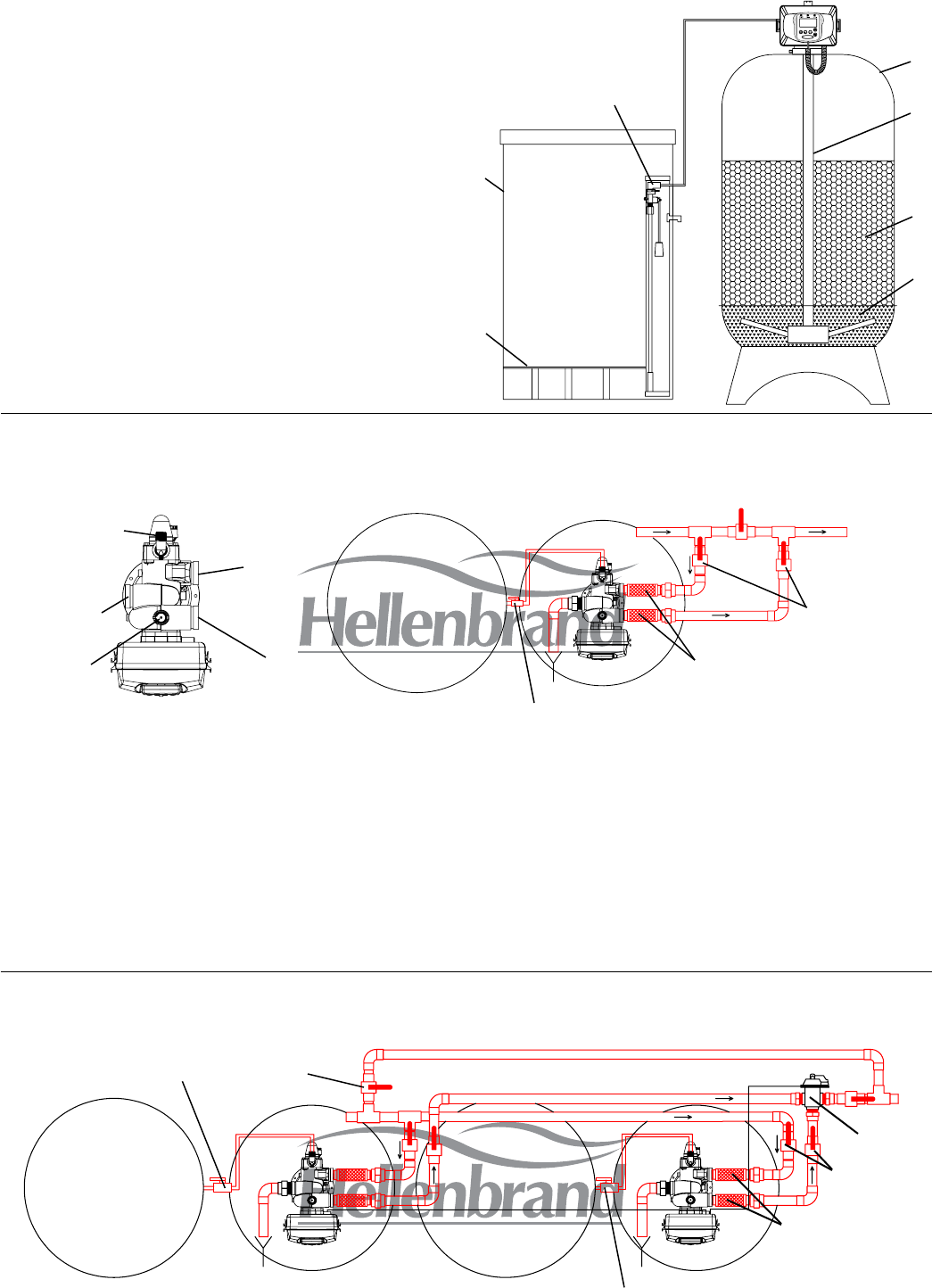

H200 Series

H200 Typical Single Tank Installation-Top Mount

H200 Twin Alternating Tank Installation - Top Mount

A

B

C

D

E

F

G

NOTE:

System connections to the tank must accommodate longitudinal movement between side, top and bottom

openings, exibility in piping or ex connectors are recommended.

Red colored piping, ttings, and connectors are for reference only and are not included. Must be furnished

by others.

Union type connectors are recommended on the inlet and outlet connections.

1" Brine Line must be hard-piped, secured and supported for proper operation. CPVC or Schedule 80 PVC

recommended.

See NOTE Figure 2

Brine Tank(s)

Bypass Valve

Inlet

Outlet

MAV Valve*

Isolation Valves

Flex Connectors

MAV = Motorized Alternating Valve.

Figure 1

Figure 2

Figure 3

Brine Tank

1" MNPT

Brine Line

2” FNPT Inlet &

2.5” Victaulic

2” FNPT Outlet &

2.5” Victaulic

2” FNPT Drain &

2.5” Victaulic

Internal Meter

Outlet

Isolation Valves

Flex Connectors

Bypass Valve

Inlet

Brine Tank(s)

Shut-Off Valve

Shut-Off Valve

Shut-Off Valve

8