10 6 720 606 446

Connecting the pressure relief valve (PRV)

A listed pressure relief valve supplied with the heater must

be installed at the time of installation. Should a discharge

line be added to the PRV no valve is to be placed between

the PRV and the heater. No reducing coupling or other

restriction may be installed in the discharge line. The

discharge line must be installed such that it allows complete

drainage of both the PRV and the line. The location of the

PRV must be readily accessible for servicing or replacement.,

and be mounted as close to the water heater as possible

See Fig 4. To install the PRV, a suitable fitting connected to

an extension on a “T” fitting can be sweated to the hot

water line.

National Fuel Gas Code requires that a sediment trap (drip

leg) be installed on gas appliances not so equipped. The

drip leg must be accessible and not subject to freezing

conditions. Install in accordance with the recommendations

of the serving gas supplier.

WARNING: The heater and its individual shutoff

valve must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 0.5 psig.

The water heater must be isolated from the gas supply piping

system by closing the manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or more than 0.5 psig.

The water heater, including the pressure regulator provided

with it, must not be operated at gas supply pressures in

excess of 0.5 psig. If overpressure has occurred, such as

through improper testing of the gas lines or malfunction of

the supply system, the gas valve and regulator must be

checked for safe operation.

Make sure that the regulator vent is protected against

blockage.

When your connections are made, check for gas leaks at

all joints (not just the ones you made). Apply some soapy

water to all gas fittings and gas valve. Soap bubbles are a

sign of a leak.

NOTE: Do not apply soap solution to pilot filter screen or

pilot orifice area. If you have a leak, shut off the gas. After

verifying that required gaskets are in place, tighten

appropriate fittings to stop leak. Turn the gas on and check

again with a soapy solution. Never test for gas leaks using

a match or flame.

MAXIMUM INLET GAS FLOW PRESSURE SETTING

Above 4.500 ft consult your local gas supplier.

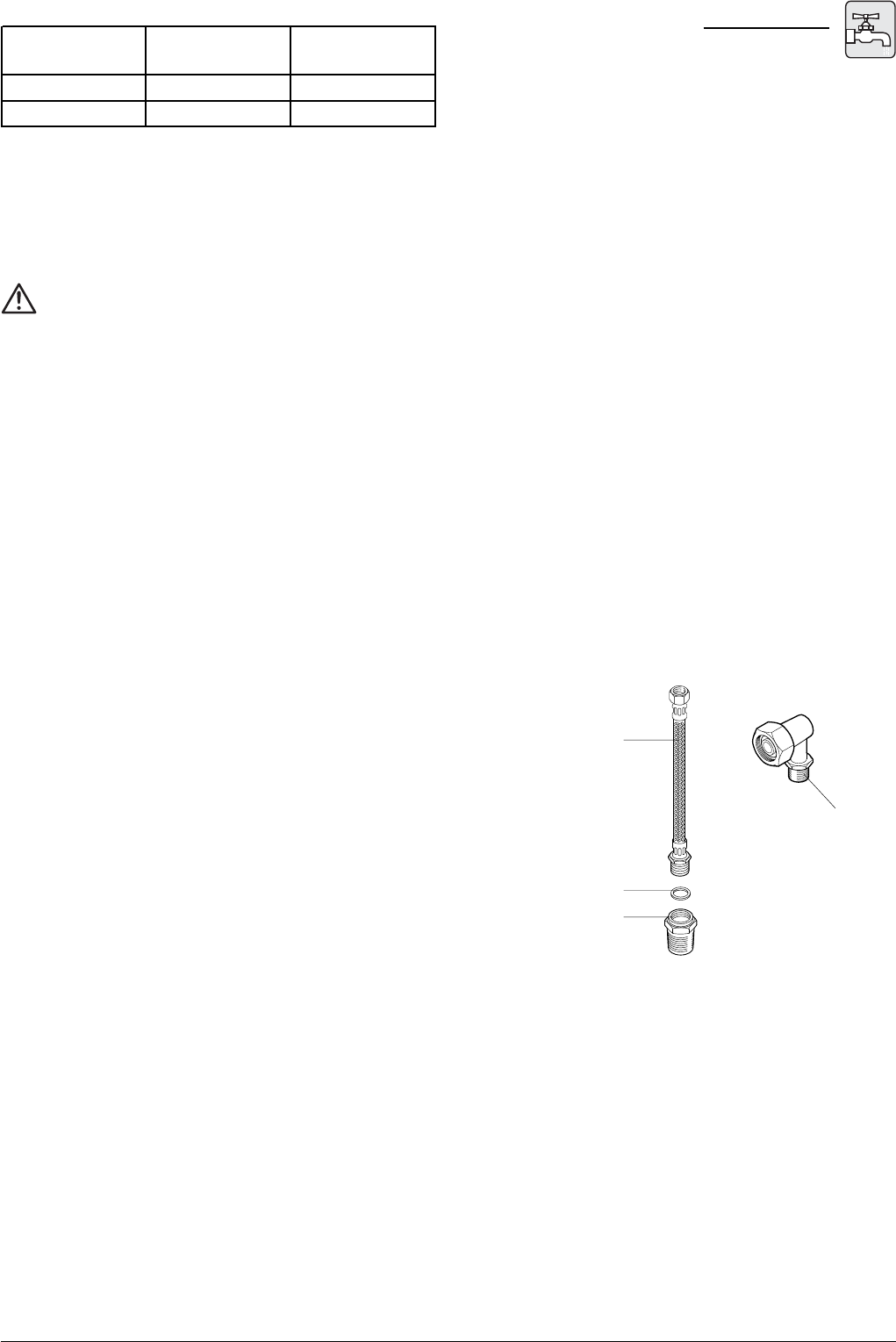

Fig. 3 - Water connections

HOT OUTLET LINE

(CONNECTED TO HEAT

EXCHANGER)

3/8” WASHER

3/8” x 1/2”

BRASS FITTING

COLD WATER

INLET

WATER CONNECTIONS

Install the heater centrally in the building if possible and

make hot water piping runs as short as possible When facing

the heater, the cold water inlet will be on the right and the

hot water outlet on the left.

Although water piping throughout the building may be other

than copper, copper or galvanized piping should be used

when connecting to the heaters ½” male NPT connectors

(follow local codes if more stringent). Plastics or other PEX

type plumbing line materials are not suitable for connecting

directly to the water heater. Keep water inlet pipe to no less

than ½” (19.05mm) diameter to allow the full flow capacity.

If the cold and hot connections to the heater are reversed,

the heater will not function.

The 38B is provided with one rigid elbow connector that

must be connected to the cold inlet fitting of the brass water

valve, no pipe dope or thread tape is to be used at this joint.

The outlet flexible connector is supplied attached to the

heat exchanger, the supplied 3/8” washer and 3/8”x1/2”

brass fitting should be attached to it to allow a ½” NPT

connection to be made. See Fig. 3.

Be certain there are no loose particles or dirt in the piping.

Blow out or flush the lines before connecting to the water

heater. Full port valves should be installed on both the cold

water supply and hot water outlet lines to facilitate servicing

the heater. For installation on a private well system with the

use of a pressure tank, the lowest pressure range setting

recommended is 30-50 psi (2.07-3.45 bar).

Altitude Natural Gas Liquid Propan

e

inches W.C: inches W.C:

0' - 2.000 ft 5.7" 10.5"

2.000 ft - 4.500 ft 4.6" 8.4"