P.O. BOX 1467 • MADISON, WI 53701-1467

Call toll-free 1-800/334-6011 • Fax 608/257-4357

10006007 11.05

B2203179C

©2005 Research Products Corporation

Printed in USA

1ST

STG

COMP.

REV

VALVE

HEAT

DEFROST

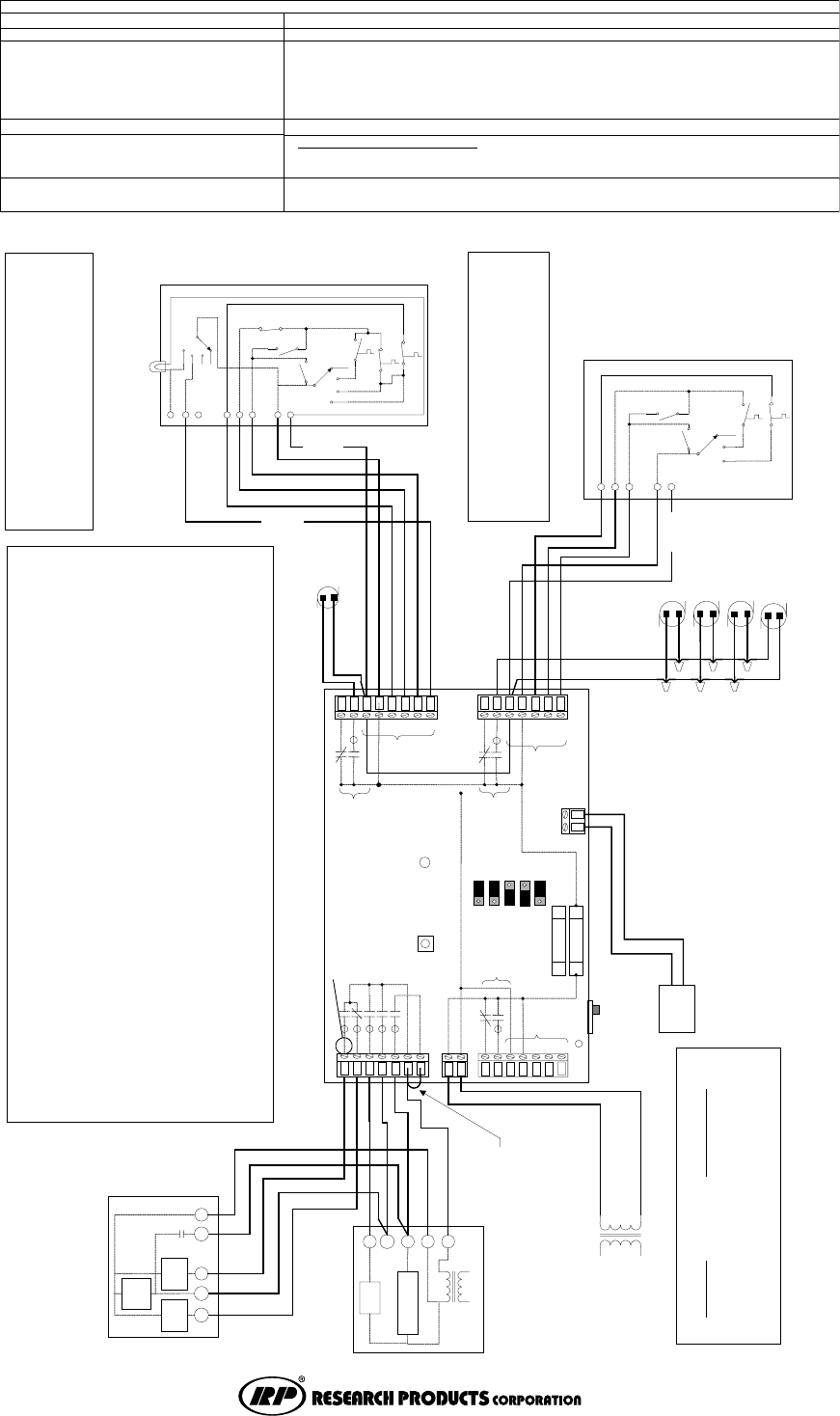

OUTDOOR UNIT

LOW VOLTAGE CONTROL ONLY

REV

VALVE

COOL

CWBYO

AUX.HEAT/

EMERG. HEAT

FAN

RELAY

R

C

W2

Y

G

COMP.

L1

L2

120

VAC

24

VAC

120

VAC

24

VAC

TRANSFORMER

Aprilaire

®

MODEL 6303

CONTROL PANEL

SHOWN WITH TYPICAL SINGLE STAGE HEAT PUMP AND ONE STAGE OF SUPPLEMENT HEAT

R

G

Y

W

X

FAN AUTO

FAN ON

HEAT

COOL

OFF

1ST STAGE HEAT

1ST

STAGE

COOL

AIR HANDLER

LOW VOLTAGE

CONTROL ONLY

24V (HOT)

24V (COMMON)

REV. VALVE - COOL

AUXILIARY HEAT

COMPRESSOR

FAN

REQUIRED

24V (HOT)

24V (COMMON)

HEAT

COOL

ZONE 1 THERMOSTAT

HEAT PUMP THERMOSTAT

(If Heat/Cool thermostat, wire same as Zone 2)

ZONE 2 THERMOSTAT

MUST NOT BE HEAT PUMP THERMOSTAT

USE SEPARATE 24VAC TRANSFORMER - DO

NOT USE HVAC SYSTEM TRANSFORMER

RECOMMENDED HEAT PUMP THERMOSTATS

(ZONE 1 ONLY)

Aprilaire® 8346: non-programmable

Aprilaire® 8365: 5/2 day programmable

Aprilaire® 8570: 7 day programmable

RECOMMENDED HEAT/COOL THERMOSTATS

(ZONES 1-3)

Aprilaire® 8344: non-programmable

Aprilaire® 8363: 5/2 day programmable

Aprilaire® 8570: 7 day programmable

FIELD INSTALLED JUMPER

REQUIRED FOR SINGLE

TRANSFORMER SYSTEMS

6303 WIRING DIAGRAM

ZONE 1

DAMPER

OPTIONAL

8052

Sensor

CONTROL PANEL SET UP

1. Set Z1 HC/Z1 HP pin jumper block to the left two pins (Z1 HC) if installing a heat/cool thermostat in Zone 1.

Set the pin jumper block to the right two pins (Z1 HP) if installing a heat pump thermostat in Zone 1 for

thermostat control of Emergency Heat.

2. Set GAS/ELECTRIC pin jumper block to the right two pins (ELECTRIC) for most installations. This will

energize the Fan (G equipment terminal) with an Auxiliary or Emergency Heat Call (W). Set the pin jumper block

to the left two pins (GAS) if the auxiliary heat source is gas (or propane or oil).

3. Set the PURGE/NO PURGE pin jumper block to the left two pins (PURGE) if it is desired to have the zone

control panel control a 60 second purge cycle at the end of a cool call or electric heat call. Set the pin jumper

block to the right two pins (NO PURGE) if equipment control of the purge cycle is desired.

4. Set the HT-160/120 pin jumper block to the left two pins (Ht-160) to cut out the heating equipment at 160°F to

prevent overheating. Set the HT-160/120 pin jumper block to the right two pins (Ht-120) to cut out the heating

equipment at 120°F.

5. Set the CL-45/40 pin jumper block to the left two pins (CL-45) to cut out cooling equipment at 45°F to prevent

freezing the indoor cooling coil. Set the pin jumper block to the right two pins (CL-40) to cut out cooling

equipment at 40°F.

6. Ensure that the E-HEAT switch, in the lower left hand corner of the control panel, is in the off position.

7. Follow the Sequence of Operation to checkout the system after installation. Push and hold the TDO button to

speed up the internal clock and avoid built in time delays.

O

R

G

Y

W2

B

X

L

FAN AUTO

HEAT or COOL

FAN

ON

EHEAT

HEAT

COOL

OFF

1ST

STAGE

EHEAT

HEAT

COOL

OFF

OPTIONAL

Normal Flashing LED not flashing

No Heat call or Cool call

- TSTATS not operating properly. If Zone 1 is set up as a heat pump thermostat, it requires an O + Yfor cool call

and Y for a heat call.

- 4 minute minimum off time delay in effect - push TDO

- Missing jumper between equipment RH&RC - required for single transformer systems

- Equipment interrupt due to high/low temperature limit

- Heat/Cool Changeover limit in effect and an opposing call is being answered in another zone

No power to control panel - check power wiring

Won't stop calling

Minimum on time delay in effect (2 minutes for heat, 4 minutes for cool)

SYMPTOM

CAUSE

TROUBLESHOOTING

Heat calls being satisfied with Emergency Heat

- Heat Pump TSTAT installed in Zone 1: If Zone 1 is in Emergency Heat mode, all heat calls from other zones will be

satisfied with Emergency Heat until Zone 1 makes a compressor call (normal heat or cool call).

- Onboard E-HEAT switch is in the ON position and all calls for heat answered with Emergency Heat

No Emergency Heat Call

- Zone 1 W terminal not energized or energized with Y terminal

- Onboard E-HEAT switch in the OFF position (Heat/Cool TSTATS installed in all zones)

FUSE - 3A

NO

NC

C

R

W

Y

G

NO

NC

C

R

W

Y

G

O

24V

W2

RC

RH

EQUIPMENT OUTPUTS

B

O

G

Y

B TERMINAL IS NOT A 24V

COMMON CONNECTION.

AC

SPARE FUSE

NORMAL

FLASHING

T.D.O.

(TIME DELAY

OVERRIDE)

C

R

W

Y

G

NO

NC

ZONE 3

TSTAT

INPUT

S

ZONE 1

ZONE 2

ZONE 3

ELECTRIC

PURGE

HT-160

CL-45

GAS

NO

PURGE

120

40

Z1 HC

Z1 HP

PLENUM

SENSOR

E-HEAT

ON

OFF

ZONE 2

DAMPER

INPUTS

ZONE 2

TSTAT

INPUTS

ZONE 1

TSTAT

INPUTS

ZONE 1

DAMPER

INPUTS

Sensor must be installed

prior to powering up the

control panel

FAN

ZONE 3

DAMPER

INPUT

S

DAMPER WIRING NOTE

THE MAXIMUM AMOUNT OF CURRENT THAT

CAN BE SWITCHED THROUGH THE ZONE

PANEL IS 3 AMPS. IF MORE THAN 6

DAMPERS COULD BE POWERED AT ONE

TIME, INSTALL DEDICATED DAMPER

TRANSFORMERS AND A MODEL 8028

DAMPER POWER DISTRIBUTION PANEL.

WIRE ACCORDING TO THE INSTRUCTIONS

PROVIDED WITH THE MODEL 8028.

MAX # OF POWERED REQUIRED

DAMPERS TRANSFORMER

3 OR LESS 40 VA

4 THRU 6 75 VA

7 OR MORE 40 VA per 3 DAMPERS

(SEE DAMPER WIRING NOTE IF 7 OR MORE)