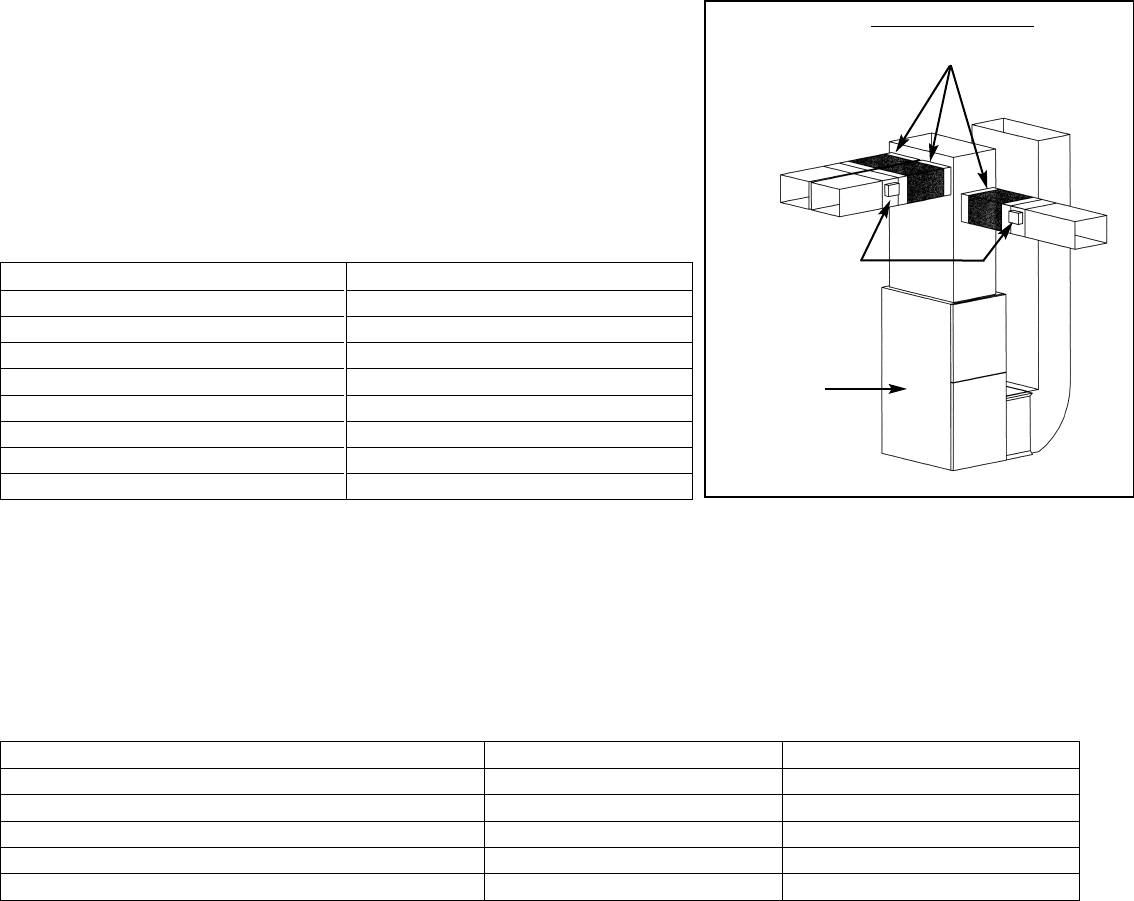

2. MOUNT THE 8052 PLENUM TEMPERATURE SENSOR (provided)

IMPORTANT: Do not mount the sensor in direct line-of-sight of the heat exchanger,

cooling coils, or UV lights as they may cause the sensor to report false temperature

readings.

• Locate the sensor in the supply trunk, after the heat exchanger and cooling coils and

before the zone dampers (shaded areas). (See Figure 2)

• Mount the 8052 Sensor according to Installation Instructions provided with the sensor.

• Wire the 8052 Sensor to the Plenum Sensor terminals on the zoned comfort control panel

before power is applied to control panel.

• Measure the resistance across the Plenum Sensor terminals (before power is applied to

the panel) and confirm that it roughly corresponds to the ambient temperature values

listed in the table below.

• NOTE: In order for the control panel to recognize a sensor, it must be wired to the panel before power is applied.

3. PROVIDE CONTROL SYSTEM POWER

Install a transformer, separate from the transformer provided for the HVAC equipment, to provide power for the control panel, thermostats and

dampers. The size of the transformer depends on the greatest number of dampers that will be energized at any given time. If more than 6

dampers could be powered at one time, install dedicated damper transformers and a Model 8028 Damper Power Distribution Panel. Use the table

below to size the added transformer(s). Aprilaire Flexible Link Dampers require 12 VA per damper. Multiply the number of dampers by 12 and

select a transformer that meets or exceeds this value.

The table below illustrates.

4. SET UP THE CONTROL PANEL FOR THE APPLICATION

• Z1 HC/Z1 HP is set according to the type of thermostat installed in Zone 1. If a heat/cool thermostat is used in Zone 1, place the pin jumper

block on the left two pins (Z1 HC). While set as Z1 HC, emergency heat can only be controlled with the on board E-HEAT switch. If a heat pump

thermostat is used in Zone 1, place the pin jumper block on the right two pins (Z1 HP). Using a heat pump thermostat in Zone 1 allows for

emergency heat control from the Zone 1 thermostat.

• GAS/ELECTRIC refers to the auxiliary heat source. If gas (or propane or oil) heat is to be used, place the pin jumper block on the left two pins

(GAS). This will allow the auxiliary heating equipment to control the fan operation through the use of a plenum switch. If electric heat is to be

used, place the pin jumper block on the right two pins (ELECTRIC).

• PURGE/NO PURGE determines whether the zone control panel or the equipment will control the fan purge. If set to PURGE, pin jumper block on

left two pins, the G terminal and any energized damper terminals will remain energized for a one-minute purge delay following the completion

of a cool call, regular heat call or an electric auxiliary heat call. If set to NO PURGE, pin jumper block on right two pins, the G terminal will de-

energize immediately and any energized damper will remain energized for 3.5 minutes following the completion of a call. The NO PURGE

setting is designed for use with systems where the equipment has a built-in fan purge.

• HT-160/120: If using a plenum temperature sensor, this jumper controls the temperature at which the heating equipment will cut out to prevent

overheating. Set the high limit temperature that is appropriate for the equipment being used. For a high limit temperature of 160°F, place the pin

jumper block on the left two pins (HT-160). For a high limit temperature of 120°F, place the pin jumper block to the right two pins (120).

• CL-45/40: If using a plenum temperature sensor, this jumper controls the temperature at which the cooling equipment will cut out to prevent

freezing the indoor coil. For a low limit temperature of 45°F, place the pin jumper block on the left two pins (CL-45). For a low limit temperature

of 40°F, place the pin jumper block to the right two pins (40).

5.WIRE THE SYSTEM

Use standard 18 or 20 gauge thermostat wire, color coded wherever possible to simplify troubleshooting. The wiring diagram and the

THERMOSTAT SELECTION guide below are to be used to guide you through wiring the system.

Highest Number of Powered Dampers

3 or Less

4

5

6

7 or More

VA Required

36 VA or less

48 VA

60 VA

72 VA

No. of Dampers* 12

Select Transformer

40 VA

50 VA

75 VA

75 VA

75 VA + 40 VA / 3 Dampers

Ambient Temperature (°F)

30

40

50

60

70

80

90

100

Resistance (kΩ)

7.8

7.2

6.6

6.0

5.4

4.8

4.2

3.6

ZONED COMFORT CONTROL:

MOUNT PLENUM SENSOR IN

SHADED AREA

ZONE DAMPERS

UPFLOW

FURNACE

FIGURE 2

90-690