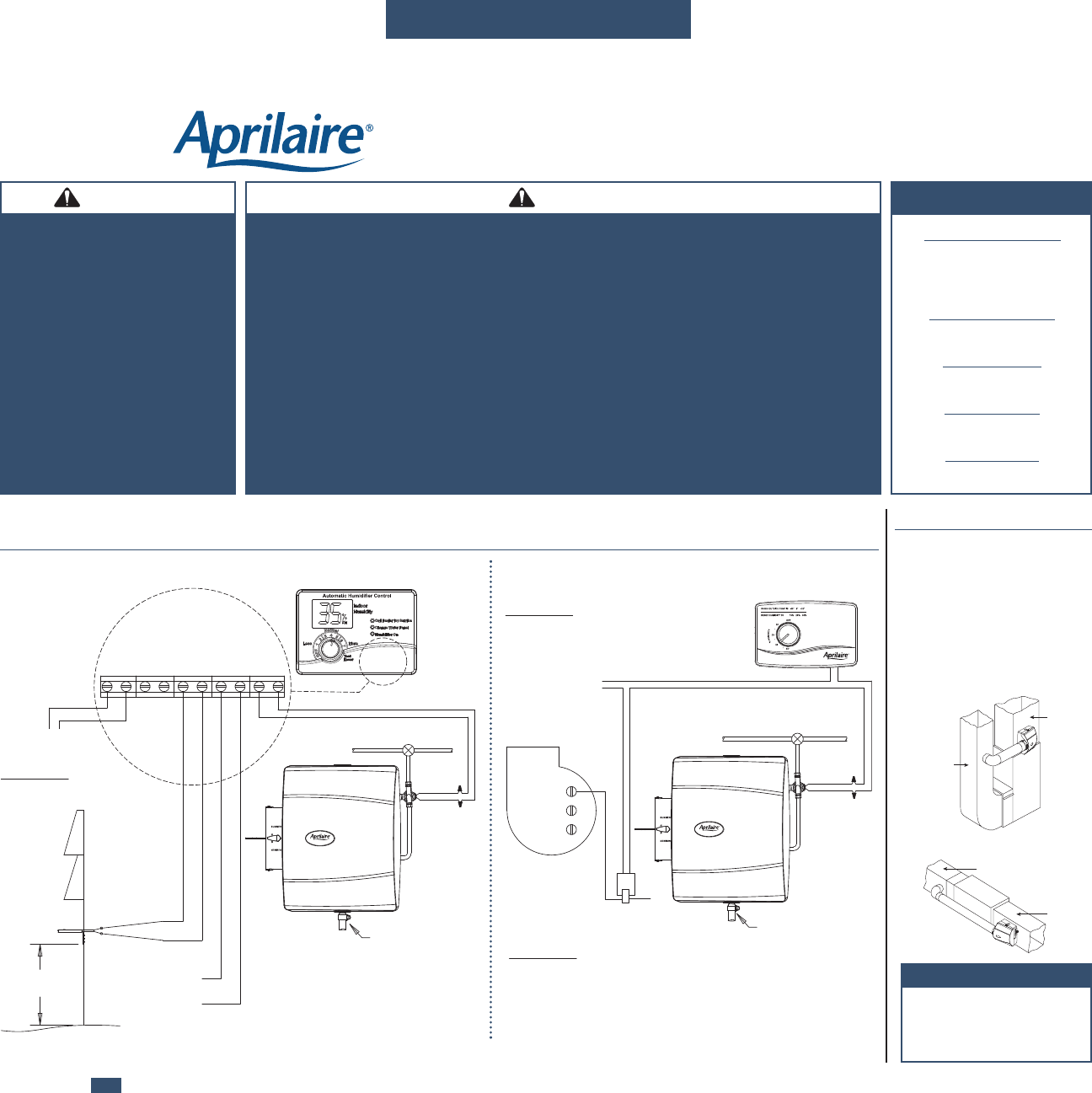

FURNACE

BLOWER MOTOR

MODEL 50

CURRENT

SENSING RELAY

(IF REQUIRED)

24 VAC FURNACE

ACCESSORY TERMINALS

OR TRANSFORMER

(10VA MINIMUM)

SHUT-OFF

(SADDLE VALVE)

WATER SUPPLY

YELLOW

24V SOLENOID

VALVE WIRES

IMPORTANT

USE 120 VAC POWER SOURCE OTHER THAN FURNACE MOTOR

CIRCUIT. HOWEVER, THE TRANSFORMER CAN BE POWERED

OFF THE HOT 120 VAC LINE BEFORE IT ENTERS THE FURNACE.

• DO NOT WIRE TRANSFORMER INTO FURNACE BLOWER CIRCUIT.

IMPORTANT

WHEN MODEL 50 CURRENT SENSING RELAY IS USED:

• WIRE MODEL 50 CURRENT SENSING RELAY INTO

24 VAC HUMIDIFIER CONTROL CIRCUIT ONLY!

DO NOT INSTALL IN TRANSFORMER PRIMARY CIRCUIT.

CONNECT DRAIN LINE HERE

COMMON

HI

LO

WATER SUPPLY

COMMON

24 VAC FURNACE

ACCESSORY TERMINAL

CONTINUOUSLY POWERED

24 VAC TRANSFORMER

PROVIDED WITH HUMIDIFIER

SHUT-OFF

(SADDLE VALVE)

YELLOW

24V SOLENOID

VALVE WIRES

IMPORTANT

DO NOT WIRE TRANSFORMER

INTO FURNACE BLOWER CIRCUIT.

NORTH, EAST

OR WEST SIDE

OF HOME

RCAB ODT CfW/G H

CONNECT DRAIN LINE HERE

ABOVE EXPECTED

SNOW LINE

NOTE: IF 120V, INSTALL 24V TRANSFORMER.

TERMINALS MAY BE LABELED: “HUM”, “ACC” OR “EAC”

CONSULT FURNACE MANUFACTURER FOR VOLTAGE AND

OPERATION PARAMETERS OF ACCESSORY TERMINALS.

NOTE: SEE CONTROL INSTRUCTIONS FOR OTHER

WIRING OPTIONS.

OUTDOOR

TEMPERATURE

SENSOR OR

MANUAL MODE

RESISTOR

READ COMPLETE SAFETY INSTRUCTIONS AND INSTALLATION TEMPLATE BEFORE STARTING INSTALLATION

This product must be installed by a qualified heating and air conditioning contractor. Failure to do so could result in serious injury from electrical shock.

This product must be installed in compliance with all local, state and federal codes.

Proper humidification and humidity control also requires that the home be constructed in accordance with local codes and good building practices.

ATTENTION INSTALLER:

MODEL 500 SERIES HUMIDIFIER

TheModel500and500M Aprilairecanbe

installedoneitherthesupplyorreturn

plenumofa forced airhandlingsystem and

iseasilyreversiblefor installationwith

right handor lefthand bypass duct

connections. The humidifier dimensions

andserviceability mustbe considered

when selectingthe bestlocationforthe

humidifier.Here are2 examples ofmany

types of installations.

RESEARCH PRODUCTS CORPORATION • P.O. BOX 1467 • MADISON, WI 53701-1467 • CALL 800/334-6011 • FAX 608/257-4357

RETURN

SUPPLY

S

RETURN

R

SUPPLY

S

Horizontal

Upflow

90-120790-1204

90-1079

WARNING

1. ELECTRICAL SHOCK HAZARD.

Disconnect electrical power to the

furnace before starting installation.

Failure to do so could result in

serious injury from electrical shock.

2.

SHARP EDGES HAZARD. Sharp

edges may cause serious injury from

cuts. Use care when making plenum

openings and handling ductwork.

3.

RISK OF SCALDING. Water

temperature over 125°F can cause

severe burns and scald instantly.

Shut off the hot water supply before

disconnecting or tapping into any

hot water supply line.

SPECIFICATIONS

H

UMIDIFIER DIMENSIONS

Width (including solenoidvalve): 15

5

⁄8”

Height

(includingdrainspud): 13”

Depth

: 10

1

⁄4”

BYPASS DUCT OPENING

6” diameter

PLENUM OPENING

9

1

⁄2”W x 9

1

⁄2”H

WATER FEED RATE

3 gph

ELECTRICAL DATA

24 VAC-60 Hz, 0.5 AMP

CAUTION

1. Do not install humidifier where freezing temperatures

could occur. The water line could freeze and crack

causing water damage to the home.

2. Do not install humidifier or bypass connection on the

furnace jacket.

3. Do not install humidifier or bypass connection on a

plenum face where the blanked off ends of the cooling

coil will restrict air movement through the humidifier.

4. Do not set humidity level above recommended or to

recommended level if condensation exists on inside

windows of any unheated space, as condensation

damage may result. Excess humidity can cause

moisture accumulation which can allow the possibility

for mold growth in the home.

5. Do not connect Model 500 or 500M transformer

to blower motor wiring. Premature component

failure may result.

6. When installing Humidifier Control on downflow

furnace, ensure blower continues to run after a

heatcall issatisfiedtoeliminate high temperatures

from damaging the Humidifier Control.

7. Do not install humidifier where water pressure

exceeds 125 psi, since damage to the humidifier

may result. Follow codes in effect concerning

pressure reduction.

8. Do not install humidifier on systems with

greater than 0.4 in. wg pressure differential

between supply and return plenums.

RISK OF PROPERTY AND EQUIPMENT DAMAGE.

INSTALLATION OPTIONSRECOMMENDED WIRING DIAGRAMS

(SEE STEP 7 ON BACK AND “HUMIDIFIER CONTROL SAFETY AND INSTALLATION INSTRUCTIONS” FOR DETAILED WIRING INSTRUCTIONS)

Model 500M

MANUAL CONTROL

Model 500

DIGITAL HUMIDIFIER

CONTROL

NOTE

When installing Aprilairehumidifier

ona heat pump system,use hot

water. The heated watersupplements

thereducedsupplyairtemperature

asaddedheatfor evaporation.