4949

4949

49

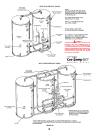

4. Adjust pilot flame.

To adjust the pilot flame, remove the cap screw from the

pilot adjusting valve and turn to deliver a sufficient flame

at the pilot burner to cover 3/8" to 1/2" (10-12mm) of the

sensing probe tip. See fig. 42.

FIGURE 42

If the pilot burner ignites but the main burner fails to light, check for

gas flow to the main burner.

Check for good terminal connection at the sensing probe at the

pilot burner assembly.

Check for electrical power to the valve. If electrical power and gas

are present at the valve and the valve does not open when system

calls for heat, replace valve.

3. PILOT BURNER - NON-I.I.D. MODELS

Servicing of the pilot burner (every six months) includes keeping

pilot shield free of lint, cleaning the burner head, the primary air

opening and the orifice pilot burner, fig. 43a.

To ensure maximum millivolt output, the pilot burner flame should

envelop 3/8 to 1/2 inch of the thermocouple tip in fig. 43a. The

electrical output of the thermocouple will be affected by:

PIEZO PILOT IGNITOR

FIGURE 43A

1. Low gas pressure

• Adjust pilot flame by means of the pilot gas adjustment

located in the gas valve.

• The pilot flame should envelop 3/8 to 1/2 inch of the tip of the

thermocouple. Remove pilot adjustment cover screw,

fig. 43b. Turn inner adjustment screw or pilot adjusting valve

clockwise to decrease, or counterclockwise to increase pilot

flame. Be sure to replace cover screw on combination gas

valve after adjustment to prevent possible gas leakage.

FIGURE 43B

2. Clogged pilot burner orifice.

• Clean or replace orifice. A clogged orifice will restrict gas

flow and result in low thermocouple output.

3. Incorrect orifice.

• Replace. Orifice size is stamped on the wrench flats.

4. Clogged primary air opening.

• Restricted air passages will soften the pilot flame and result

in poor thermocouple flame impingement.

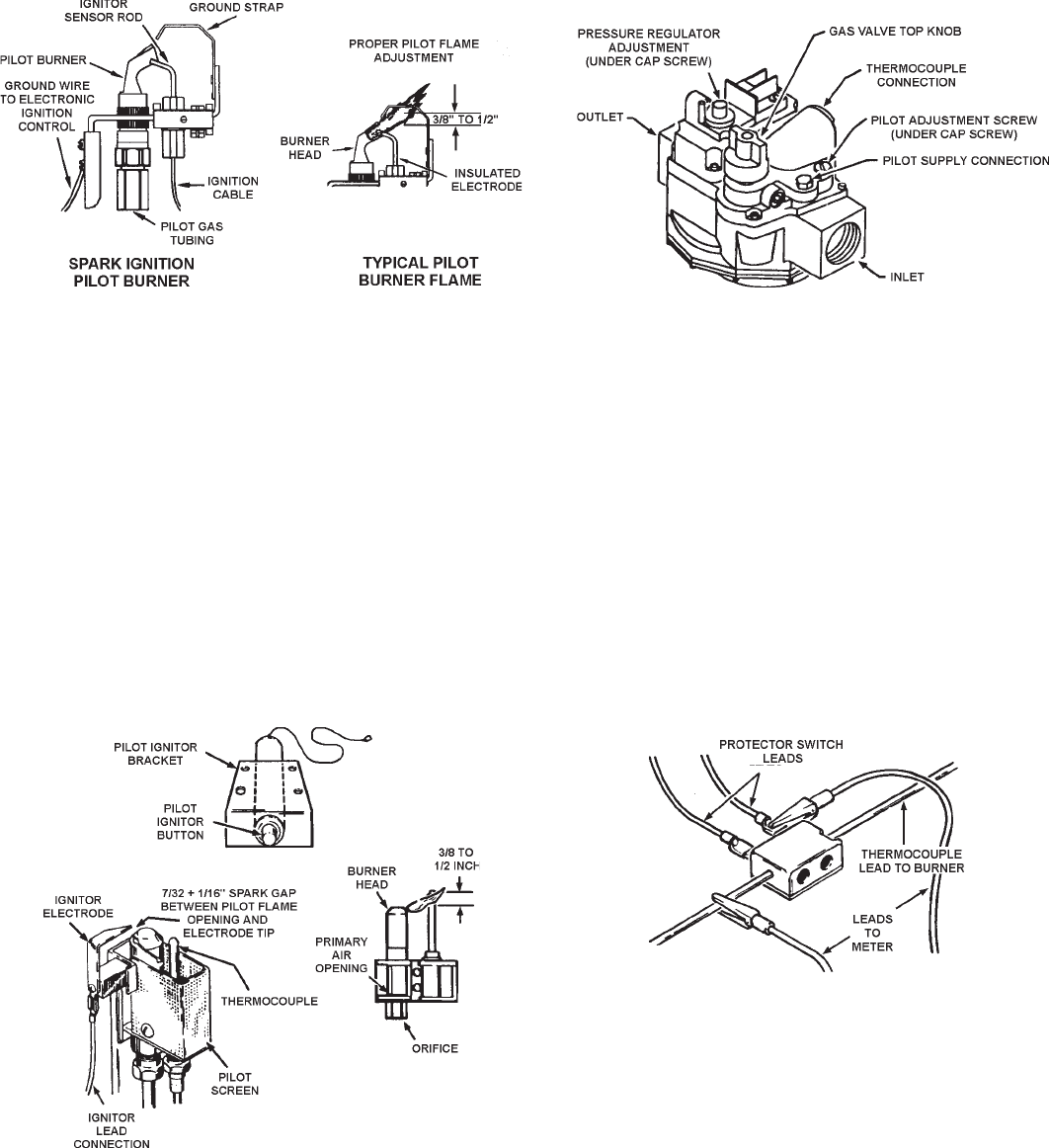

CLOSED CIRCUIT TEST

1. Attach the leads from a millivolt meter to the thermocouple and

junction block as shown in fig. 43c.

FIGURE 43C

• A satisfactory thermocouple will produce a reading of above

14 to 18 millivolts.

2. Transfer the lead on the junction block to other terminal,

figure 43d.

• A satisfactory voltage supply through the protector switch

will result in a reading of 8 to 14 millivolts.

• If a reading of less than 8 millivolts is obtained, the junction

block connections and the protector switch leads must be

checked.

(Continued from Page 46)