3232

3232

32

WATER LINE CONNECTIONS

This section provides detailed installation diagrams for typical

methods of application for the unit using a Cer-Temp 80 Recovery

System (for one temperature water), and either Booster-Recovery

or the Shure-Temp Booster-Recovery System (for two temperature

water).

These diagrams will serve to provide the installer with a reference

for the materials and methods of piping necessary for installation.

It is essential that all water and gas piping, vent connections,

electrical wiring, and check and flow regulating valves be installed

as shown on the diagrams.

Consult the installation diagrams for appropriate locations to install

the safety flow switch(es), drain valves, thermometers, relief valves

and the circulating pump(s). Apply suitable pipe thread sealing

compounds to only the male threads of parts to be connected.

If any of these parts are being replaced in a functioning system,

remember to shut off the manual gas and control valve(s) and

close off the water inlet(s). Open a nearby faucet to relieve pressure

and/or drain the boiler or system before attempting to install the

new parts.

Check the diagrams thoroughly before starting installation to avoid

errors and minimize time and materials cost.

If the system is to be filled with water for testing or other purposes

during cold weather and before actual operation, care must be

taken to prevent a downdraft entering the boiler or freezing air from

contacting the system. Failure to do so may cause the water in the

system to freeze with resulting damage to the system. Damage

due to freezing is not covered by the warranty.

This equipment must be protected against loss of water or loss of

water flow by the installation of a safety flow switch in the outlet

piping from the boiler. Piping and wiring diagrams show the

application of the accessory package for this purpose.

HARD WATER

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water boilers, water piping and other

equipment. When water softening or water treatment is not

practical, a comparatively easy method of periodic lime removal

from the boiler may be employed by installing gate valves, drain

valve and acid fill opening as shown in CLEANING AND FLUSHING

section of this manual.

TANK TEMPERATURE CONTROL

The water temperature in the storage tank is controlled by the Tank

Temperature Control. The sensing element is mounted inside

the hot water storage tank, see fig's. 31-38.

DANGER

HOT WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD BURNS

RESULTING IN SERIOUS PERSONAL INJURY AND/OR DEATH.

THE TEMPERATURE AT WHICH INJURY OCCURS VARIES WITH

THE PERSON’S AGE AND TIME OF EXPOSURE. THE SLOWER

RESPONSE TIME OF CHILDREN, AGED OR DISABLED

PERSONS INCREASES THE HAZARDS TO THEM. NEVER ALLOW

SMALL CHILDREN TO USE A HOT WATER TAP, OR TO DRAW

THEIR OWN BATH WATER. NEVER LEAVE A CHILD OR DISABLED

PERSON UNATTENDED IN A BATHTUB OR SHOWER.

The tank temperature control is adjustable from 100°F (37.7°C) to

220°F (104.4°C). It is recommended that lower water temperatures

be used to avoid the risk of scalding. It is further recommended, in

all cases, that the water temperature be set for the lowest

temperature which satisfies the user’s hot water needs. This will

also provide the most energy efficient operation of the water heater

and minimize scale formation.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA WHERE

THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO SET

TEMPERATURES. SETTING THE WATER TEMPERATURE AT

120°F (49°C) WILL REDUCE THE RISK OF SCALDS. Some states

or provinces require settings at specific lower temperatures. Below

you will find listed the approximate time-to-burn relationship for

normal adult skin. Valves for reducing point-of-use temperature by

mixing cold and hot water are available. Also available are

inexpensive devices that attach to faucets to limit hot water

temperatures. Contact a licensed plumber or the local plumbing

authority.

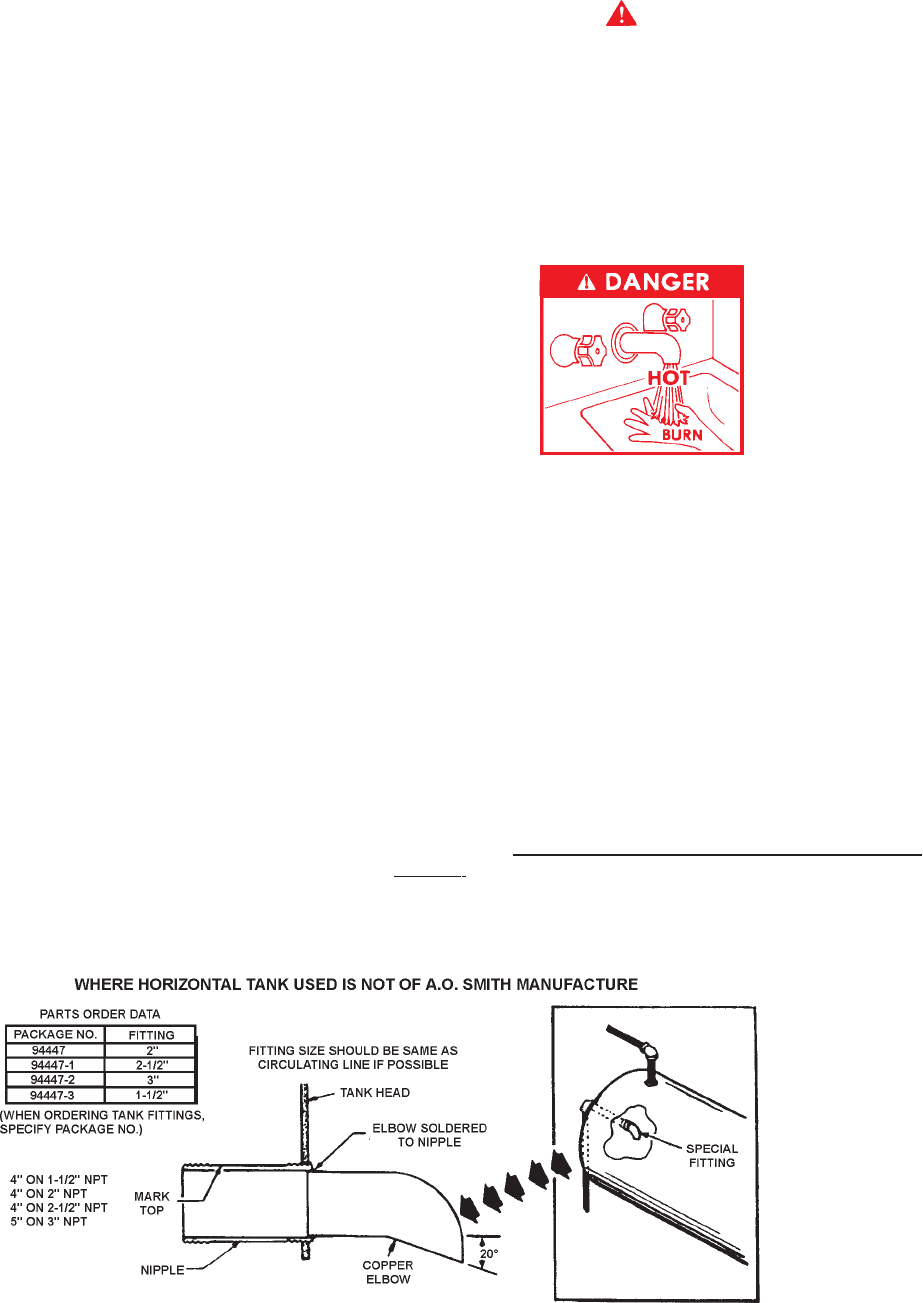

FIGURE 28

DETAIL OF TANK FITTING USED WITH MODIFIED RECOVERY

AND BOOSTER RECOVERY PIPING DIAGRAMS