4343

4343

43

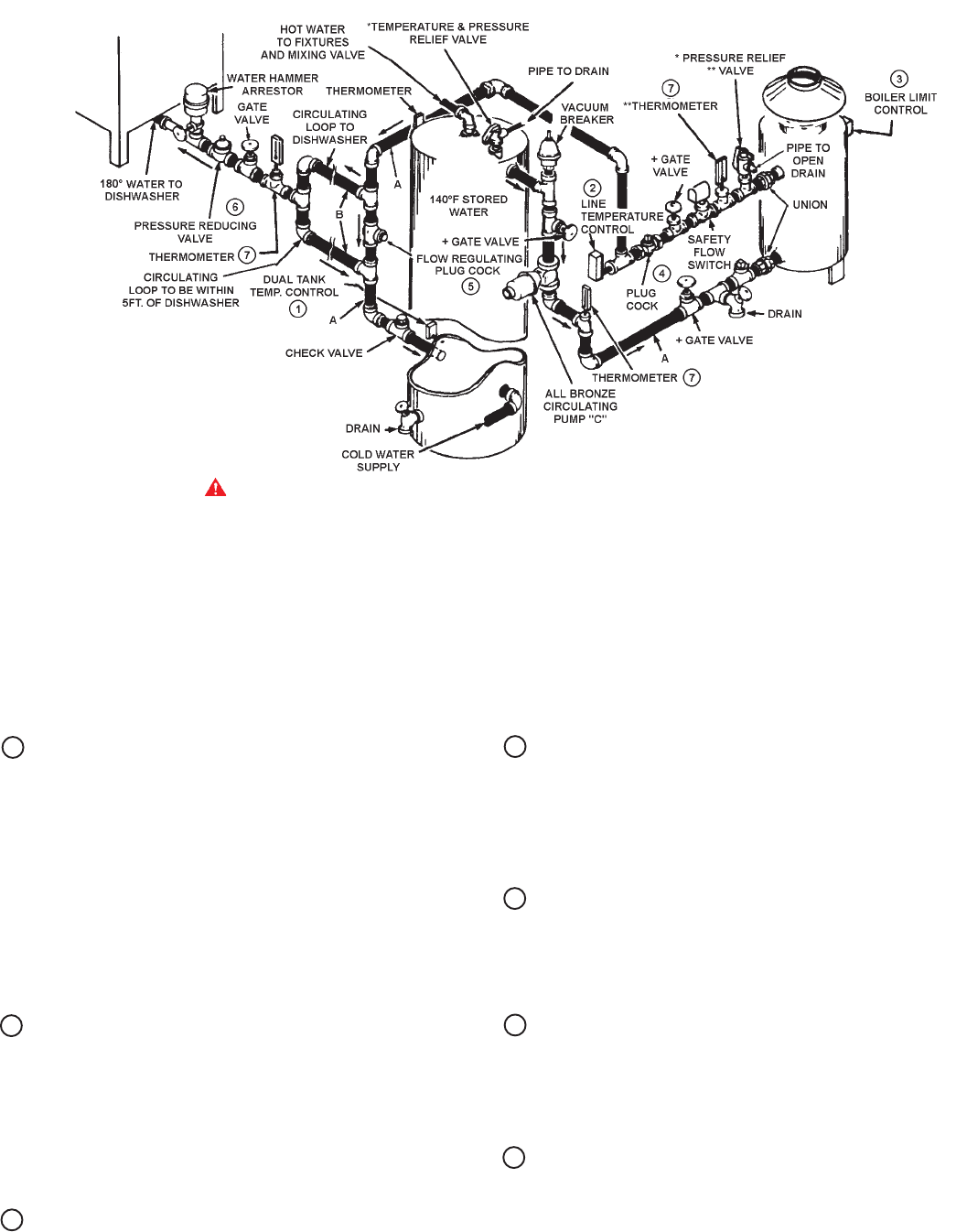

4 FLOW REGULATING PLUG COCK

(For Boiler Flow Rate Adjustment)

A slight closing of this valve may be necessary to set proper

water flow rate for 40°F temperature rise through the boiler.

Temperature rise is observed between the boiler inlet and

outlet thermometers.

5 FLOW REGULATING PLUG COCK

(For Dishwasher Recirculating Loop)

Close this valve just enough to divert sufficient flow into

circulating loop that will maintain 180°F at end of loop adjacent

to dishwasher when dishwasher is not drawing water.

6 WATER PRESSURE REDUCING VALVE

Entering water pressure to the dishwasher must be set for 20

psig flow pressure. Excessive flow pressure may waste rinse

water beyond the capacity of the boiler to maintain it at 180°F

temperature.

7 INLET/OUTLET THERMOMETERS

See A. O. Smith deliming instructions Form 4778 when normal

temperature rise between rinse thermometers starts to

increase. Thermometers should be positioned near the inlet

and outlet of the heater.

BOOSTER RECOVERY SYSTEM (PATENTED)

TWO TEMPERATURE SYSTEM WITHOUT RECIRCULATION ONE HW-300, HW-399, HW-420, HW-520,HW-610 OR HW-670

UP-FLOW MODEL COMMERCIAL BOILER WITH VERTICAL TANK

1 DUAL TANK TEMPERATURE CONTROL

The dual tank temperature control should be installed in the

lower of the two 3/4" thermostat openings in the tank.

Left Dial -High Limit

Adjust to 160°F with 20°F differential (minimum).

Right Dial -Tank Temperature

Adjust to 140°F with 8°F differential (minimum).

• May be adjusted slightly higher if total demand of

180

°

F water requires higher tank temperature.

2 LINE TEMPERATURE CONTROL

Install as close to boiler as possible. Do not insulate piping or

tee immediately adjacent to the control.

Adjust dial to 185°F with 5°F differential (minimum).

• May be set slightly higher if radiant loss from piping prevents

maintaining 180°F at dishwasher.

3 BOILER LIMIT CONTROL

(Hi Limit adjust dial 220°F with 10°F differential)

WIRING - FIGURE 24 OR 26

INSTALL IN ACCORDANCE

WITH ALL LOCAL CODES

IMPORTANT

THE INSTALLATION OF SAFETY FLOW SWITCH AS SHOWN IS REQUIRED TO

PROTECT THE BOILER IN CASE OF WATER SERVICE INTERRUPTION OR

CIRCULATOR FAILURE (A.O. SMITH PKG. NO. 211480).

+ PIPING AND FITTINGS BETWEEN GATE VALVES AND BOILERS SHOULD BE

BRASS OR BRONZE. OTHER PIPING SHOULD CONFORM TO LOCAL CODES.

GATE VALVES ARE SHOWN FOR SERVICING BOILER. HOWEVER, LOCAL CODES

SHALL GOVERN THEIR USAGE.

* PRESSURE RELIEF VALVE RATING SHOULD NOT EXCEED PRESSURE

CAPACITY OF ANY COMPONENT IN THE SYSTEM.

** INSTALL THERMOMETER AND PRESSURE RELIEF IN OPENINGS PROVIDED

ON HW-520, HW-610 & HW-670.

FIGURE 38

INSTRUCTIONS FOR NUMBERED CONTROLS SHOWN ABOVE -

DANGER

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE USE TEMPERATURE AT

FIXTURES. SEE TANK TEMPERATURE CONTROL WARNING ON PAGE 32. IF

HIGHER PREHEAT TEMPERATURES ARE NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE FOR HOT WATER SUPPLIED TO

FIXTURES.