1212

1212

12

7. Set primary system temperature control dial (thermostat) to

desired setting.

WARNING

DO NOT INCREASE GAS PRESSURE ABOVE THAT SPECIFIED

ON THE RATING PLATE, AS OVERFIRING WILL RESULT IN

DAMAGE TO THE BOILER, AS WELL AS INCREASED RISK OF

FIRE, SOOTING AND ASPHYXIATION.

If gas pressure regulator cannot be adjusted to correct pressure

with sufficient gas pressure at the valve, replace with new gas

valve.

VENTING THE BOILER - STANDARD VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING THE

BOILER MUST BE FOLLOWED TO AVOID CHOKED COMBUSTION

OR RECIRCULATION OF FLUE GASES. SUCH CONDITIONS

CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

TYPE B VENTING MAY BE USED WITH THESE BOILERS. ALL

LOCAL UTILITY REGULATIONS ON VENTING SHOULD BE

FOLLOWED.

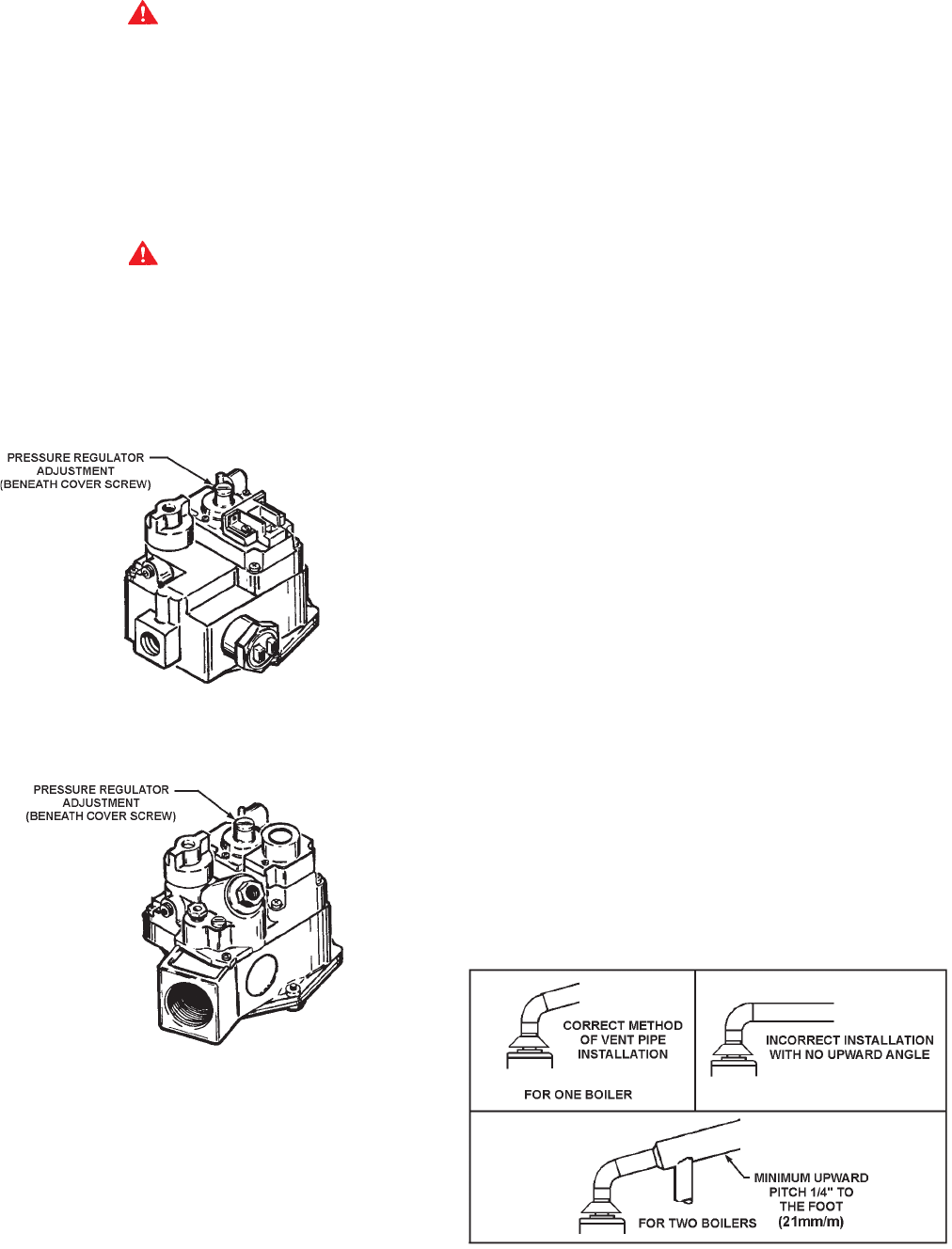

ROBERTSHAW

®

7000 DERHC

HWB/HW-300, 399,-420, -520, -610, -670 NATURAL GAS WITH I.I.D.

HW-300, -399, -420, -520, -670 LP GAS WITH I.I.D. U.S. ONLY

ROBERTSHAW

®

7000 ERHC (LP)

HWB/HW-300, 399,-420, -520, -610 SINGLE STAGE

STANDING PILOT, CANADIAN ONLY

FIGURE 6

For boilers for connection to gas vents or chimneys, vent sizing,

installation and termination shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code, ANSI Z223.1,

or Section 7, Venting Systems and Air Supply for Appliances, of the

CAN/CSA B149.1-00, Installation Codes, or applicable provisions

of the local building codes.

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

The minimum distance from adjacent public walkways, adjacent

buildings, openable windows and building openings shall not be

less than those values specified in the National Fuel Gas Code,

ANSI Z223.1 and/or CAN/CSA B149.1-00, Installation Codes;

Stack or chimney must be a minimum height of 12" (305mm)

above the annual snow fall to prevent blockage.

Building materials must not come in contact with combustion

products from stack or chimney, due to the degradating properties

of flue products.

Flue products must have a minimum clearance of 4 feet (1.22m)

horizontally from, and in no case above or below, unless a 4-foot

(1.22m) horizontal distance is maintained, from electric meters,

gas meters, regulators and relief equipment.

The Canadian B149.1-00, Installation Code specifies a 6 foot

horizontal vent terminal clearance to gas and electric meters and

relief devices (this clearance is specified as 4 feet in the U.S.

under the National Fuel Gas Code, ANSI/Z223.1). Therefore

instruction provision 134.1-b19(d), which specifies compliance

with the 4 foot clearance, as applies in the U.S. only, and the

B149.1-00 Installation Code applies in Canada.

1. DRAFT HOOD

The draft hood furnished with this boiler must be installed without

alteration. Provision must be made if the boiler is installed in

confined space or a small boiler room to accommodate draft hood

spillage and avoid risks described above. The upper air opening

called for in the AIR REQUIREMENTS section of this manual is for

this purpose.

2. VENT CONNECTION

Size and install proper size vent pipe. Do not reduce pipe size to

less than that of the draft hood outlet.

Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 4 feet or 1 meter),

noncombustible hangers and/or slip joints suitable for the weight

and design of the materials employed to prevent sagging and to

maintain a minimum upward slope of 1/4" (21mm/m) per foot

from the boiler to the vent terminals, fig. 7. Dampers or other

obstructions must not be installed in the vent. Be sure that the vent

pipe does not extend beyond the inside wall of the chimney.

VENT PIPE INSTALLATION

FIGURE 7

® Robertshaw is a registered trademark of Fulton Controls Corp.