24

VENTING SYSTEM INSPECTION

At least once a year a visual inspection should be made of the venting

system. You should look for:

1. Obstructions which could cause improper venting. The combustion

and ventilation air fl ow must not be obstructed.

2. Damage or deterioration which could cause improper venting or

leakage of combustion products.

Be sure the vent piping is properly connected to prevent escape of

dangerous fl ue gasses which could cause deadly asphyxiation.

Obstructions and deteriorated vent systems may present serious

health risk or asphyxiation.

Chemical vapor corrosion of the fl ue and vent system may occur

if air for combustion contains certain chemical vapors. Spray can

propellants, cleaning solvents, refrigerator and air conditioner

refrigerants, swimming pool chemicals, calcium and sodium chloride,

waxes, bleach and process chemicals are typical compounds which

are potentially corrosive.

If after inspection of the vent system you found sooting or deterioration,

something is wrong. Call the local gas utility to correct the problem

and clean or replace the fl ue and venting before resuming operation

of the water heater.

BURNER OPERATION AND INSPECTION

Flood damage to a water heater may not be readily visible or

immediately detectable. However, over a period of time a fl ooded water

heater will create dangerous conditions which can cause DEATH,

SERIOUS BODILY INJURY, OR PROPERTY DAMAGE. Contact a

qualifi ed installer or service agency to replace a fl ooded water heater.

Do not attempt to repair the unit! It must be replaced!

At least once a year a visual inspection should be made of the

main burner and the hot surface igniter assembly for proper fl ame

characteristics and ignition sequences. This can be done by removing

the Outer Door and viewing the main burner operation through the

Viewport on the Inner Door, see Figure 1. The main burner should

provide complete combustion of gas, ignite rapidly, give reasonably

quiet operation, and cause no excessive fl ame lifting from the burner

ports. If the proper fl ame characteristics are not evident (see Figure

20), make sure that the fl ow of combustion and ventilation air is not

blocked on the Air Intake Screen at the base of the water heater (see

Figure 21), the Lint screen on the blower assembly (see Figure 1),

and in the venting system.

You should also check for sooting. Soot is not normal and will impair

PERIODIC MAINTENANCE

proper combustion. A visual inspection of the main burner and HSI

igniter assembly should also be done at least once a year, see Figure

20.

Soot build-up indicates a problem that requires correction before

further use. Turn “OFF” gas to water heater and leave off until repairs

are made, because failure to correct the cause of the sooting can result

in a fi re causing death, serious injury, or property damage.

FIGURE 20.

BURNER CLEANING

In the event your burner or burner air openings require cleaning, turn

the blower switch to the “OFF” position and allow the burner to cool.

Call a service agency to remove and clean the burner and correct the

problem that required the burner to be cleaned.

HOUSEKEEPING

Vacuum around base of water heater for dust, dirt, and lint on a

regular basis.

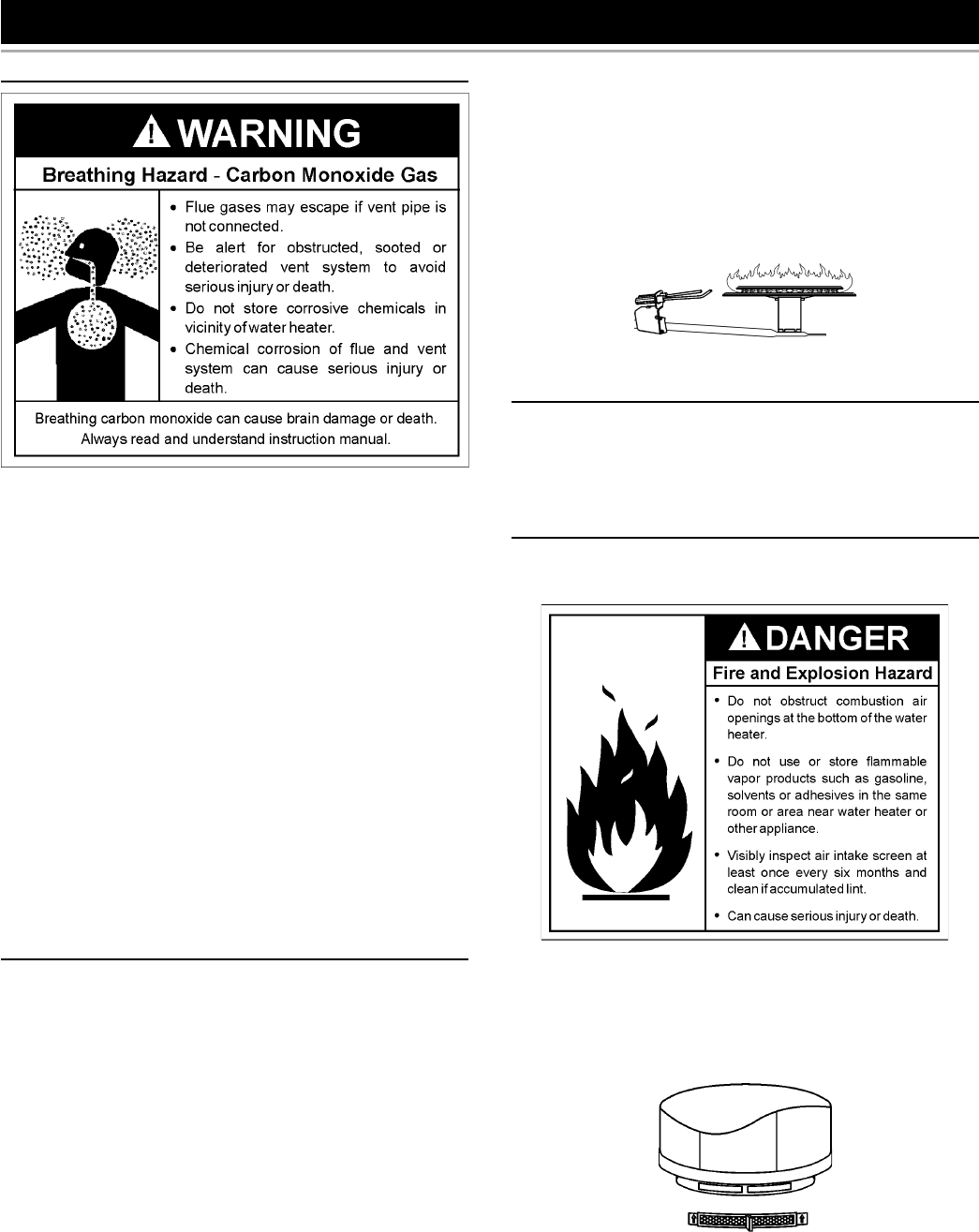

This water heater unit is supplied with a plastic Air Intake Screen that

will fi lter and prevent lint build-up on the bottom of the fl ame arrestor

of this heater. To prevent the lint build-up on the arrestor, the lint

screen must be installed on the Base Pan with the “arrows” pointing

upwards as shown in Figure 21. If the Air Intake Screen is missing

from this heater, please contact your service agency or local installer

for a replacement part.

FIGURE 21.

AT LEAST ONCE EVERY SIX MONTHS A VISUAL INSPECTION

SHOULD BE MADE OF THE AIR INTAKE SCREENS ON THE BASE

OF THE WATER HEATER AND THE BLOWER ASSEMBLY. CLEAN

IF LINT ACCUMULATIONS ARE NOTICED.