21

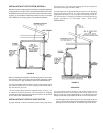

INSTALLATION OF VENT SYSTEM, SIDEWALL

With the route of the venting system and selection of materials completed,

as discussed in the section of this manual titled PLANNING THE VENT

SYSTEM, the through the wall vent terminal in place and the first section

of piping, up to first elbow, installed at the blower it is time to complete

the installation of the venting system for the sidewall installation.

FIGURE 20

Before completing the installation of the venting system be sure to read

the sections of this manual discussing the proper method of cutting

and cementing PVC pipe and fittings: VENT PIPE PREPARATION.

It is recommended that the completion of the venting system start at

the blower assembly and run to the coupling on the inside wall of

the vent terminal, Figure18.

The vent system piping should be supported every 5 feet (1.5 m)

of vertical run and every 3 feet (91 cm) of horizontal run. All piping

and fittings must be joined by the proper procedures as described

under: VENT PIPE PREPARATION.

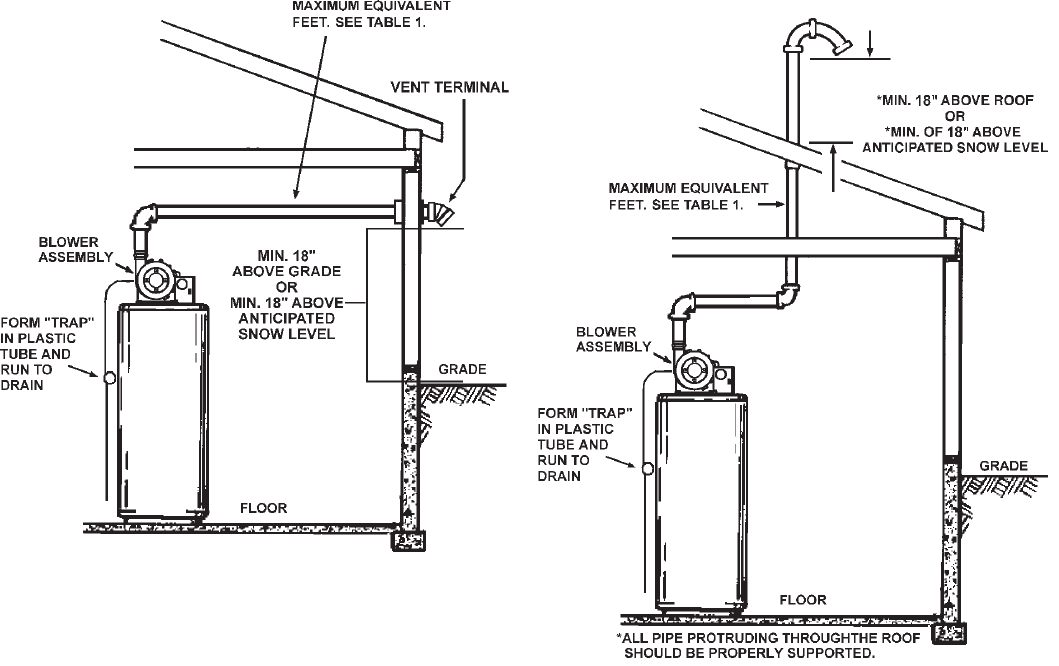

INSTALLATION OF VERTICAL VENT SYSTEM

A proper flashing or "BOOT" should be used to seal the pipe where

it exits the roof. The total vent system should not exceed the

equivalent feet of pipe as listed in Table 1.

Provide support for all pipe protruding through the roof. All piping

should be properly secured. The vent system piping should be

supported every 5 feet (1.5 m) of vertical run and every 3 feet (91

cm) of horizontal run. All piping and fittings must be joined by the

proper procedures as described under: VENT PIPE

PREPARATION.

FIGURE 21

IMPORTANT

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current edition of the

National Fuel Gas Code (ANSI Z223.1) or the Natural Gas and

Propane Installation Code (CAN/CSA-B149.1) and as listed below:

1. Vent Termination must extend a minimum of 18 inches (46 cm) above

roof or 18 inches (46 cm) above the anticipated snow level to prevent

blockage of the vent termination, as shown in Figures 20 and 21.