6

MAINTENANCE

Electric water heater maintenance consists of cleaning the tank bottom

and removing scale from the heating elements. Your dealer should be

contacted for tank and element cleaning. In some instances a hissing

sound may be heard as the scale builds up. This noise is normal although

the scale should be removed.

Periodically the temperature and pressure relief valve should be checked

to insure that it is in operating condition. Lift the lever at the top of the

valve several times until the valve seats properly and operates freely.

RELIEF VALVE

The temperature/pressure (T&P) relief valve is rated at 210°F (99°C) and

150 psi (1034kPa). This valve is a safety device to protect against

abnormally high temperature and pressures.

Never remove T&P valve from the tank and reinstall in the drain line. If

replacement of the valve is needed, it must be replaced with the

recommended valve and installed in its original location.

If the temperature/pressure relief valve discharges periodically, this may

be due to thermal expansion in a closed water supply system. Contact

the water supplier or local plumbing inspector on how to correct this

situation.

A thermal expansion tank may be needed to allow water to expand.

Expansion tanks are available from A.O. Smith Water Products Company,

5621 W. 115th Street, Alsip, IL 60803. Inspect the unit for proper operation.

Do not ignore the water discharge. Never plug the T&P relief valve.

DANGER

DANGER OF PERSONAL INJURY FROM SCALDING. WATER FROM T&P

RELIEF VALVE MAY BE EXTREMELY HOT AND IS NOT TEMPERED. USE

EXTREME CAUTION WHEN DISCHARGING VALVE. REPLACEMENT OF

T&P VALVE SHOULD BE DONE BY A TRAINED PROFESSIONAL OR A

LICENSED PLUMBING CONTRACTOR.

At least once a year, the temperature and pressure relief valve must be

checked to ensure that it is in operating condition. Lift the lever at the top

of the valve several times until the valve seats properly and operates

freely.

If water does not flow, valve may be obstructed or corroded. Remove

valve and inspect for corrosion. Have it replaced with the recommended

valve if necessary.

Removal and inspection of the valve should be done every three years.

Do not try to repair valve. Doing so will result in improper operation

which may result in a tank explosion. In areas with poor water conditions,

it may be necessary to remove and inspect the T&P valve more often

than every three years.

ANODE ROD MAINTENANCE

The anode rod is used to protect the tank from corrosion. Water tanks

are equipped with an anode rod. The submerged rod sacrifices itself to

protect the tank. Instead of corroding the tank, water ions attack and eat

away the anode rod. This does not affect the water's taste or color.

The rod must be maintained to keep the tank in operating condition.

Anode deterioration depends on water conductivity, not necessarily

water condition. It may be necessary to have the anode rod inspected

a few times during the first year to see what effect the water has had.

A corroded or pitted anode rod, in the first year, indicates high water

conductivity and should be checked and or replaced more often than an

anode rod that appears to be fairly clean. Inspection should be conducted

by a qualified technician.

REPLACEMENT PARTS

Replacement parts may be ordered through dealers, authorized servicers

or distributors. Refer to Yellow Pages for where to call or contact the

Water Products Company, 5621 West 115th Street, Alsip, IL 60803,

1-800-433-2545. When ordering parts, specify complete model no.,

serial no., (see rating plate), quantity and name of part desired. Standard

hardware items should be purchased locally.

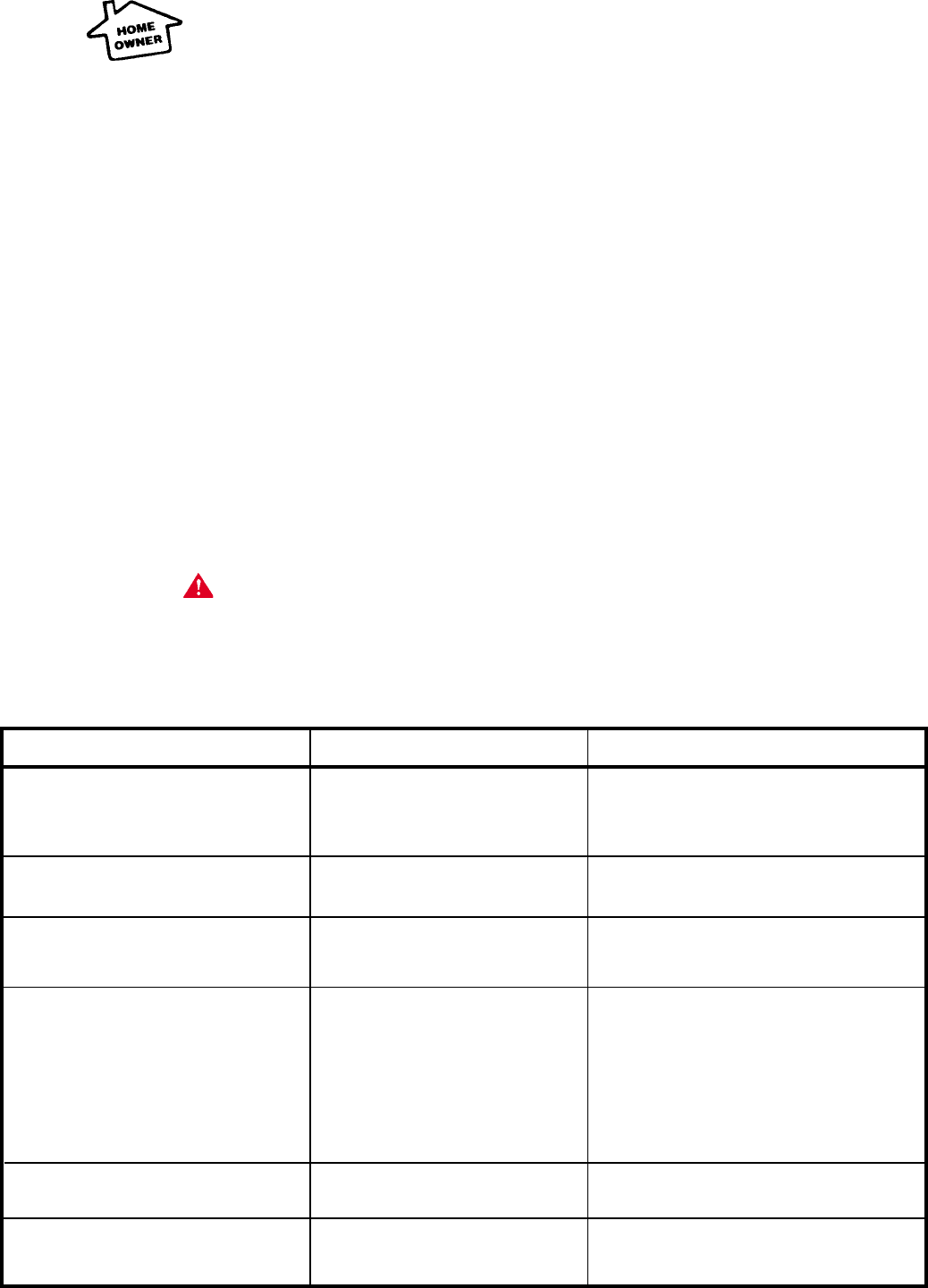

TROUBLE SHOOTING ELECTRIC WATER HEATERS

CAUSE

IMPROPERLY SEALED HOT OR COLD

SUPPLY CONNECTIONS, RELIEF VALVE

OR THERMOSTAT THREADS

LEAKAGE FROM OTHER APPLIANCES

OR WATER LINES

THERMAL EXPANSION IN CLOSED

WATER SYSTEM

IMPROPERLY SEATED VALVE

HIGH SULFATE OR MINERAL

CONTENT IN WATER SUPPLY

BACTERIA IN WATER SUPPLY

POWER SUPPLY TO HEATER IS NOT

ON

THERMOSTAT SET TOO LOW

HEATER UNDERSIZED

INCOMING WATER IS UNUSUALLY

COLD (WINTER)

LEAKING HOT WATER FROM PIPES OR

FIXTURES

HIGH TEMPERATURE LIMIT SWITCH

ACTIVATED

THERMOSTAT SET TOO HIGH

HIGH TEMPERATURE LIMIT SWITCH

ACTIVATED

SCALE ACCUMULATION ON ELEMENTS

SEDIMENT BUILD-UP ON TANK

BOTTOM

SOLUTION

TIGHTEN THREADED CONNECTIONS

INSPECT OTHER APPLIANCES NEAR WATER

HEATER

INSTALL THERMAL EXPANSION TANK (DO NOT

PLUG T & P RELIEF VALVE)

CHECK RELIEF VALVE FOR PROPER OPERATION

DRAIN AND FLUSH HEATER THOROUGHLY, AND

REFILL

CHLORINATE WATER SUPPLY

TURN DISCONNECT SWITCH ON OR CONTACT

ELECTRICIAN

REFER TO TEMPERATURE REGULATION

REDUCE HOT WATER USE

ALLOW MORE TIME FOR HEATER TO REHEAT

HAVE PLUMBER CHECK AND REPAIR LEAKS

CONTACT DEALER TO DETERMINE CAUSE: SEE

TEMPERATURE REGULATION

REFER TO TEMPERATURE REGULATION

CONTACT DEALER TO DETERMINE CAUSE: SEE

TEMPERATURE REGULATION

CONTACT DEALER TO CLEAN OR REPLACE

ELEMENTS

DRAIN & FLUSH THOROUGHLY

PROBLEM

WATER LEAKS (SEE LEAKAGE CHECKPOINTS

ON PAGE 10

LEAKING TEMPERATURE & PRESSURE RELIEF

VALVE

HOT WATER ODORS (CAUTION:

UNAUTHORIZED REMOVAL OF THE ANODE(S)

WILL VOID THE WARRANTY. FOR FURTHER

INFORMATION, CONTACT YOUR DEALER.)

NOT ENOUGH OR NO HOT WATER

WATER TOO HOT

WATER HEATER SOUNDS