8

combustible materials must be provided in accordance with

information in this manual under LOCATION OF HEATER and

INSTALLATION OF VENT SYSTEM, and with the National Fuel

Gas Code and local codes.

PLANNING THE VENT SYSTEM

Plan the route of the vent system from the discharge of the blower

to the planned location of the vent terminal.

1. Layout the total vent system to use a minimum of vent pipe

and elbows.

2. This water heater is capable of venting the flue gases the

equivalent of twenty-five (25) feet of 2 inch pipe, sixty-five (65)

feet of 3 inch pipe, or one-hundred twenty-eight (128) feet of 4

inch pipe as listed in Table 1.

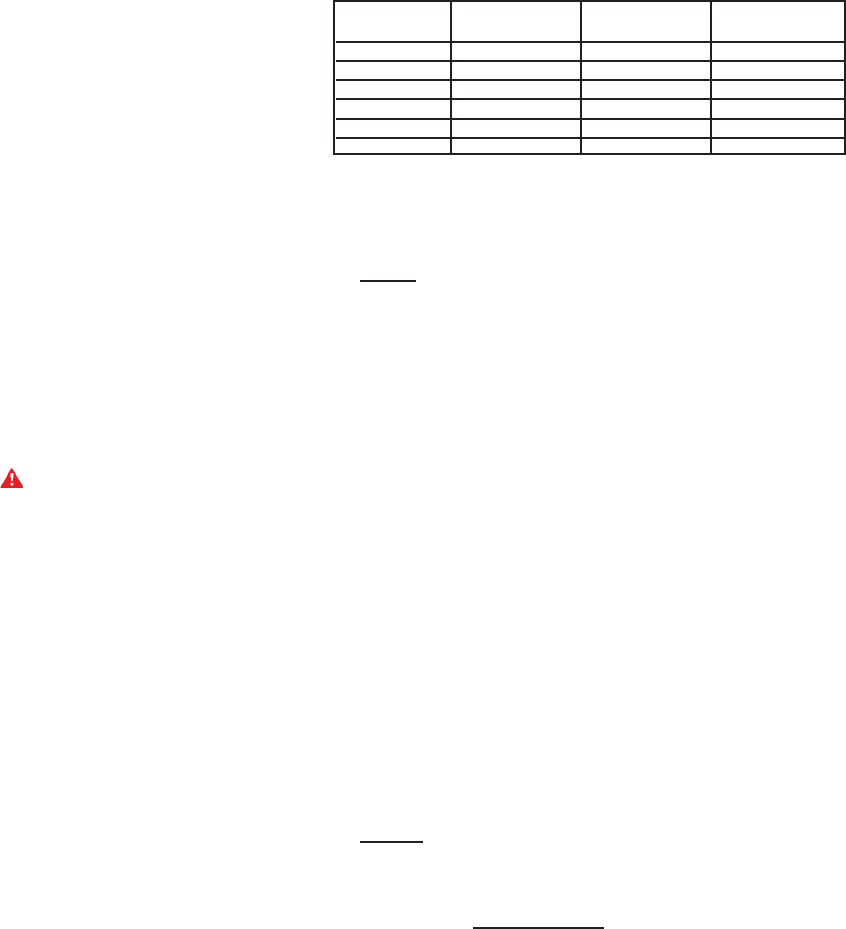

TABLE 1

Number of 2" Maximum 3" Maximum 4" Maximum

90° Elbows Pipe (Feet) Pipe (Feet) Pipe (Feet)

1 20 60 120

215 55112

3 10 50 104

4-- 4596

5-- 4088

6-- 3580

The minimum vent lengths for each of the pipe sizes is one

90° on top of the unit plus 2' of straight pipe and the appropriate

termination.

NOTE: The equivalent feet of pipe listed above are exclusive

of the termination. That is, the termination, with an installed

screen, is assumed to be in the system and the remainder of

the system must not exceed the lengths discussed above.

3. The blower discharge adapter is made to accept only straight

sections of 2" pipe. To start, a minimum of 2 inches of 2" pipe

must be attached to the blower discharge (See figure 5).

If using 2" inch vent pipe:

A minimum of 2 inches must be attached to the blower before

the first elbow. After the first elbow add the additional venting

required for the installation. The total system cannot exceed

the lengths discussed above, where each elbow is equal to 5

feet of straight pipe.

If using 3" or 4" inch vent pipe:

Two inches of pipe must be attached to the blower discharge

before adding a reducer to acquire the desired pipe diameter.

An appropriately sized 45 degree elbow (supplied locally – a

schedule 40 DWV) vent terminal must be obtained with an

equivalent screen (supplied in vent kit). The total system cannot

exceed the equivalent pipe lengths discussed above where

each elbow is equal to 5 feet of straight pipe (3" vent pipe) or

8 feet of straight pipe (4" vent pipe).

NOTE: This unit can be vented using only PVC (Class 160,

ASTM D-2241; Schedule 40, ASTM D-1785; or Cellular

Core Schedule 40 DWV, ASTM F-891), Schedule 40 CPVC/

ASTM F-441), or ABS/ASTM D-2661) pipe. The fittings,

other than the

TERMINATION should be equivalent to PVC-

DWV fittings meeting ASTM D-2665 (Use CPVC fittings,

ASTM F-438 for CPVC pipe and ABS fittings, ASTM D-

2661/3311 for ABS pipe. If CPVC or ABS pipe and fittings

are used, then the proper cement must be used for all

The drain line connected to this valve must not contain a reducing

coupling or other restriction and must terminate near a suitable

drain to prevent water damage during valve operation. The

discharge line shall be installed in a manner to allow complete

drainage of both the valve and line.

DO NOT THREAD, PLUG

OR CAP THE END OF THE DRAIN LINE.

VENT PIPE ASSEMBLY

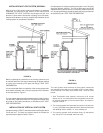

There are three parts of the vent pipe assembly that connect the

water heater exhaust (located on the lower back side of the water

heater) to the inlet of the blower assembly (mounted on top of the

water heater) as shown in Figure 1. These parts will need to be

assembled according to the instructions in the VENT PIPE

PREPARATION section of this manual. These PVC parts should

be assembled with ASTM D-2564 grade cement.

Assemble Vent Pipe Assemblies #1, #2 and #3 (See Figure 1)

prior to cementing. The preferred orientation of Vent Pipe

Assembly #1 (Condensate U-Assembly) is shown in Figure 4.

However this assembly may be rotated to a different orientation

as needed for the specific installation requirements. Note the

rotational orientation of each part by marking a line several inches

long across the joints. The long tube of Vent Pipe Assembly #2

should be approximately vertical. If it is found that either of the

two pieces of pipe in Vent Pipe Assembly #2 are too long for

proper fit-up, then remove as little material as possible to improve

the fit-up. Keep in mind that the pipes will insert slightly further

into the elbows when cement is applied as it acts as a lubricating

agent. The vertical distance from the bottom of the Condensate

U-Assembly to the floor that supports the water heater should be

approximately 0.25" (See Figure 4). Disassemble the parts and

cement back together using the alignment marks. After the cement

dries, attach the assembly to the blower and the water heater

exhaust using the supplied rubber boots and hose clamps.

A condensate trap is incorporated in the bottom of this vent pipe

assembly. See the CONDENSATE section of this manual for

further details.

VENTING

WARNING

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO

THE OUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID

RISKS OF IMPROPER OPERATION, FIRE, EXPLOSION OR

ASPHYXIATION.

VENT PIPE TERMINATION

The first step is to determine where the vent pipe will terminate.

See Figures 3, 8 and 9. The vent may terminate through a sidewall

as shown in Figure 8 or through the roof as shown in Figure 9.

IMPORTANT

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current edition of the

National Fuel Gas Code, ANSI Z223.1, 12.9.1 through 12.9.4.

Instructions on proper installation through a sidewall are provided

in Figure 3.

Plan the vent system layout so that proper clearances are

maintained from plumbing and wiring.

Vent pipes serving power vented appliances are classified by

building codes as "vent connectors". Required clearances from