6

If the unconfined space is within a building of tight construction

(building using the following construction: weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion and

ventilation must be obtained from outdoors. The installation

instructions for confined spaces must be followed.

CONFINED SPACE

When drawing combustion air from inside a conventionally

constructed building to a confined space, such a space shall be

provided with two permanent openings. ONE WITHIN 12 INCHES

OF THE ENCLOSURE TOP AND ONE WITHIN 12 INCHES OF

THE ENCLOSURE BOTTOM. Each opening shall have a free

area of one square inch per 1000 Btu/hr of the total input of all

appliances in the enclosure, but not less than 100 square inches.

If the confined space is within a building of tight construction, air for

combustion and ventilation must be obtained from outdoors. When

directly communicating with the outdoors or communicating through

vertical ducts, two permanent openings, located in the above

manner, shall be provided. Each opening shall have a free area of

not less than one square inch per 4000 Btu/hr of the total input of

all appliances in the enclosure. If horizontal ducts are used, each

opening shall have a free area of not less than one square inch per

2000 Btu/hr of the total input of all appliances in the enclosure.

WATER CONNECTIONS

Refer to figure 1 for typical installation. A suitable pipe thread

sealant must be used to prevent leakage. Please note that the

side connection plugs are not factory installed. Plugs are supplied

in a kit with the water heater.

WATER (POTABLE) HEATING AND SPACE HEATING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

2. Toxic chemicals, such as those used for boiler treatment, shall

NEVER be introduced into this system.

3. This unit may NEVER be connected to any existing heating

system or component(s) previously used with a non-potable

water heating appliance.

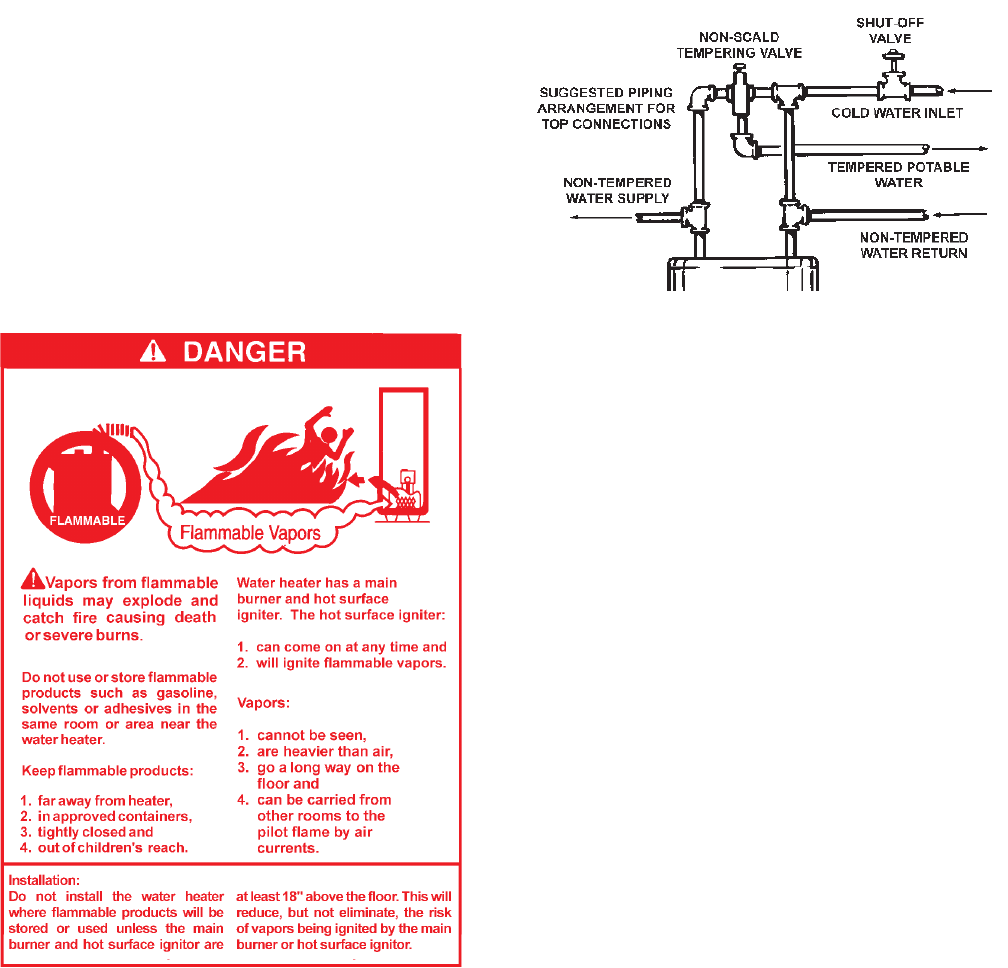

4. When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a tempering valve must be installed. Please refer

to Fig. 2 for suggested piping arrangement.

FIGURE 2

CLOSED WATER SYSTEM

A closed system will exist if a back-flow preventer (check valve),

pressure reducing valve, or other similar device is installed in the

cold water line between the water heater and the street main (or

well). Excessive pressure may develop due to the thermal

expansion of heated water causing premature tank failure or

intermittent relief valve operation. This type of failure is not covered

by the limited warranty. An expansion tank may be necessary in

the cold water supply to alleviate this situation, see Fig. 1. Contact

the local plumbing authority.

If the temperature and pressure relief valve on the appliance

discharges periodically, this may be due to thermal expansion in

a closed water supply system. Contact the water supplier or local

plumbing inspector on how to correct situation. DO NOT PLUG

THE TEMPERATURE AND PRESSURE RELIEF VALVE.

GAS CONNECTIONS

The minimum gas supply pressure for input adjustment is 5.0"

W.C. for natural gas.

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 14" WATER COLUMN SUPPLY PRESSURE. EXPOSURE

TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE DAMAGE

TO THE CONTROL WHICH COULD RESULT IN FIRE OR

EXPLOSION.

If overpressure has occurred such as through

improper testing of gas lines or emergency malfunction of the

supply system, the control must be checked for safe operation.

Make sure that the outside vents on the supply regulators and

the safety vent valves are protected against blockage. These are

parts of the gas supply system not the heater. Vent blockage may

occur during ice storms.

IT IS IMPORTANT TO GUARD AGAINST CONTROL FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

All gas piping must comply with local codes and ordinances or

with the National Fuel Gas Code (ANSI Z223.1 / NFPA-54)

whichever applies.