29

ABOVE ALL, DO NOT PLUG THE TEMPERATURE AND PRESSURE

RELIEF VALVE. THIS IS NOT A SOLUTION AND CAN CREATE A

HAZARDOUS SITUATION.

CIRCULATING PUMP

The water heating system may include a circulating pump. Where

used, it should be lubricated as directed by the circulator

manufacturer.

LOW EMISSION POWER BURNER

KEEP THE AREA AROUND THE BURNER CLEAR AND FREE OF

COMBUSTIBLE MATERIALS, GASOLINE OR OTHER FLAMMABLE

LIQUIDS OR VAPORS. DO NOT OBSTRUCT BURNER AIR

OPENINGS OR VENTILATION GRILLES FOR COMBUSTION AIR.

REMOVE LINT ACCUMULATION FROM AIR INTAKE GRILL.

The main burner flame should be visually checked once a year

for proper operation. This can be observed through the “peep

sight” port on the burner mounting plate. Burner flame should

be kept blue.

At least annually, contact a qualified service agency for burner

cleaning and other routine maintenance. For burner related

Maintenance Schedule, Troubleshooting, Flame Rod, Ignitor,

Thermal Cut-Off Switch Replacement Procedures, use burner

Operation & Maintenance Manual provided with this heater.

CLEANING FLUES

The following describes how to gain access to the tank flues for

cleaning if necessary.

1. Turn off the heater electrical disconnect switch.

2. Remove the vent connector from on top of the heater.

3. Remove the jacket top from the heater by taking out the screws

and lifting it off.

4. Remove the insulation from the top of the heater.

5. Remove the inner cover by taking out the pipe collar around

the water inlet and outlet nipple.

6. The flue baffles may now be removed by lifting out.

7. Using a wire brush, a nylon brush must not be used, remove

soot from flue passages in heater tank.

CAUTION

While cleaning tank flue passages, care must be taken that

brush does not come in contact with neither the combustion

chamber lining nor the baffle or funnel which are an integral

part of the combustion chamber, as damage could occur. The

flue passages are 48-1/2” (1,232 mm) long x 3” (76.2 mm)

diameter.

8. Upon completion of cleaning, return heater to operation by

following this procedure in reverse.

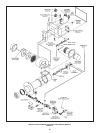

BAROMETRIC DRAFT CONTROL

- FOR BTP MODELS

The heater is equipped with a double acting barometric draft

control as shown in Figure 15. The damper gate must pivot

freely in the ring guides.

FIGURE 15

To test gate for operation, gently tap gate and observe. DO NOT

OIL.

Adjust the number of counter-weight washers on the control to

maintain a negative draft of 0.02” to 0.04” w.c. in the venting. See

VERTICAL VENTING, page 8.

NOTE THAT THIS CONTROL WILL ONLY BE PRESENT IN A

VERTICAL VENT INSTALLATION.

VENT SYSTEM

Examine the vent system every 3 months. Points of inspection

are as follows:

1. Check for obstructions and/or deterioration of vent piping and

vent hood. Replace immediately where needed.

2. Vent pipe and vent hood screen should be cleaned of foreign

material and soot. The screen is located inside the vent

hood outlet and is accessible from the outside of the hood.

Do not reach inside the vent when the heater is in operation.

3. Check all vent system connections for leakage and re-seal

as required using Hi Temp Silicone sealer or equivalent.

CHECKLIST AND SERVICE

INFORMATION

IMPORTANT

The installer may be able to observe and correct certain problems

which might arise when the unit is put into operation or when it is

re-fired after a prolonged shutdown. HOWEVER, it is

recommended that only qualified servicemen, using appropriate

test equipment, be allowed to service the heater.

BE SURE TO TURN OFF THE ELECTRICITY WHENEVER

POSSIBLE OR APPROPRIATE WHILE CHECKING EQUIPMENT.

BURNER OPERATIONAL PROBLEMS

1. Refer to TROUBLESHOOTING for comprehensive service

information provided with both heater and burner manuals.

NOT ENOUGH OR NO HOT WATER

1. Be certain the electrical disconnect switch serving the water

heater is in the ON position