14

VENT PIPE PREPARATION

1. INITIAL PREPARATION

A. Make sure the solvent cement you are planning to use is

designed for the specic application you are attempting.

B. Know the physical and chemical characteristics and limitations

of the PVC, PVC cellular core, ABS or CPVC piping materials

that you are about to use.

C. Know the reputation of your pipe and cement manufacturer

and their products.

D. Know your own qualications or those of your contractor. The

solvent welding technique of joining PVC, PVC cellular core,

ABS or CPVC pipe is a specialized skill just as any other pipe

tting technique.

E. Closely supervise the installation and inspect the nished

job before start-up.

F. Contact the manufacturer, supplier, or competent consulting

agency if you have any questions about the application or

installation of PVC, PVC cellular core, ABS or CPVC pipe.

G. Take the time and effort to do a professional job. Shortcuts will

only cause you problems and delays in start-up. The majority

of failures in these systems are the result of shortcuts and/or

improper joining techniques.

2. SELECTION OF MATERIALS

PRIMER

It is recommended that Tetrahydrofuran (THF) be used to prepare the

surfaces of pipe and ttings for solvent welding. Do not use water, rags,

gasoline or any other substitutes for cleaning PVC cellular core, ABS or

CPVC surfaces. A chemical cleaner such as MEK may be used.

CEMENT

The cement should be a bodied cement of approximately 500 to

1600 centipoise viscosity containing 10-20% (by weight) virgin PVC

material solvated with tetrahydrofuran (THF). Small quantities of

dimethyl formamide (DMF) may be included to act as a retarding

agent to extend curing time. Select the proper cement; Schedule 40

cement should be used for Schedule 40 pipe. Never use all purpose

cements, commercial glues and adhesives or ABS cement to join

PVC or CPVC pipe and ttings.

SAFETY PRECAUTION: PRIMERS AND CEMENTS ARE

EXTREMELY FLAMMABLE AND MUST NOT BE STORED OR

USED NEAR HEAT OR OPEN FLAME. ALSO, USE ONLY IN A

WELL-VENTILATED AREA.

CONTROLS AND SWITCHES

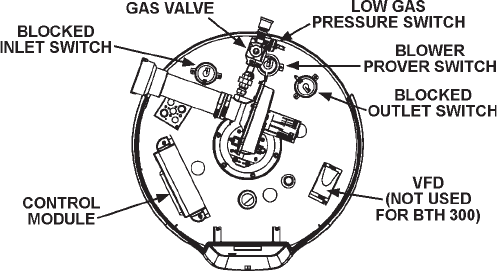

The BTH-300, 400 & 500 are equipped with four pressure switches.

These switches are essential to the safe and proper operation of the

unit. All switches are wired in series. The controller is set up to shut

the unit down whenever there is a failure of any of the switches. It

is important to understand the purpose of each switch.

BLOWER PROVER SWITCH

The Blower Prover Switch is provided on the heater to verify that

the fan is operating. It is a positive pressure switch whose electrical

contacts are normally open. When the fan increases the pressure

in the burner, the pressure switch will allow the electrical contacts

to close. The pressure switch is connected to the burner tap by a

piece of tygon tubing. This tubing must be connected in order for

the switch to change the electrical contacts. The controller requires

that the electrical contacts on this air ow switch be open before it

will allow the blower to come on. See Figure 13.

BLOCKED OUTLET PROVER SWITCH

The Blocked Outlet Prover Switch is set up to shut the unit off when

a build-up of positive pressure in the exhaust vent pipe occurs.

This switch is a positive pressure switch that requires an increase

in pressure to change the electrical contacts from normally closed

to open. When this switch prevents the unit from igniting, most

likely the exhaust is blocked by some means. Check to see if the

condensate is allowed to ow freely from the exhaust elbow and

for obstructions in the exhaust venting and exhaust vent terminal.

See Figure 13.

BLOCKED INLET PROVER SWITCH

The Blocked Inlet Prover Switch is set up to shut the unit off when

a build-up of negative pressure in the intake vent pipe occurs. This

switch is a negative pressure switch that requires an increase in

negative pressure to change the electrical contacts from normally

closed to open. The switch is connected to the pressure tap on

the ange connected to the inlet of the blower. When this switch

prevents the unit from igniting, most likely the intake is blocked by

some means. Check to see if there is no more than seventy (70)

equivalent feet (24.8m) of four inch PVC vent pipe on the intake. Also

verify that the intake and intake vent terminal is free of obstructions

that may prevent air from entering the unit. See Figure 13.

LOW GAS PRESSURE SWITCH

The Low Gas Switch (LGS) is a single-pole, normally open pressure

switch that will close its contacts when a rising pressure of 4.6 in.

W.C. (1.25 Kpa) is encountered. The contacts will open when the

pressure falls below the xed set point of 4.6 in. W.C. (1.25 Kpa)

The LGS monitors the gas supply pressure to the heater. If the

gas supply falls below 4.6 in. W.C. (1.25 Kpa), the main burner is

extinguished (if heater is running) or the heater will not start up.

NOTE: LOW GAS SWITCH IS LOCATED ON INLET SIDE OF GAS

VALVE. See Figure 13.

FIGURE 13.

ON/OFF SWITCH

The ON/OFF Switch is a single-pole, single-throw rocker switch. This

switch provides 120VAC from the line source to the heater.