12

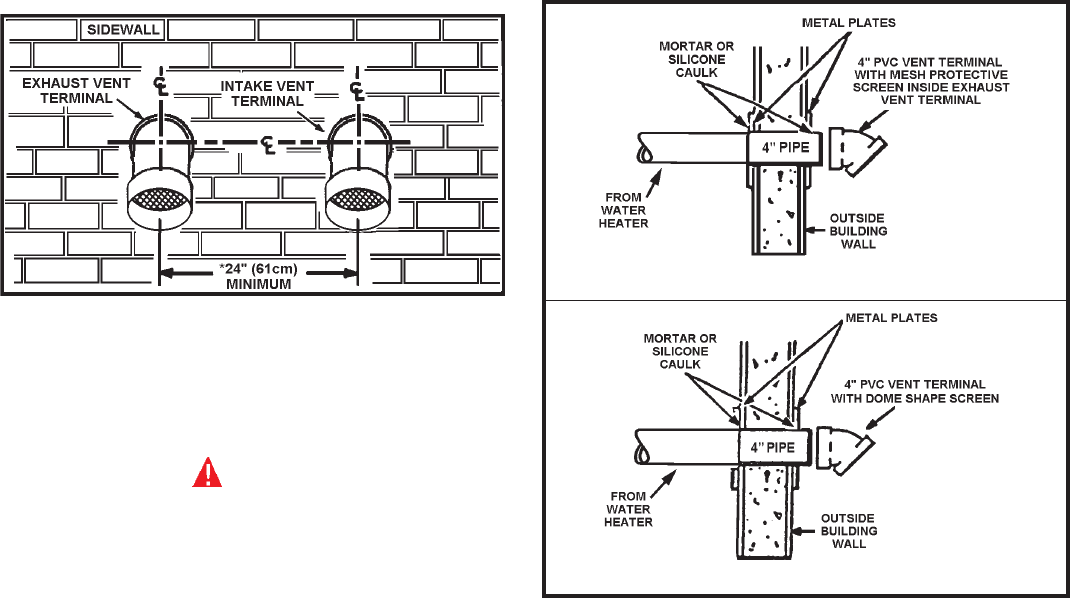

2. The horizontal centerline of the intake vent terminal may not be

located lower than the horizontal centerline of the exhaust vent

terminal (see Figure 9).

FIGURE 9.

INSTALLATION SEQUENCE

For installations in the City of Los Angeles, California Category IV

PVC Pipe such as that manufactured by Brownline Pipe Company,

must be used as vent pipe material.

CAUTION

Vent terminals supplied with the heater must be used.

NOTE: BEFORE BEGINNING INSTALLATION OF ANY VENT

PIPE READ THE VENT PIPE MANUFACTURER'S INSTALLATION

INSTRUCTIONS.

1. After the points of termination have been determined, use the

cover plates as templates to mark the holes for the vent pipes

to be inserted through the wall. BEWARE OF CONCEALED

WIRING AND PIPING INSIDE OF WALL.

2. If the vent terminals are being installed on the outside of a nished

wall, it may be easier to mark both the inside and outside wall.

Align the holes by drilling a hole through the center of the template

from the inside through to the outside. The template can now be

positioned on the outside wall using the drilled holes as a centering

point for the template.

3. A) MASONRY SIDE WALLS

Chisel an opening approximately 1/2" (1.3 cm) larger than the

marked circle.

B) WOODEN SIDE WALLS

Drill a pilot hole approximately one quarter inch outside of the

marked circle. This pilot hole is used as a starting point for a

saws-all or sabre saw blade. Cut around the marked circle staying

approximately one quarter inch outside of the line. (This will allow

the vent pipe to easily slide through the opening. The resulting

gap will be covered by the vent terminal cover plates.) Repeat

this step on the inside wall if necessary.

4. Cut a length of PVC pipe about 3.5" (8.9 cm) longer than the wall

thickness at the opening.

5. Glue the intake vent terminal to the section of the pipe.

6. Slide the wall plate over the pipe to stop against intake vent terminal.

7. Place a bead of caulking (not supplied) around the gap between

the pipe and the wall. Place some of the caulking on the back of

the plate to hold it against the wall after installation.

8. If the vent pipe is installed up to the wall, with a coupling on the

end against the wall opening, the pipe with the vent terminal

can be prepared for gluing before inserting through the wall.

Slide the pipe through the wall and insert into coupling on the

other side of the wall, making sure that the vent terminal ends

up pointed in the correct position. See Figure 10.

EXHAUST VENT TERMINAL

INTAKE VENT TERMINAL

FIGURE 10.

VERTICAL VENT TERMINAL INSTALLATION

IMPORTANT

WHEN TERMINATING THROUGH A ROOF, THE FOLLOWING

SPECIFICATIONS PERTAINING TO TERMINAL LOCATION MUST

BE FOLLOWED.

1. Proper support must be provided for all pipe protruding through

the roof.

2. The vertical roof terminations should be sealed with a plumbing

roof boot or equivalent ashing.

3. The intake vent termination and the exhaust vent termination

must penetrate the same side of roof.

4. The center line of the intake vent termination and the center

line of the exhaust vent termination must be no closer than

24" (61cm).

5. The intake vent terminal and the exhaust vent terminal must be

oriented facing downward and the same direction.

The specications are displayed in Figure 11.

NOTE: Exhaust vent terminal is installed using the same procedure.

INSTALLATION SEQUENCE

NOTE: BEFORE BEGINNING INSTALLATION OF ANY VENT

PIPE, READ “VENT PIPE PREPARATION” SECTION.

1. After the points of termination have been determined, use the

cover plates as templates to mark the holes for the vent pipes to

be inserted through the roof.