20

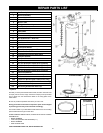

B. Deburring

Use a knife, plastic pipe deburring tool, or fi le to remove burrs

from the end of small diameter pipe. Be sure to remove all burrs

from around the inside as well as the outside of the pipe. A slight

chamfer (bevel) of about 10°-15° should be added to the end to

permit easier insertion of the pipe into the end of the fi tting. Failure

to chamfer the edge of the pipe may remove cement from the fi tting

socket, causing the joint to leak.

STEP B

C. Test dry fi t of the joint

Tapered fi tting sockets are designed so that an interfaced fi t should

occur when the pipe is inserted about 1/3 to 2/3 of the way into

the socket. Occasionally, when pipe fi tting dimensions are at the

tolerance extremes, it will be possible to fully insert dry pipe to the

bottom of the fi tting socket. When this happens, a suffi cient quantity

of cement must be applied to the joint to fi ll the gap between the

pipe and fi tting. The gap must be fi lled to obtain a strong, leak-free

joint.

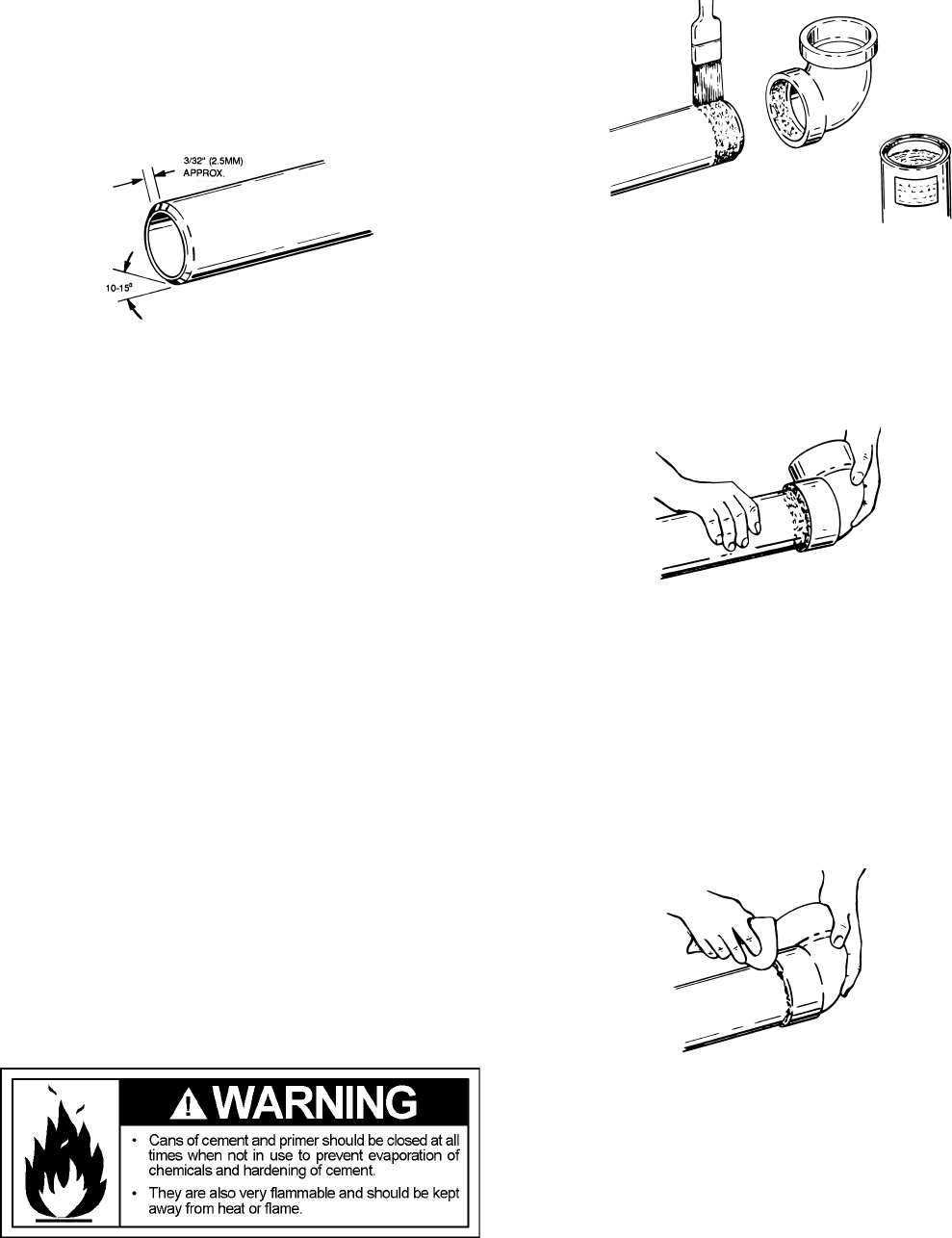

D. Inspection, cleaning, priming

Visually inspect the inside of the pipe and fi tting sockets and

remove all dirt, grease or moisture with a clean dry rag. If wiping

fails to clean the surfaces, a chemical cleaner must be used.

Check for possible damage such as splits or cracks and replace

if necessary.

Depth-of-entry

Marking the depth of entry is a way to check if the pipe has reached

the bottom of the fi tting socket in Step F. Measure the fi tting depth

and mark this distance on the pipe O.D. You may want to add

several inches to the distance and make a second mark as the

primer and cement will most likely destroy your fi rst one.

Apply primer to the surface of the pipe and fi tting socket with a

natural bristle brush. This process softens and prepares the PVC

or CPVC for the solvent cementing step. Move quickly and without

hesitation to the cementing procedure while the surfaces are still

wet with primer.

E. Application of solvent cement

• Apply the solvent cement evenly and quickly around the outside

of the pipe at a width a little greater than the depth of the fi tting

socket.

• Apply a light coat of cement evenly around the inside of the

fi tting socket. Avoid puddling.

• Apply a second coat of cement to the pipe end.

STEP E

F. Joint assembly

Working quickly, insert the pipe into the fi tting socket bottom and

give the pipe or fi tting a 1/4 turn to evenly distribute the cement.

Do not continue to rotate the pipe after it has hit the bottom of the

fi tting socket. A good joint will have suffi cient cement to make a

bead all the way around the outside of the fi tting hub. The fi tting

will have a tendency to slide back while the cement is still wet so

hold the joint together for about 15 seconds.

STEP F

G. Cleanup and joint movement

Remove all excess cement from around the pipe and fi tting with a

dry cotton rag. This must be done while the cement is still soft.

The joint should not be disturbed immediately after the cementing

procedure, and suffi cient time should be allowed for proper curing of

the joint. Exact drying time is diffi cult to predict because it depends

on variables such as temperature, humidity and cement integrity.

For more specifi c information, you should contact your solvent

cement manufacturer.

STEP G